Embed presentation

Downloaded 23 times

![Relating Stress and Strain

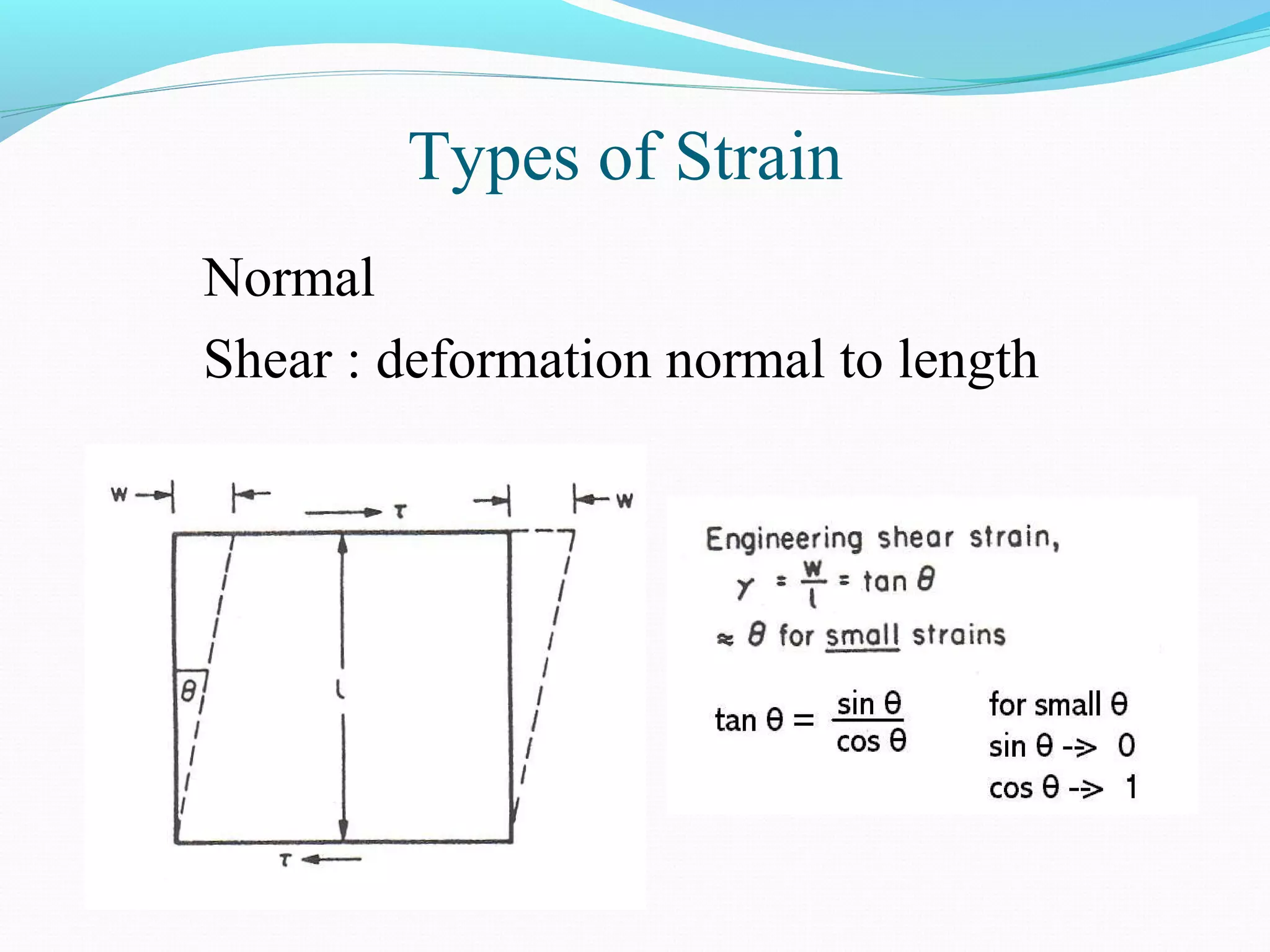

Shear

Hooke’s Law

τ = G γ

Shear Modulus

G = E / [2 (1+ ν )]

τ = shear stress

G = shear modulus

γ = shear strain](https://image.slidesharecdn.com/stressandstrain-sectionc-161124193402/75/Stress-and-strain-section-c-16-2048.jpg)

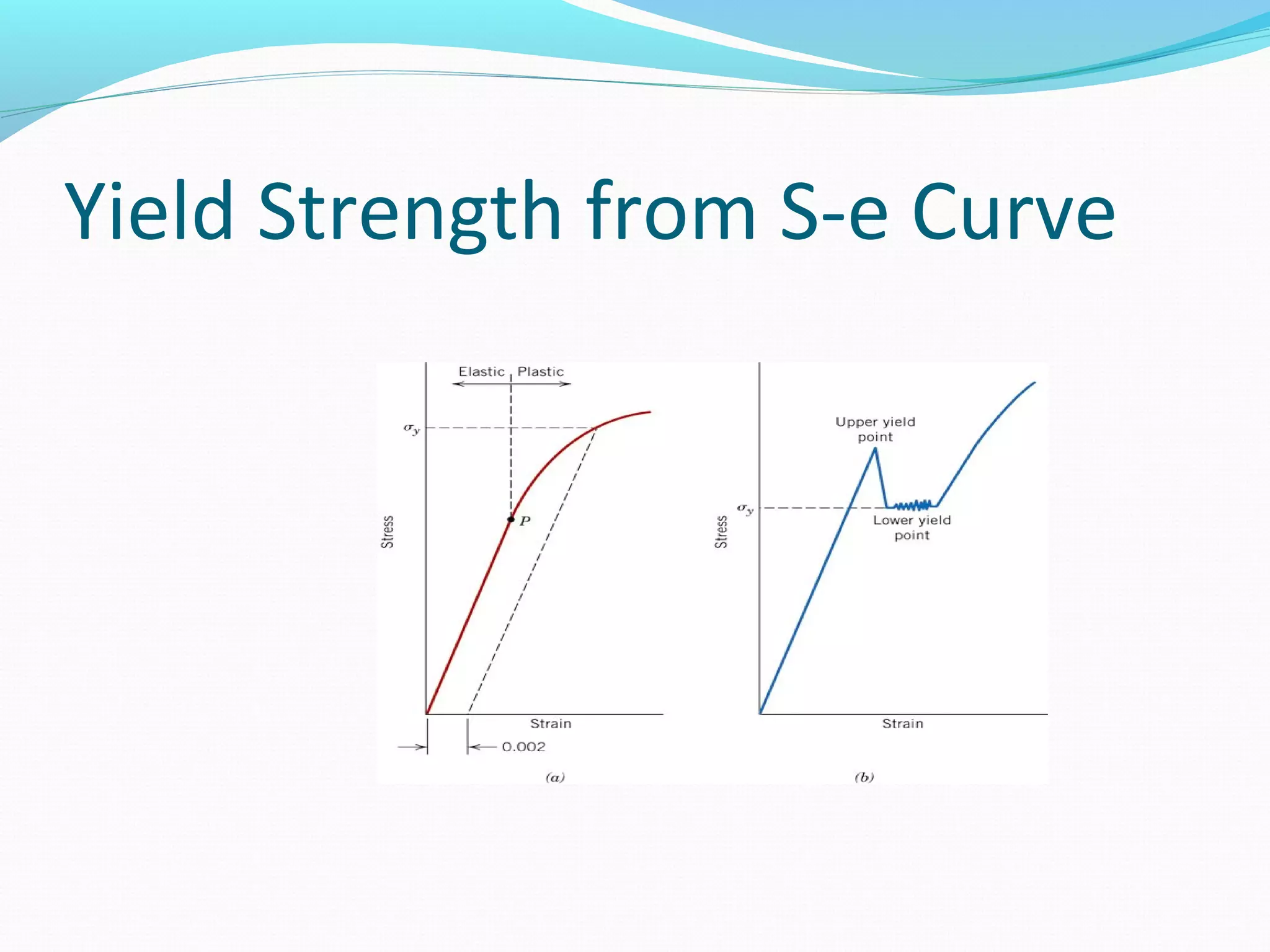

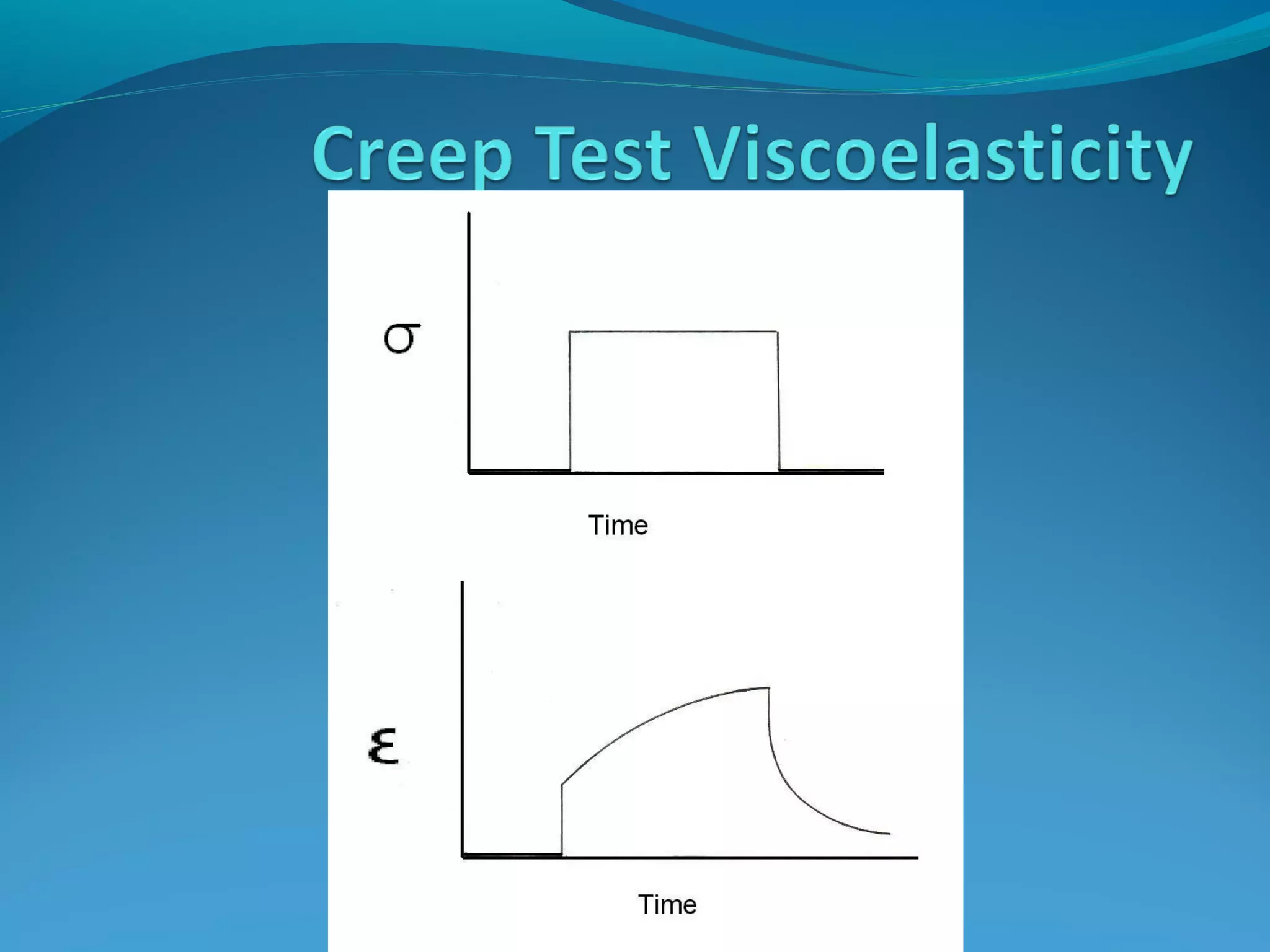

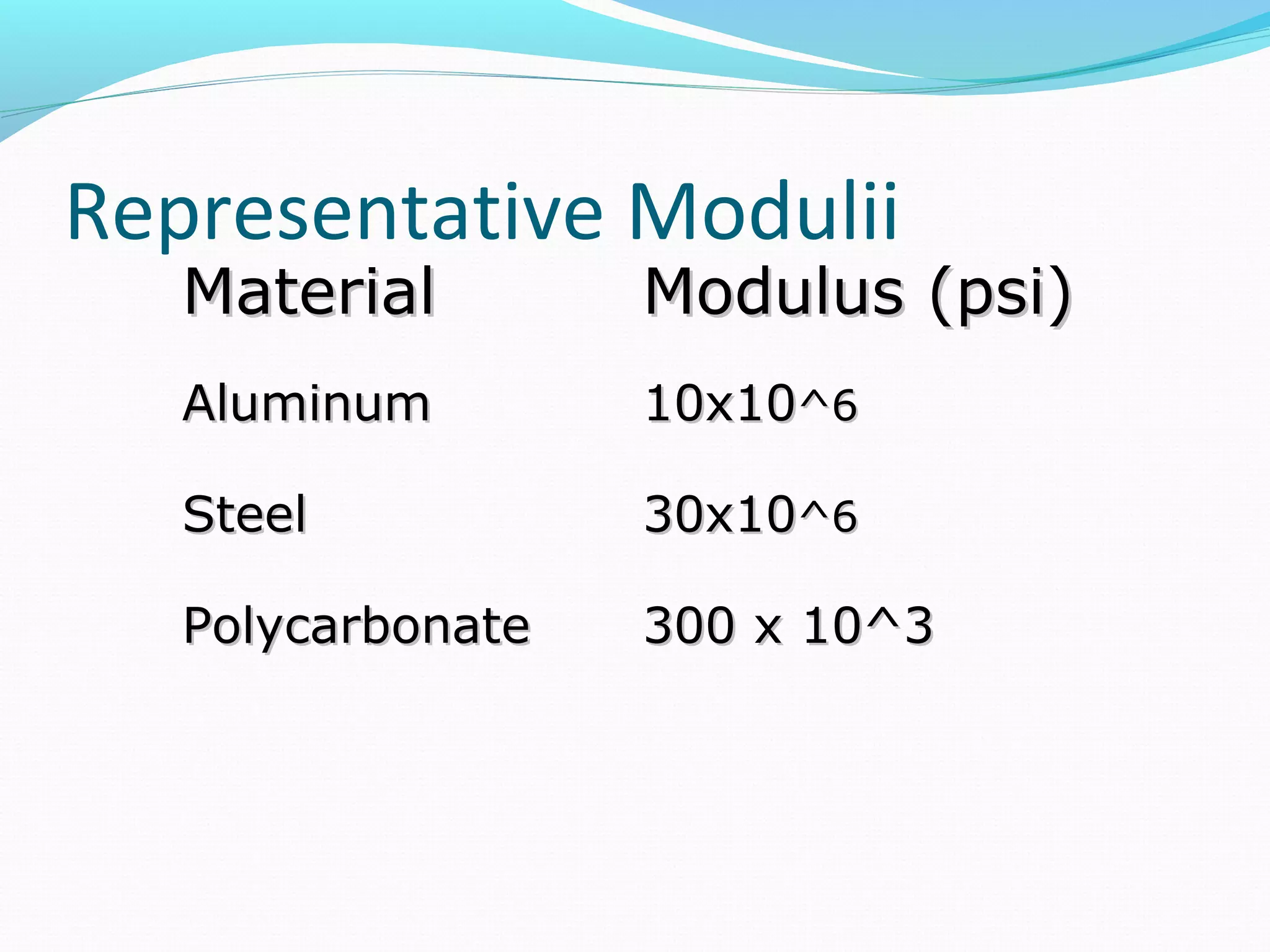

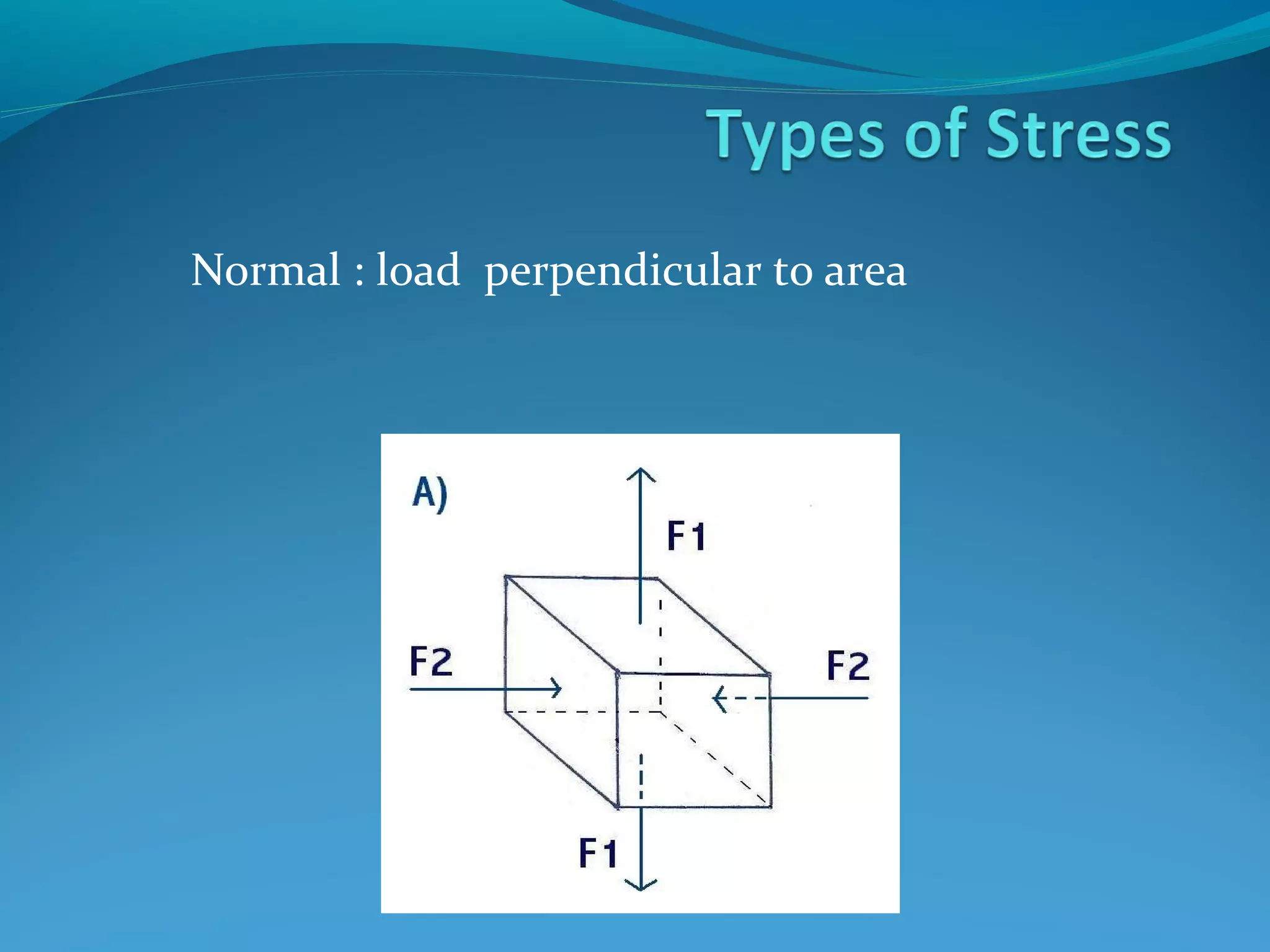

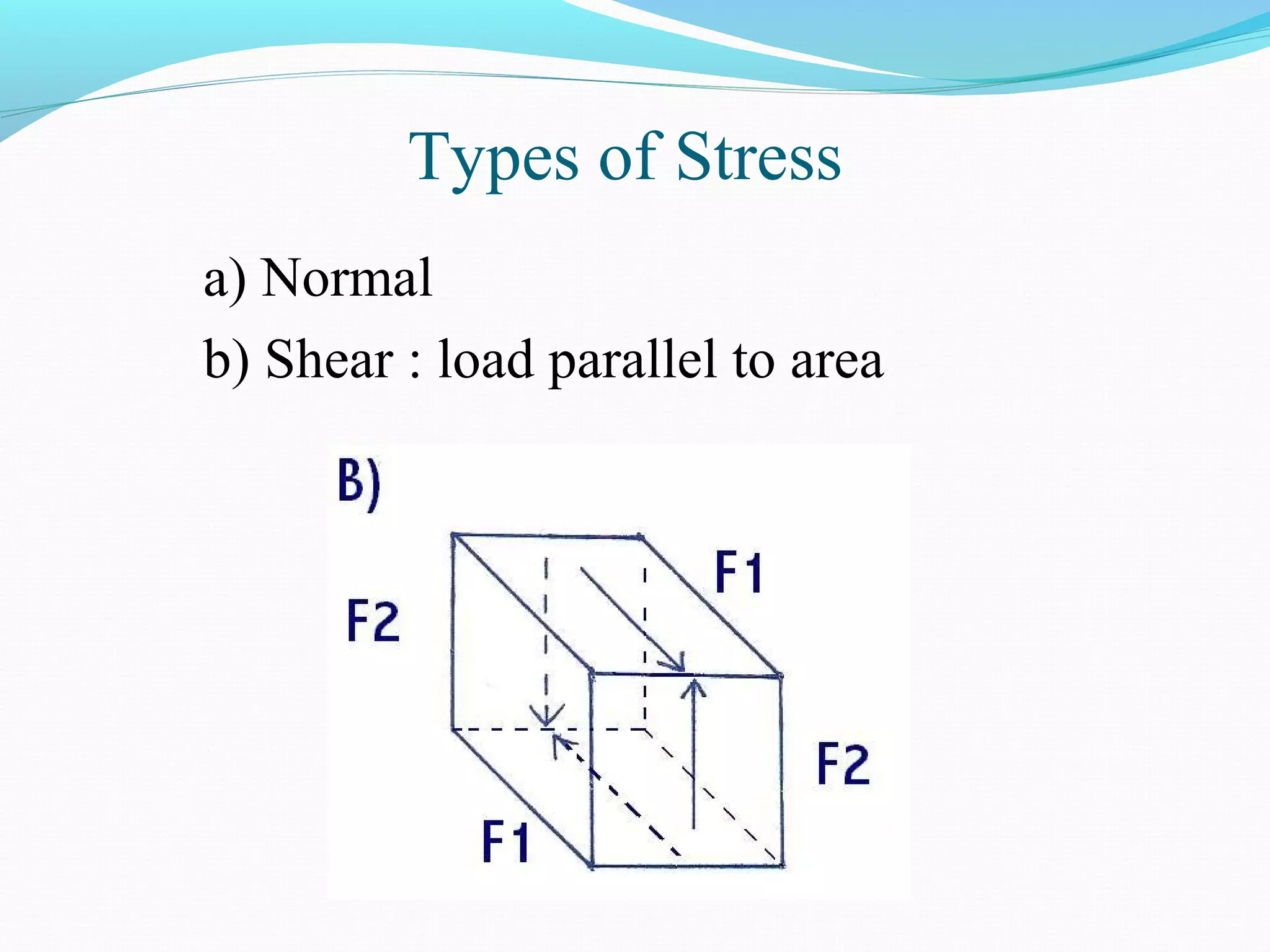

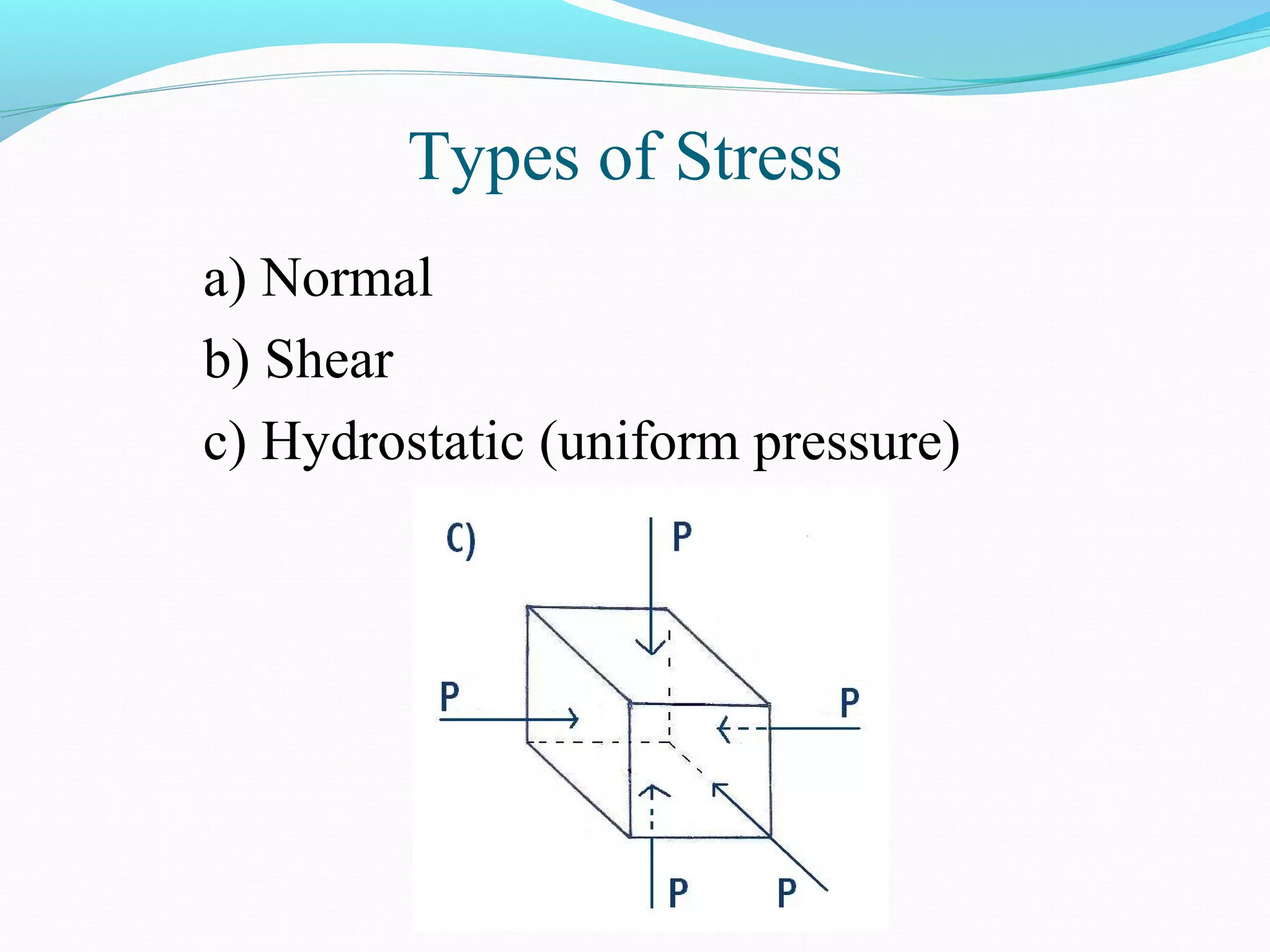

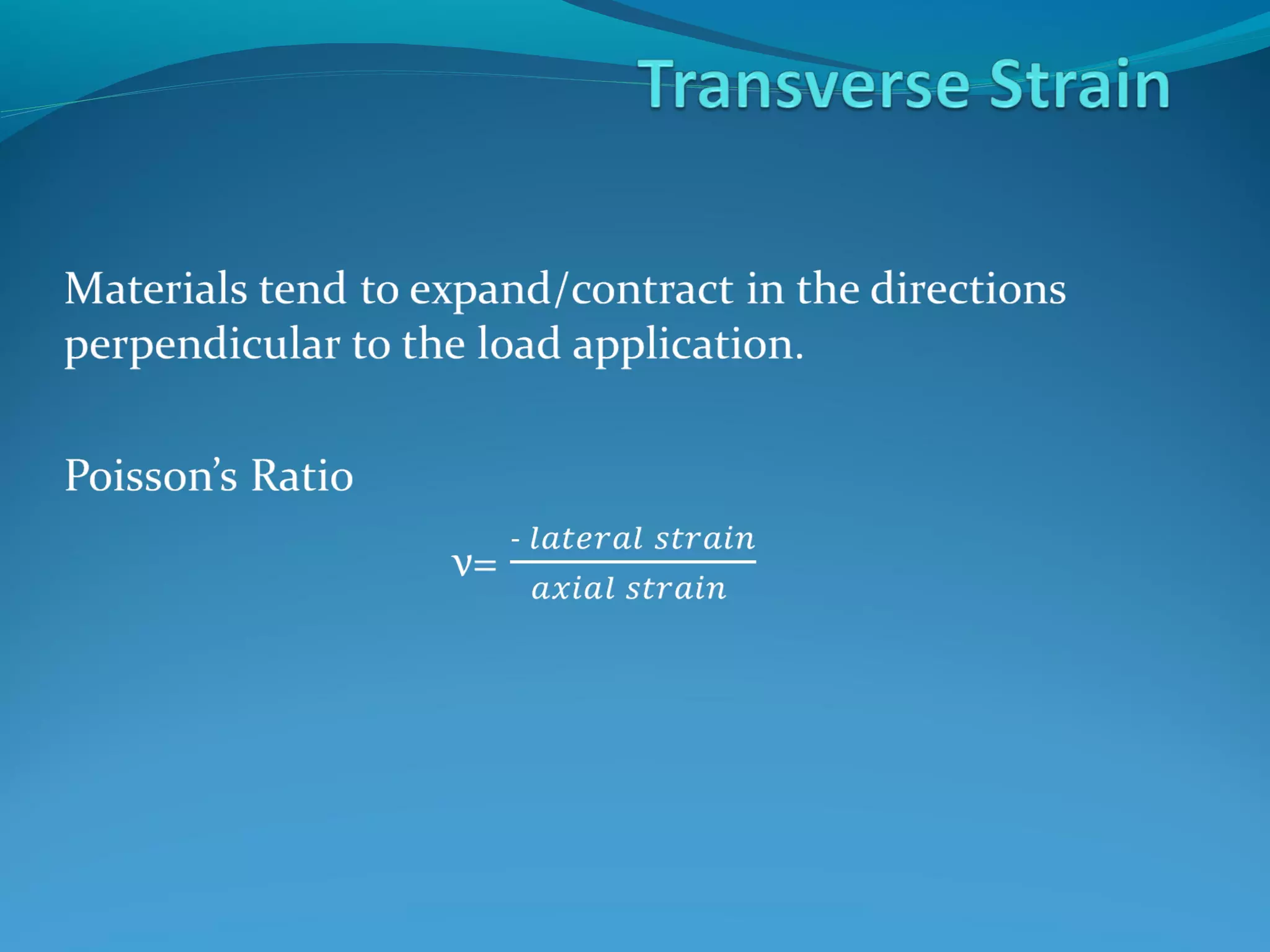

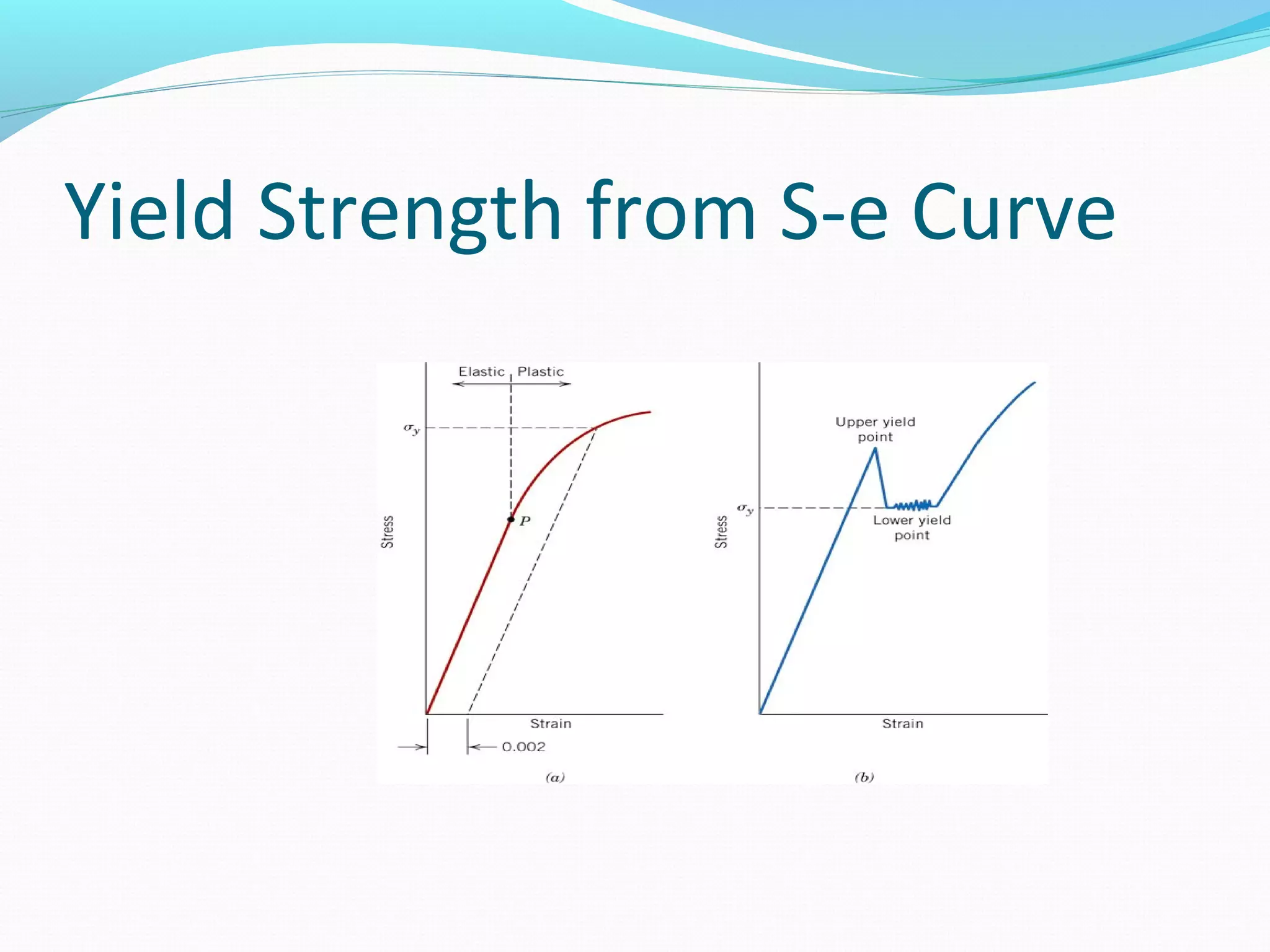

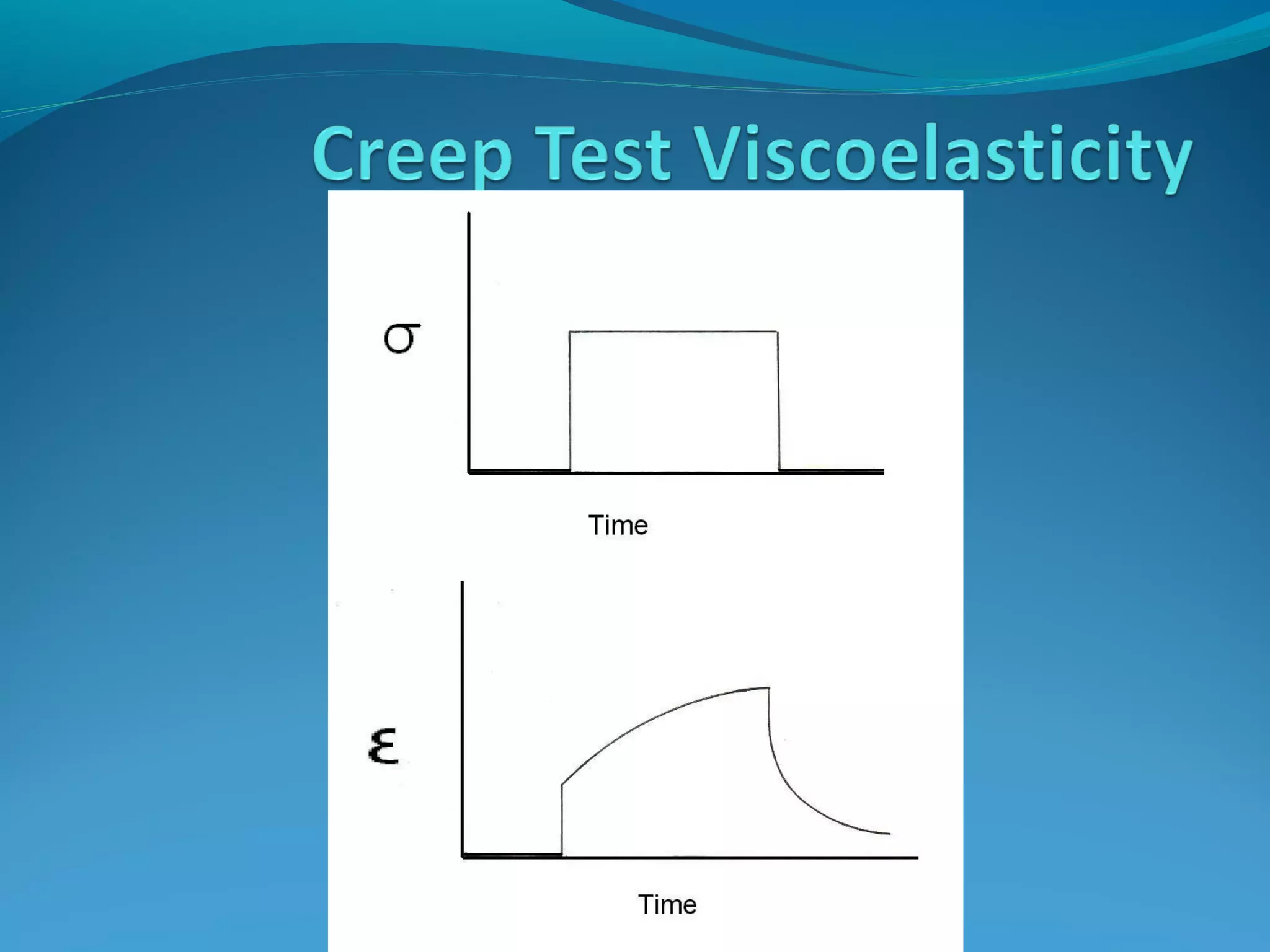

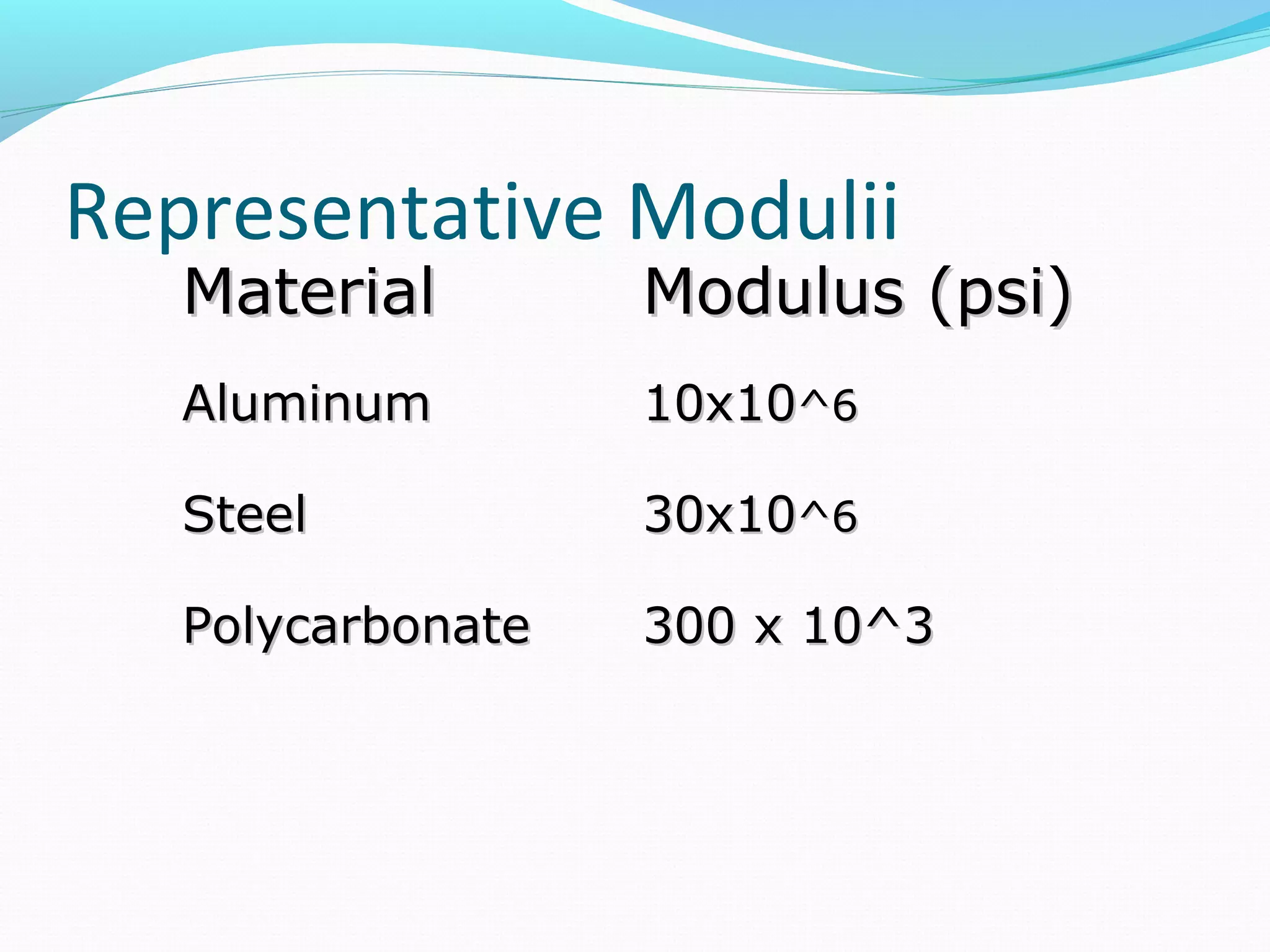

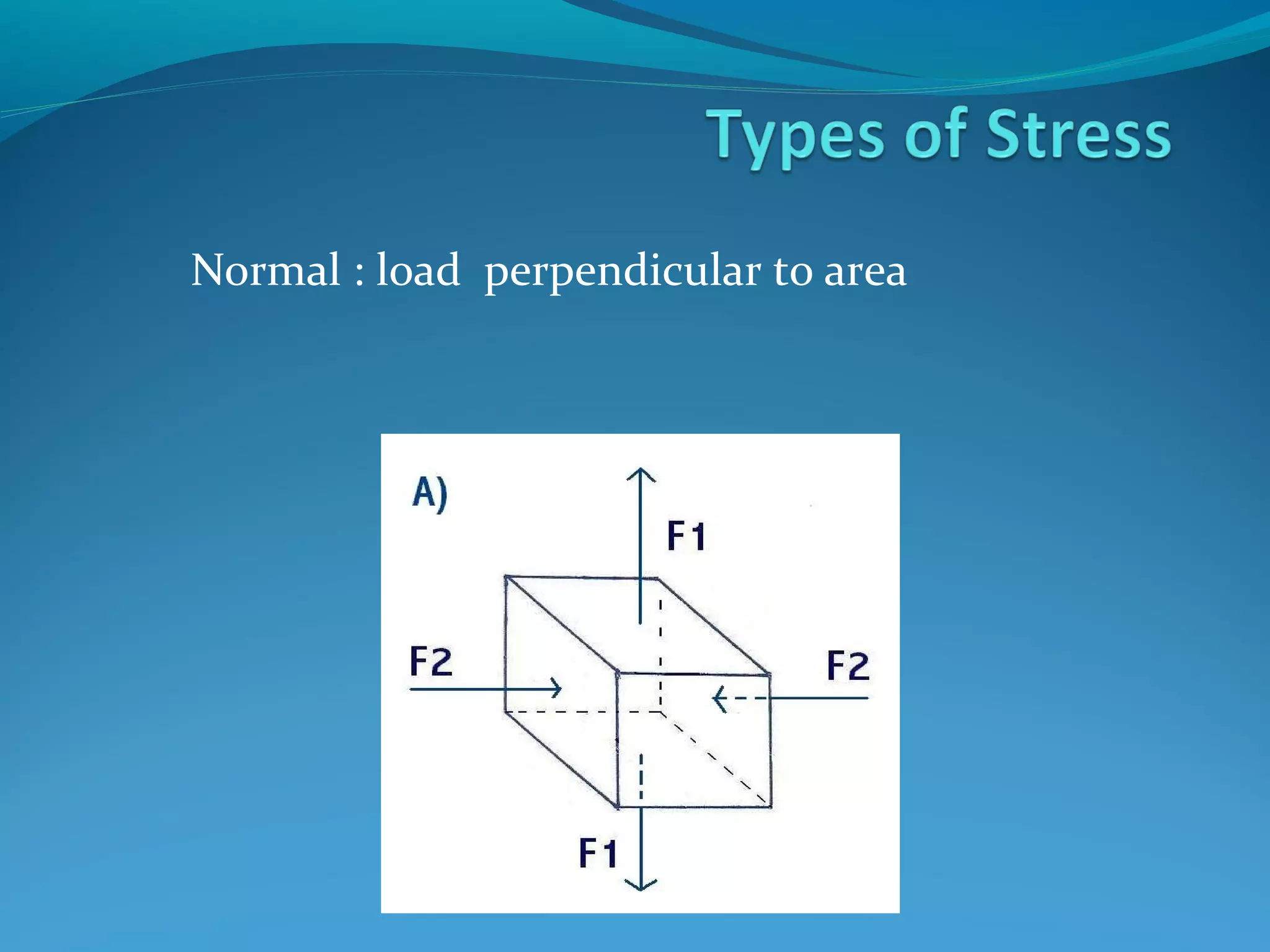

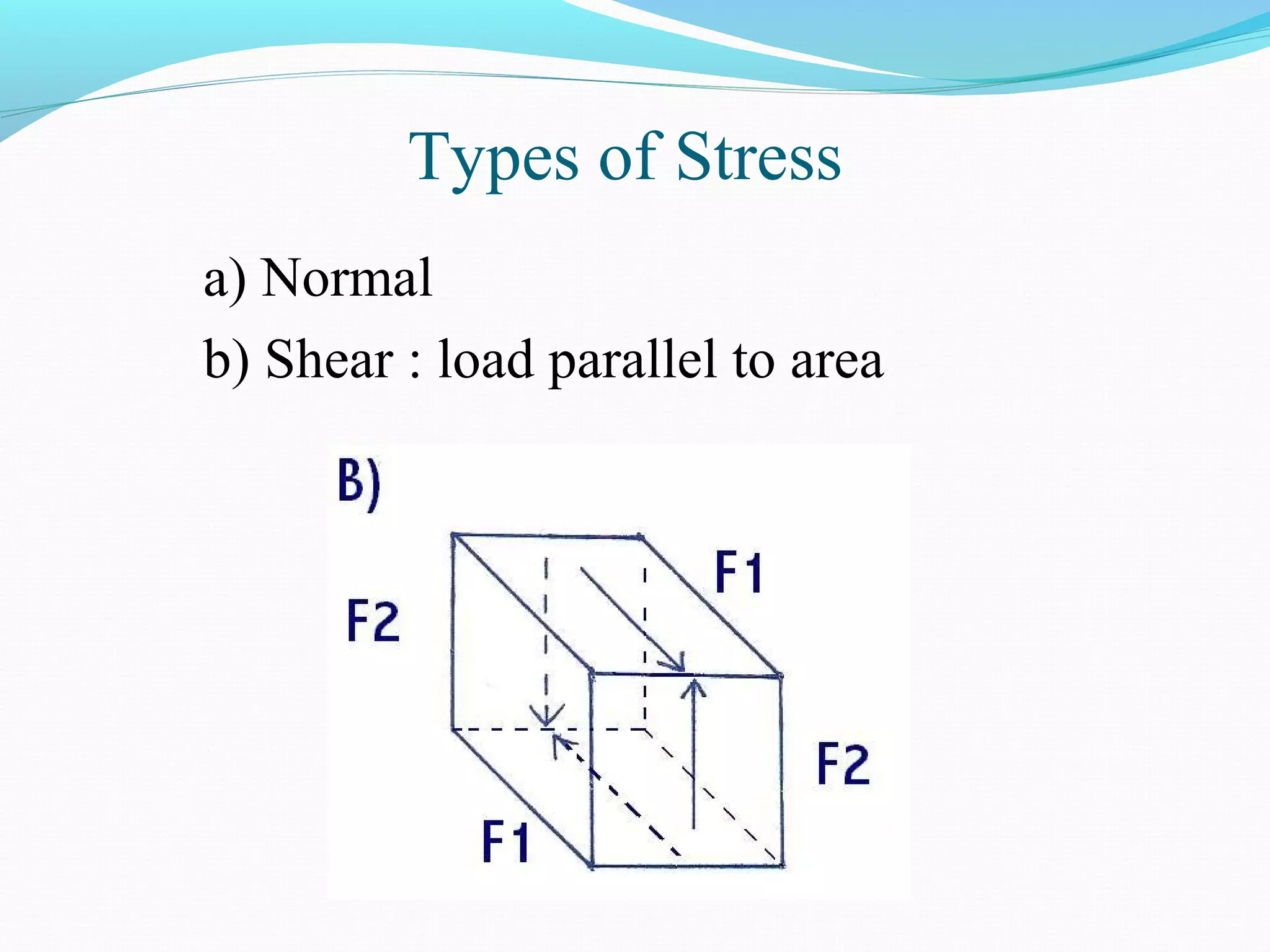

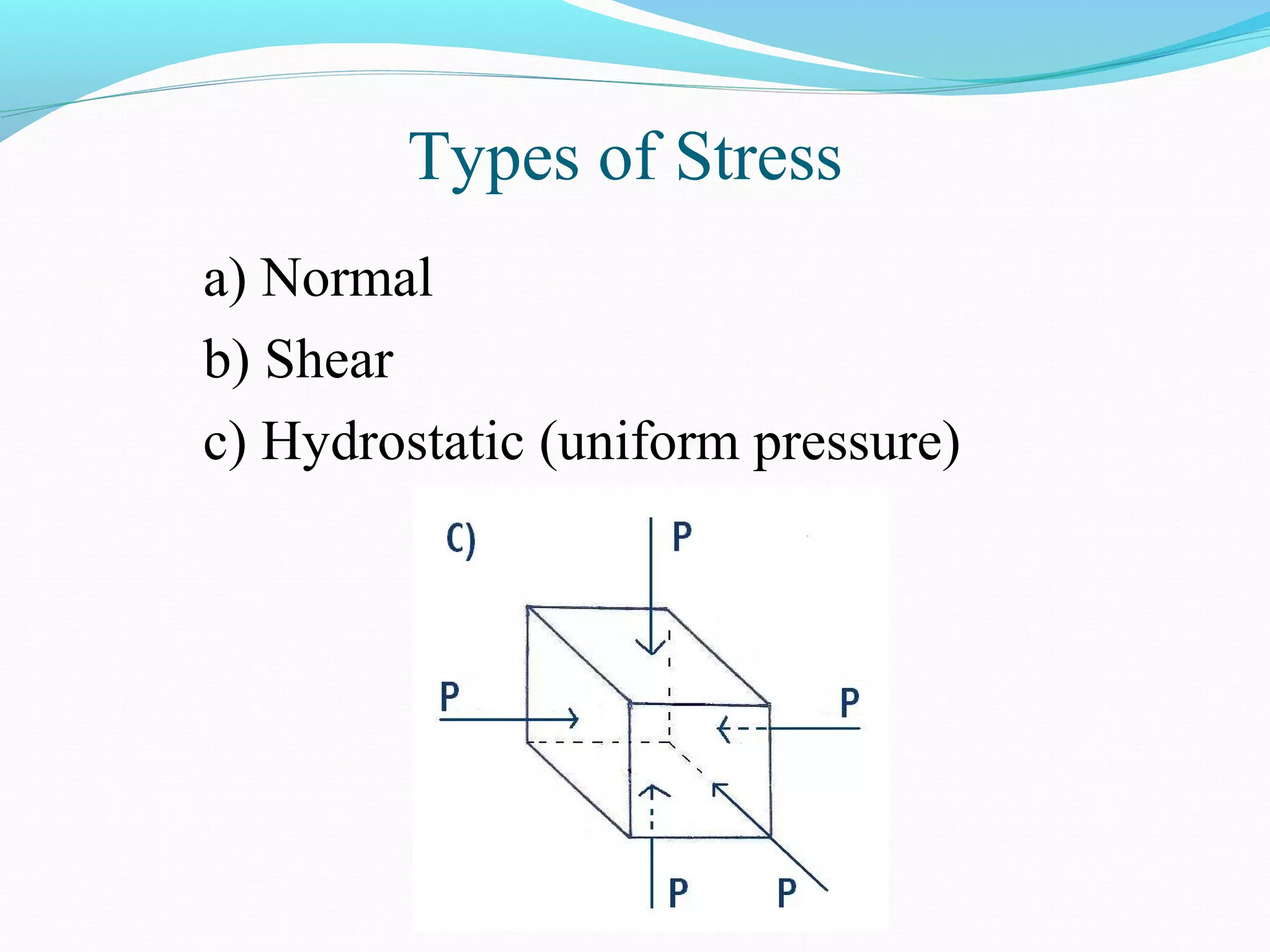

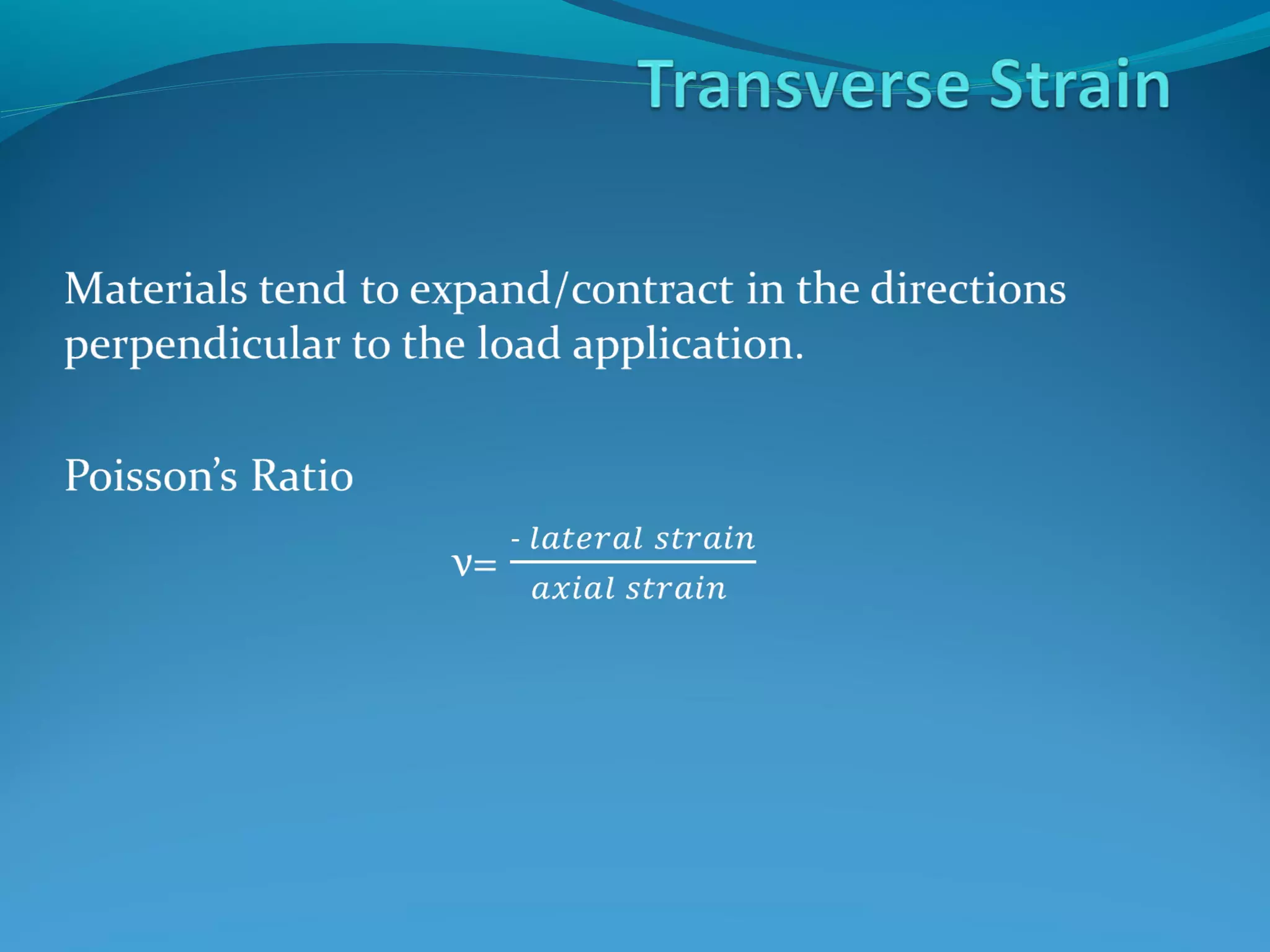

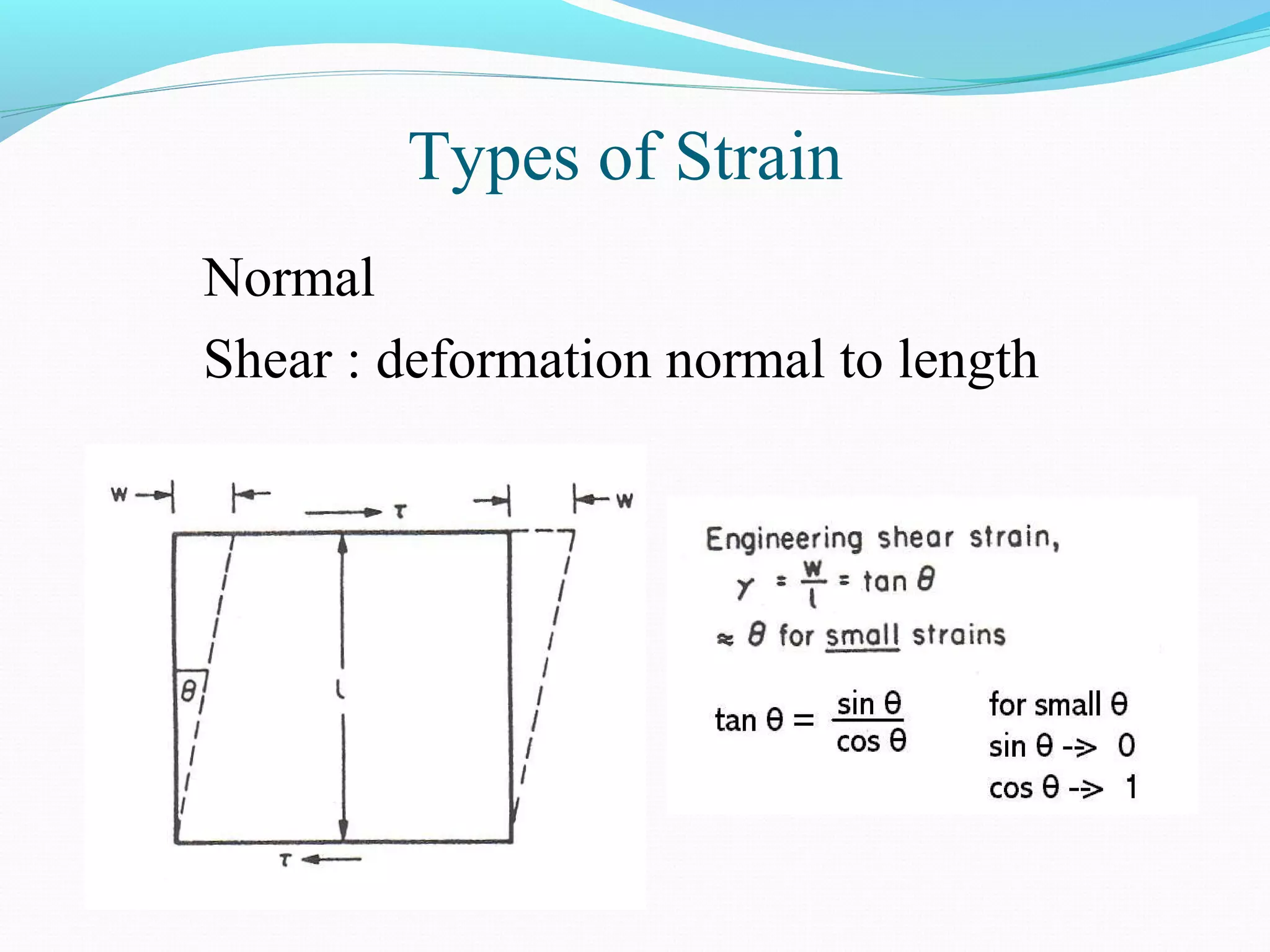

The document outlines the fundamental concepts of stress and strain, including definitions, types, and relationships such as Hooke’s law. It explains the calculation of material parameters from stress-strain curves and describes elastic and plastic deformation. Additionally, it includes specific values for Poisson's ratio and material moduli for various materials.

![Relating Stress and Strain

Shear

Hooke’s Law

τ = G γ

Shear Modulus

G = E / [2 (1+ ν )]

τ = shear stress

G = shear modulus

γ = shear strain](https://image.slidesharecdn.com/stressandstrain-sectionc-161124193402/75/Stress-and-strain-section-c-16-2048.jpg)