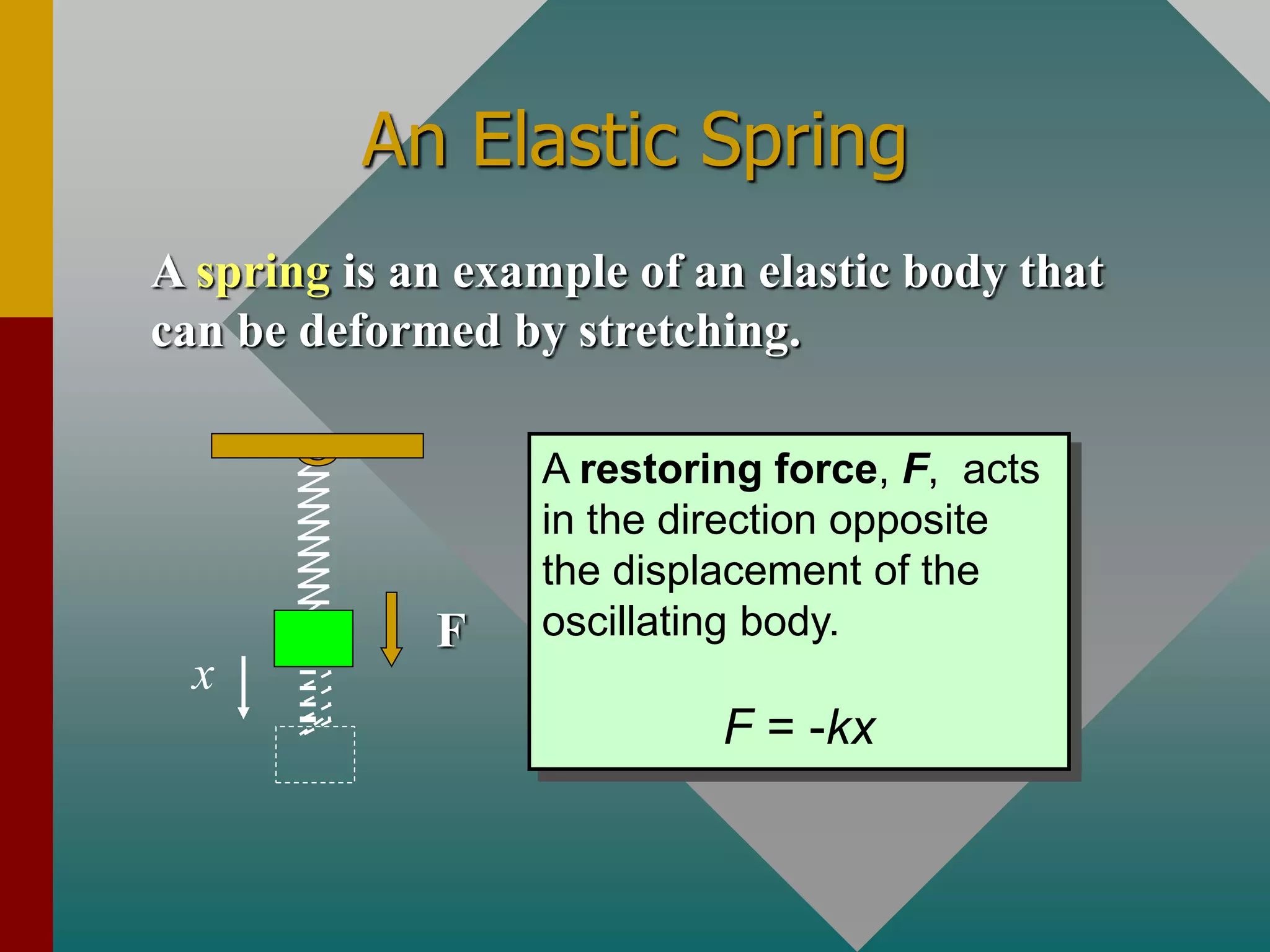

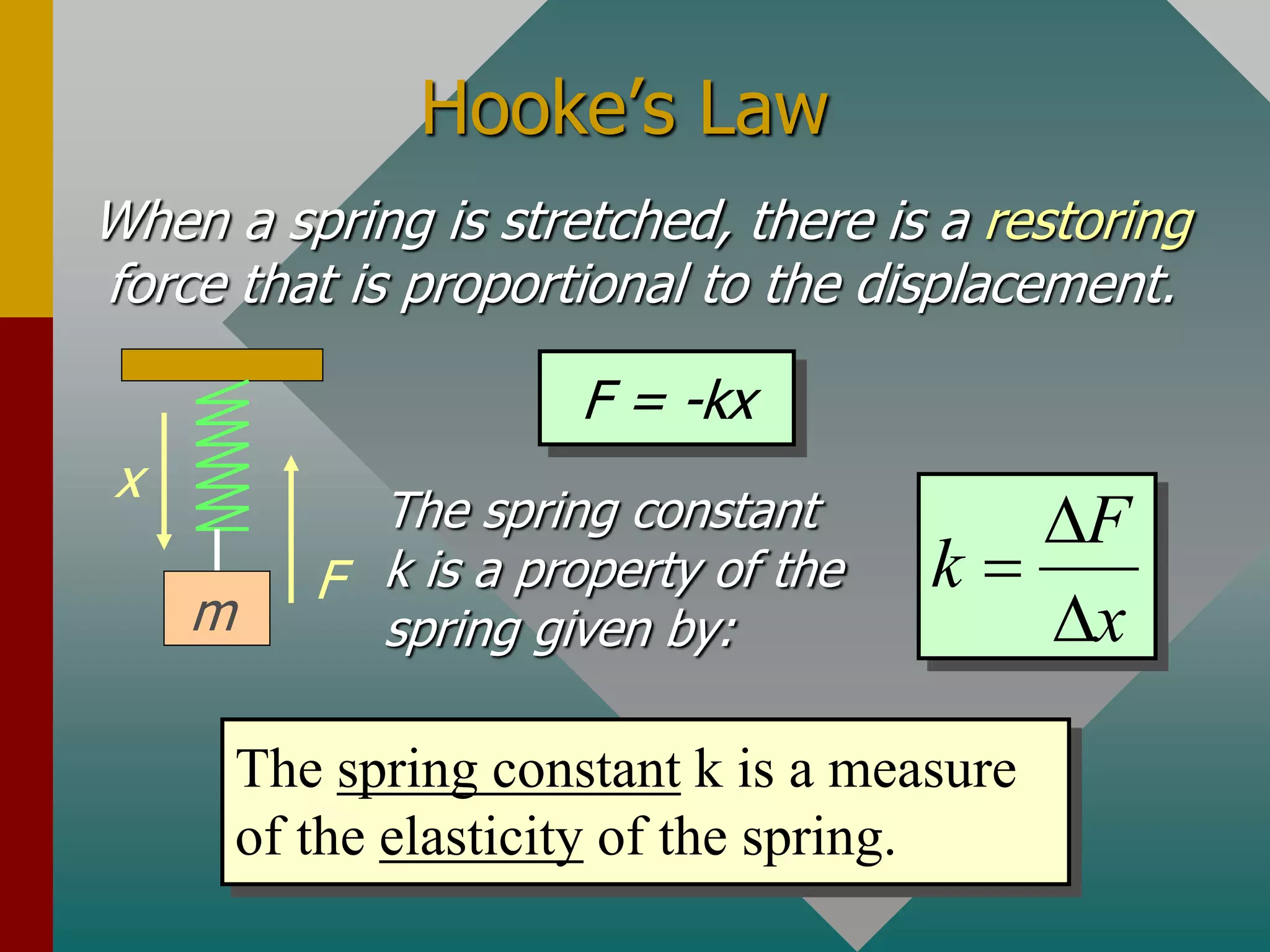

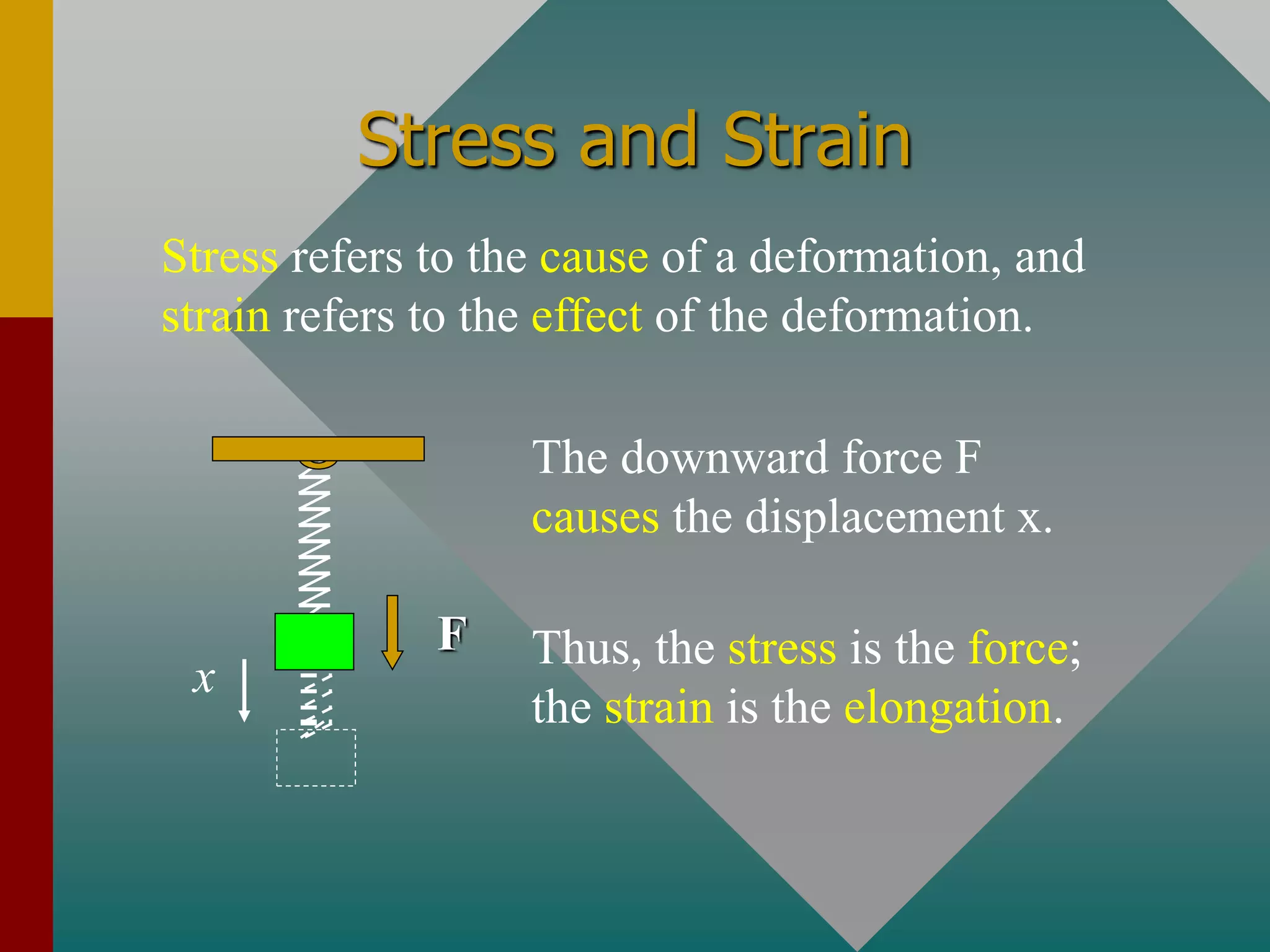

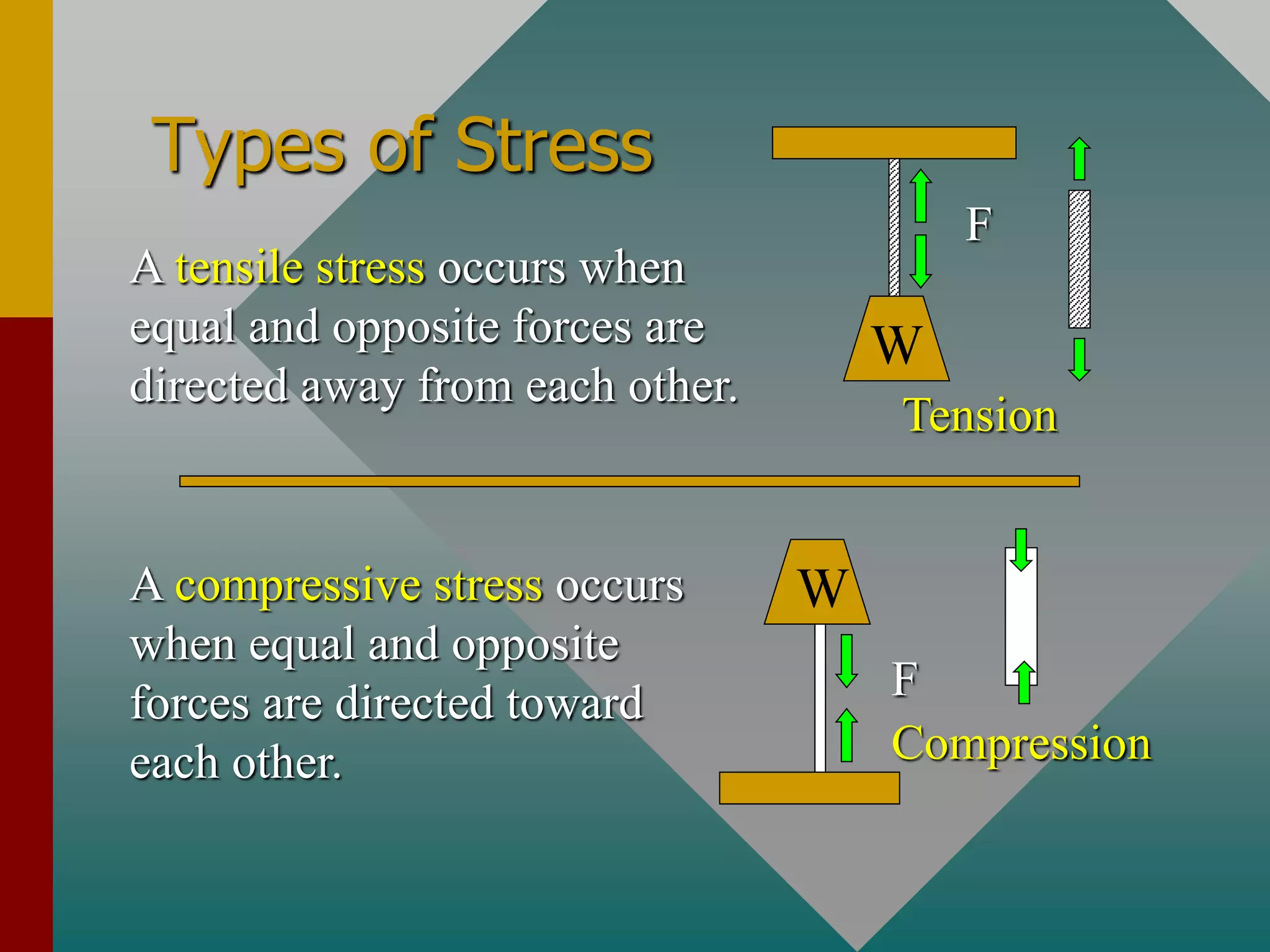

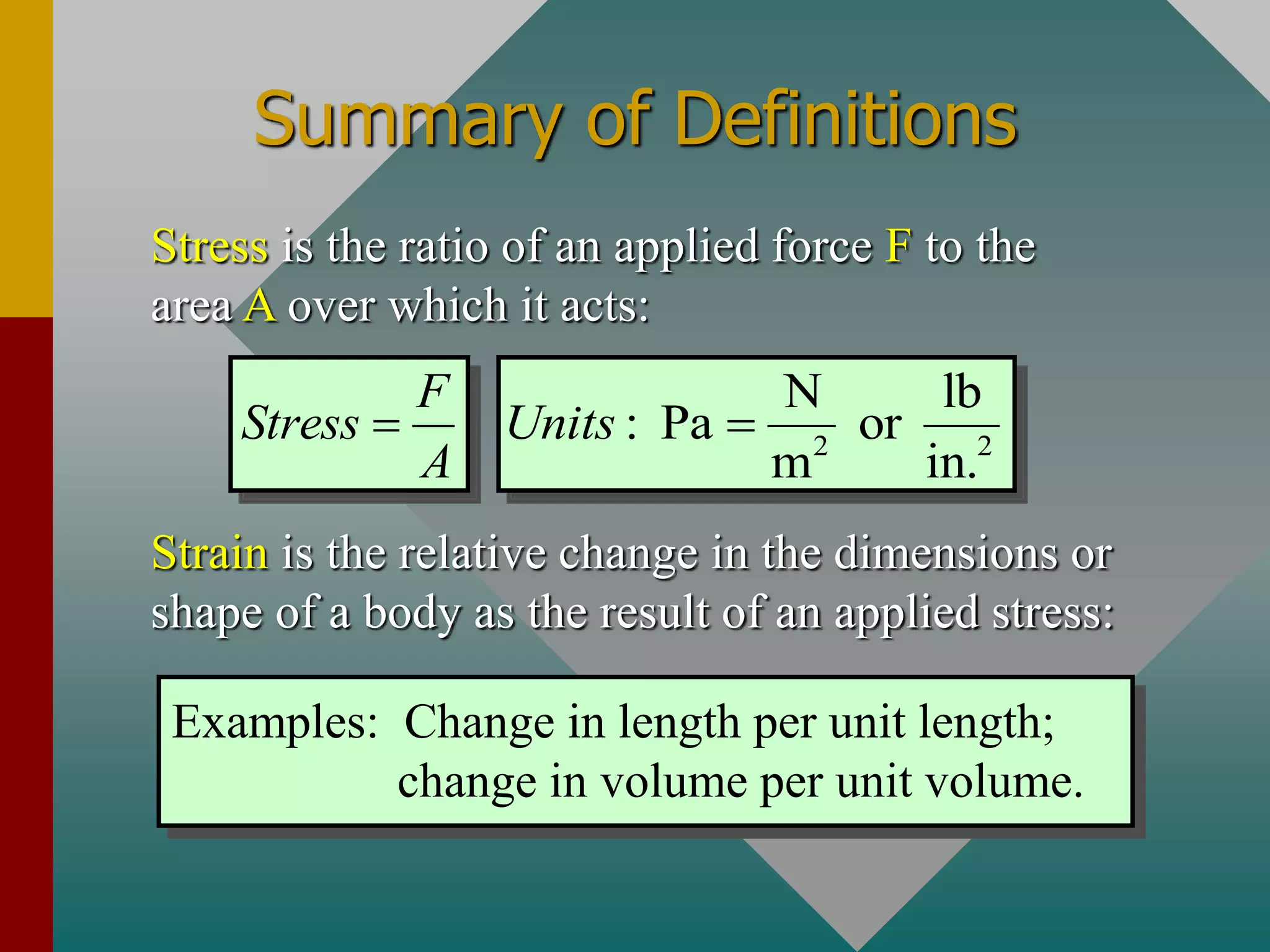

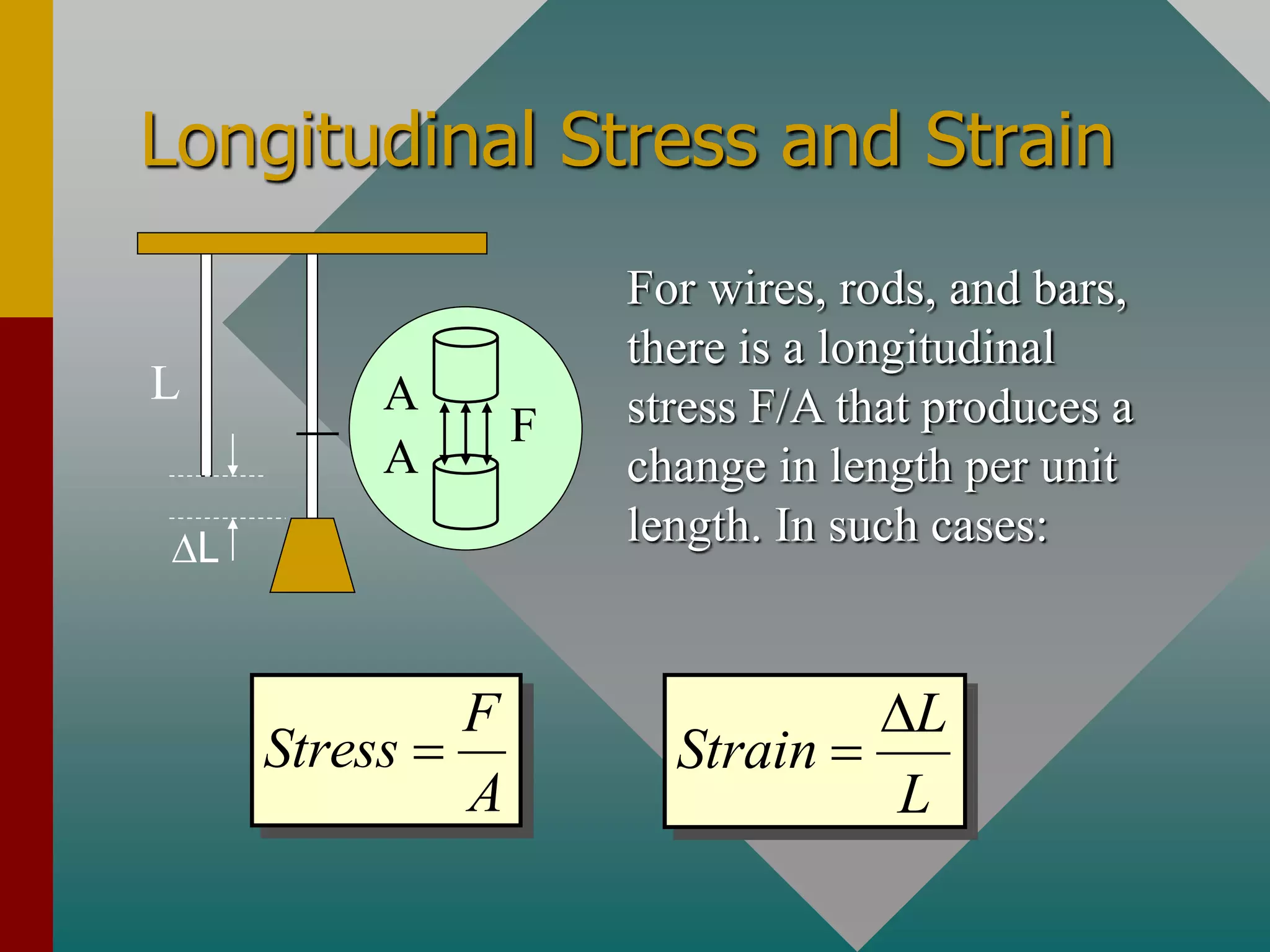

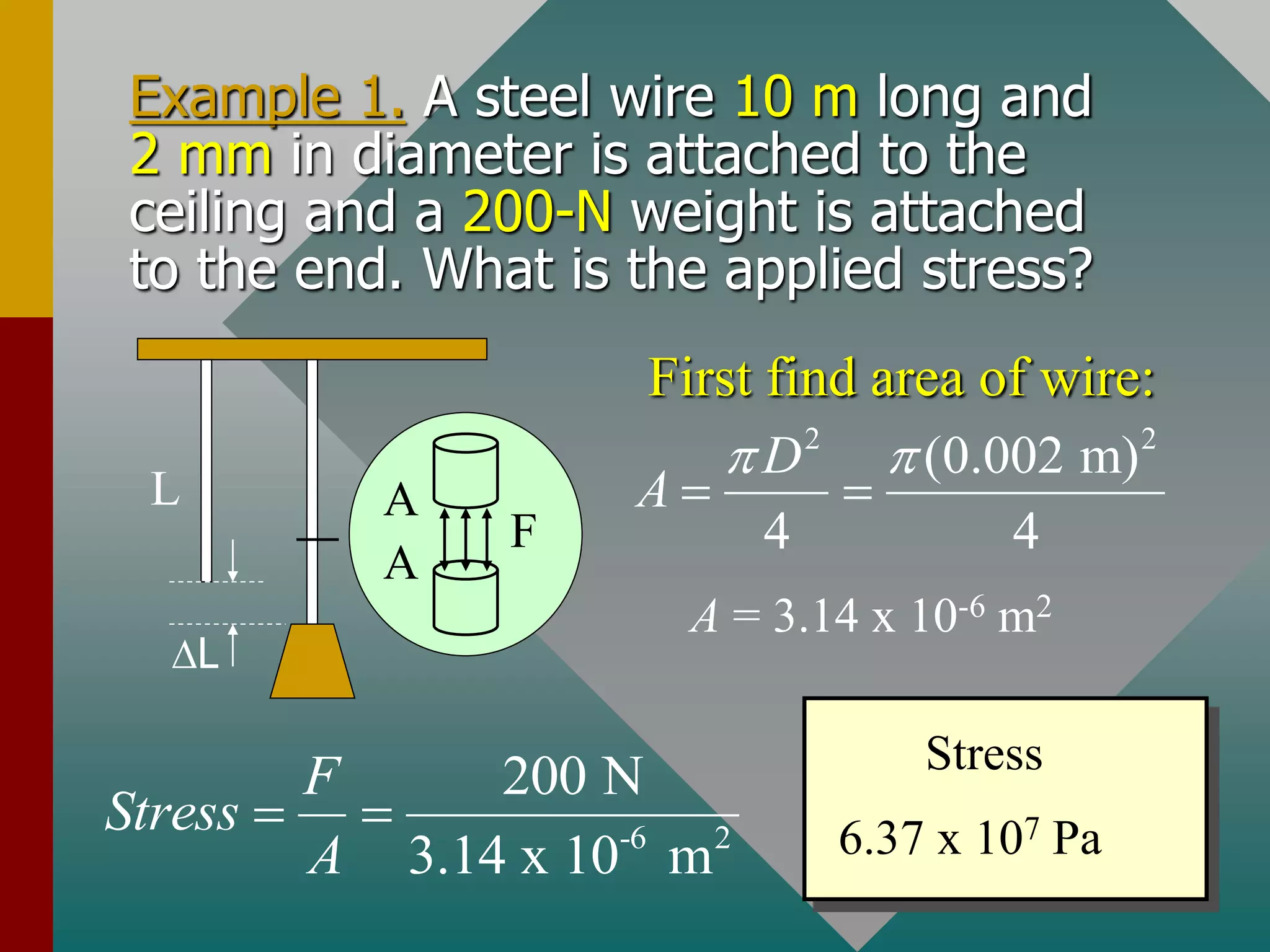

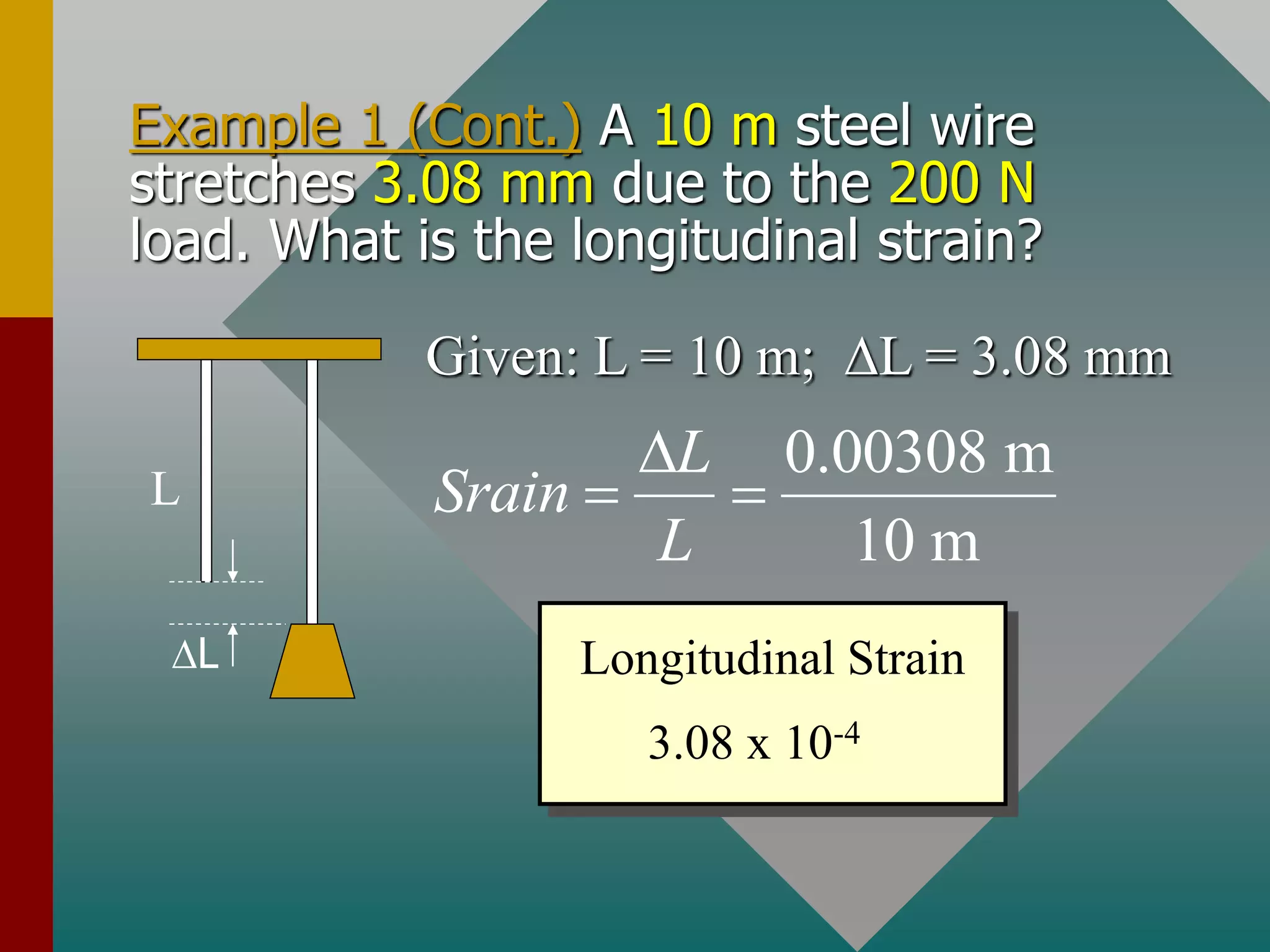

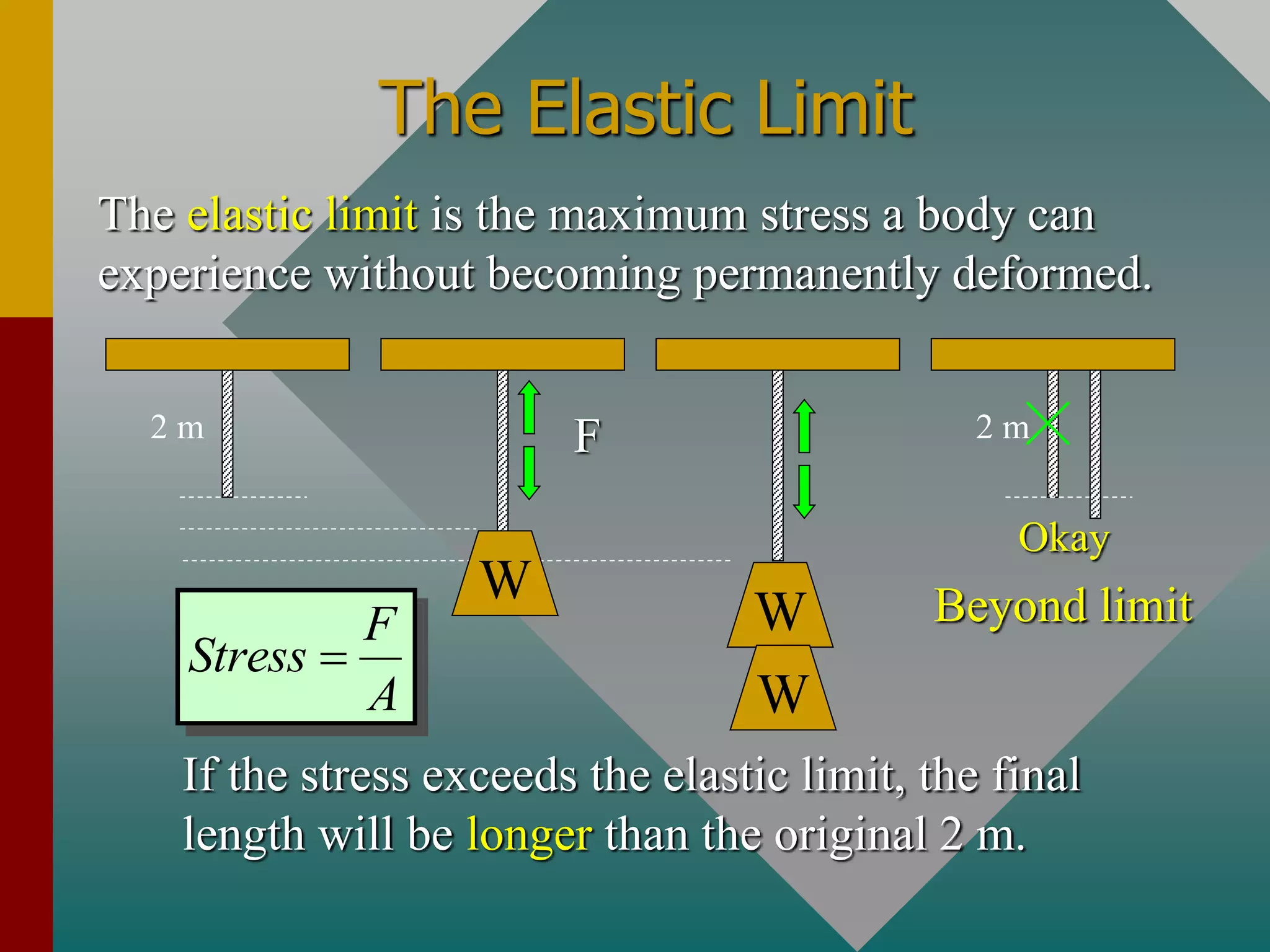

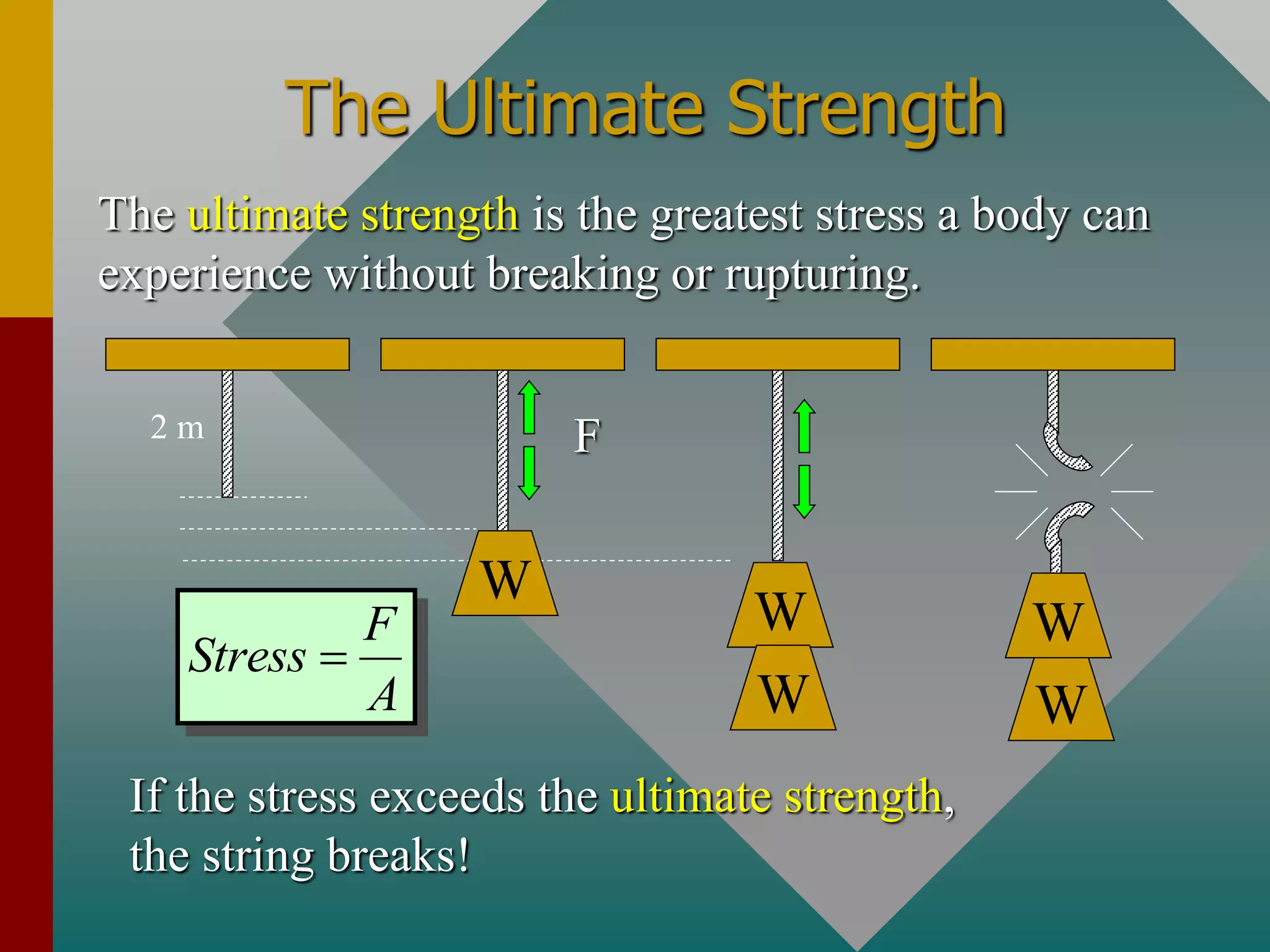

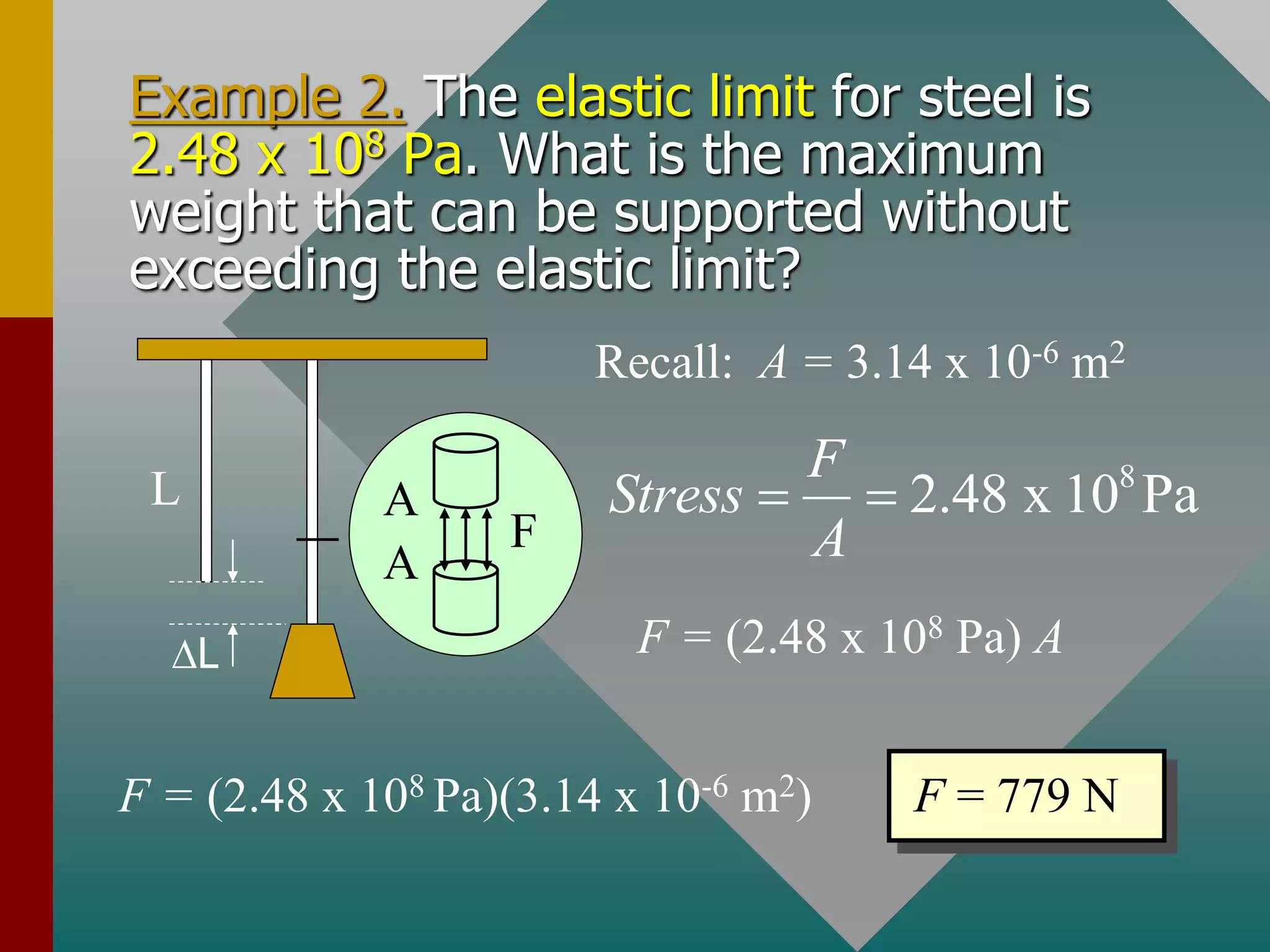

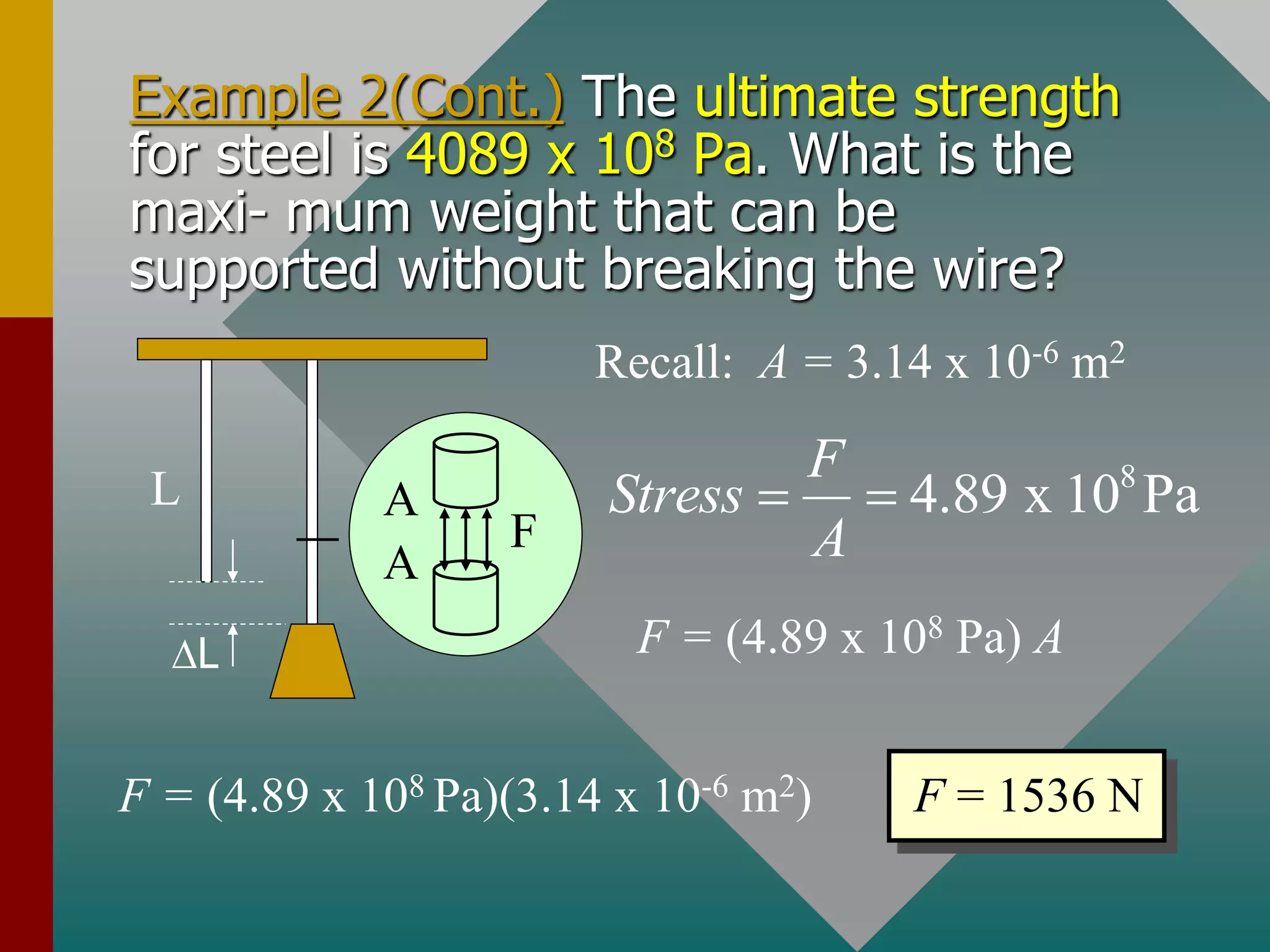

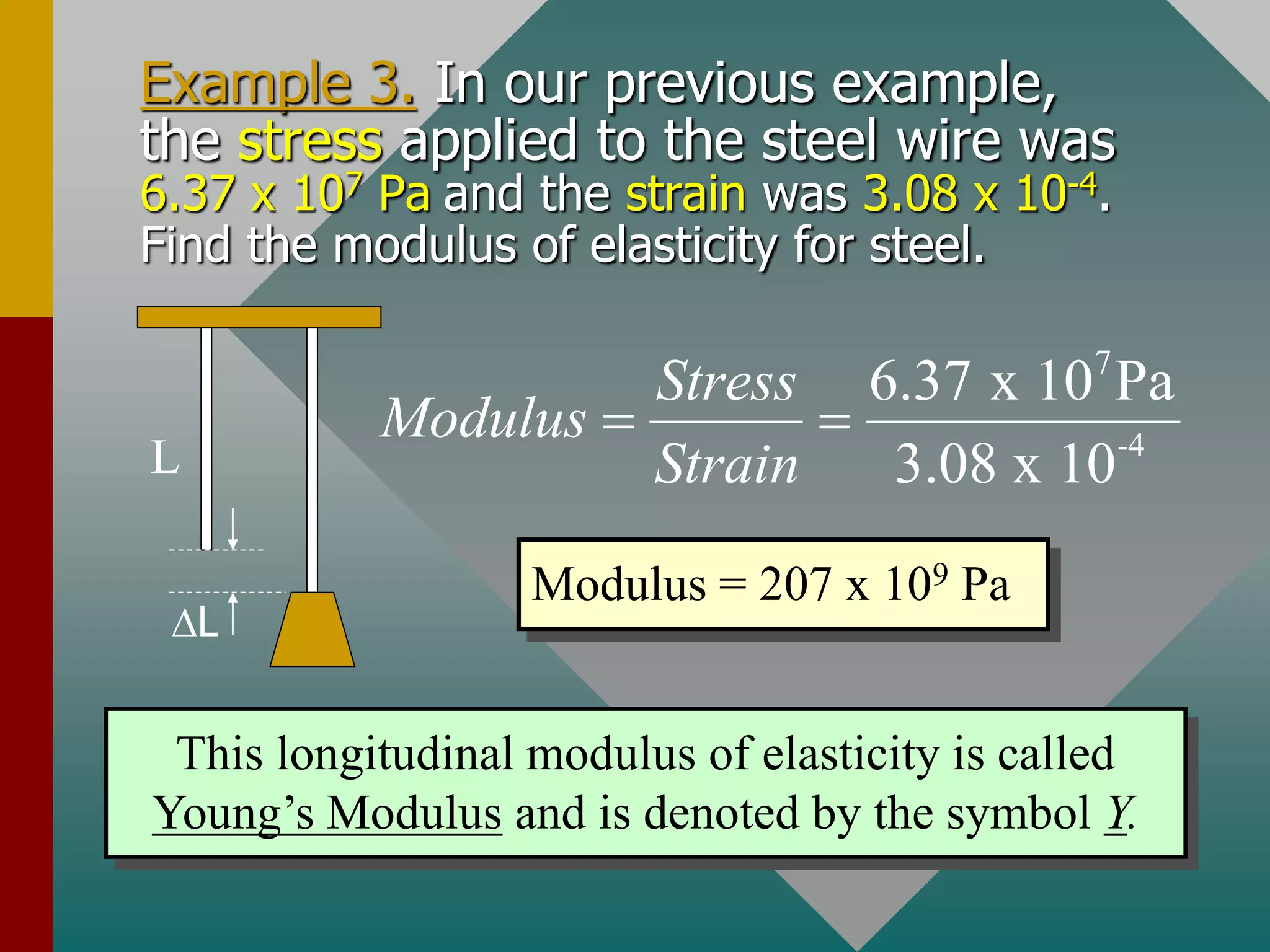

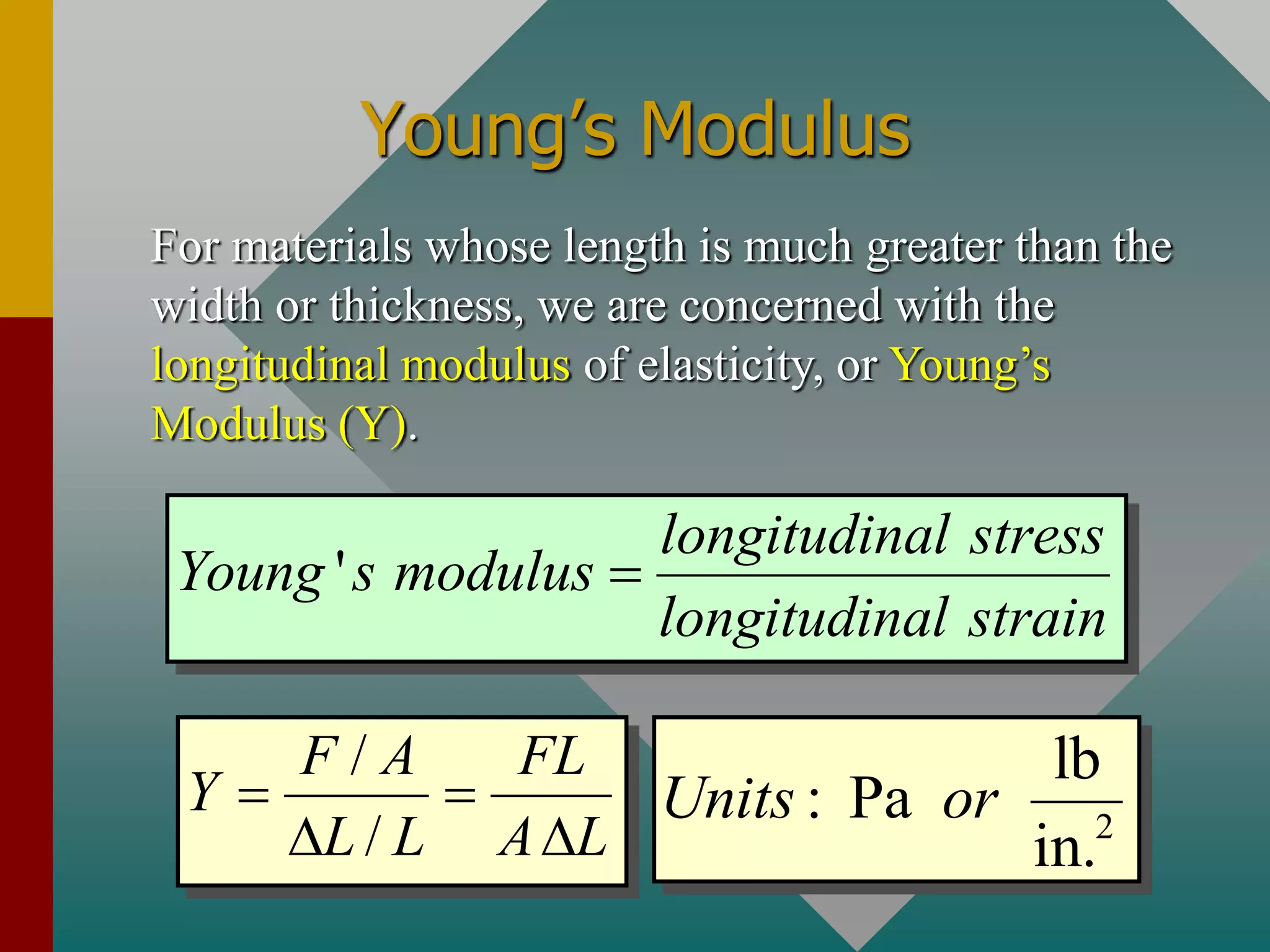

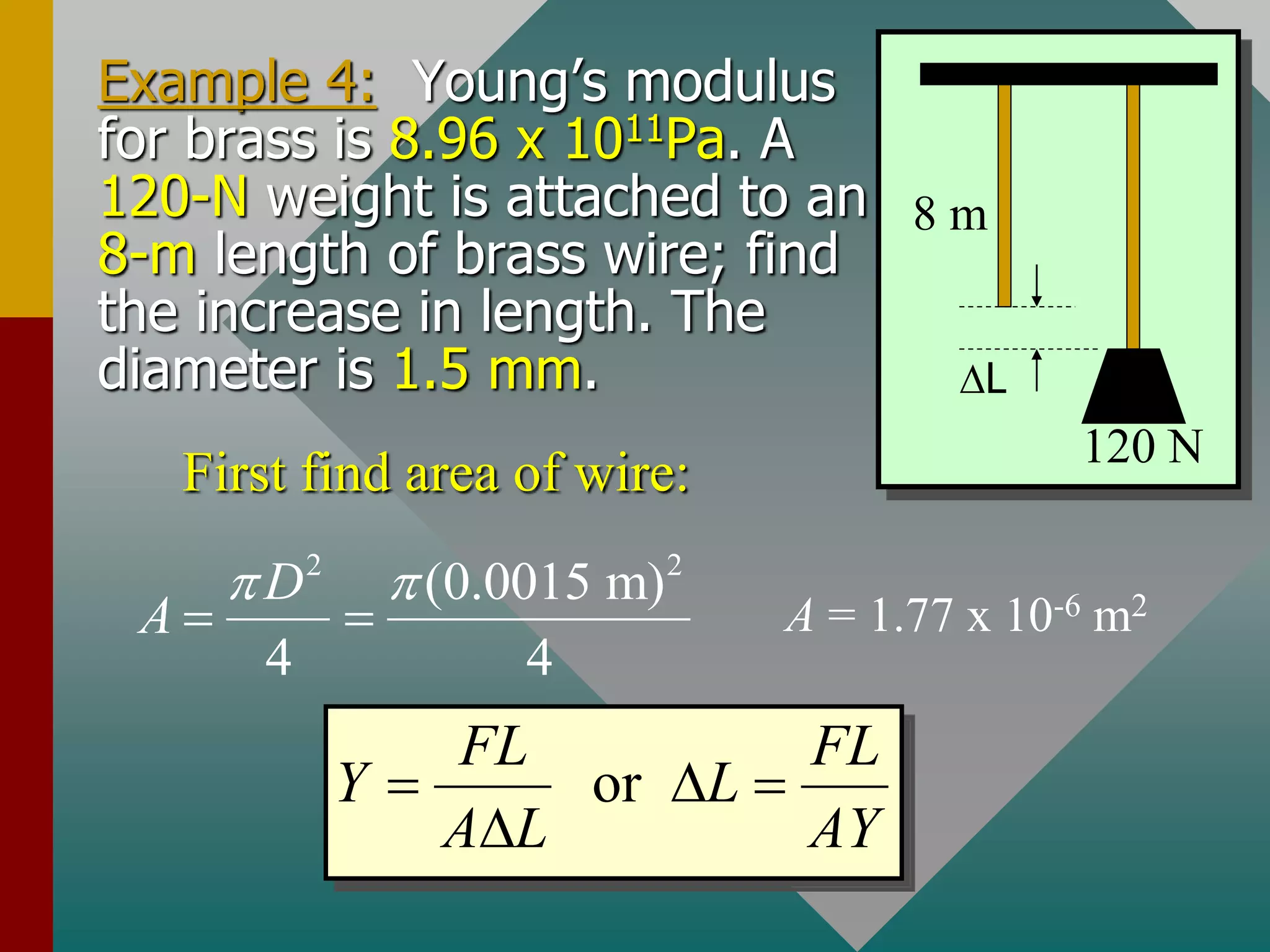

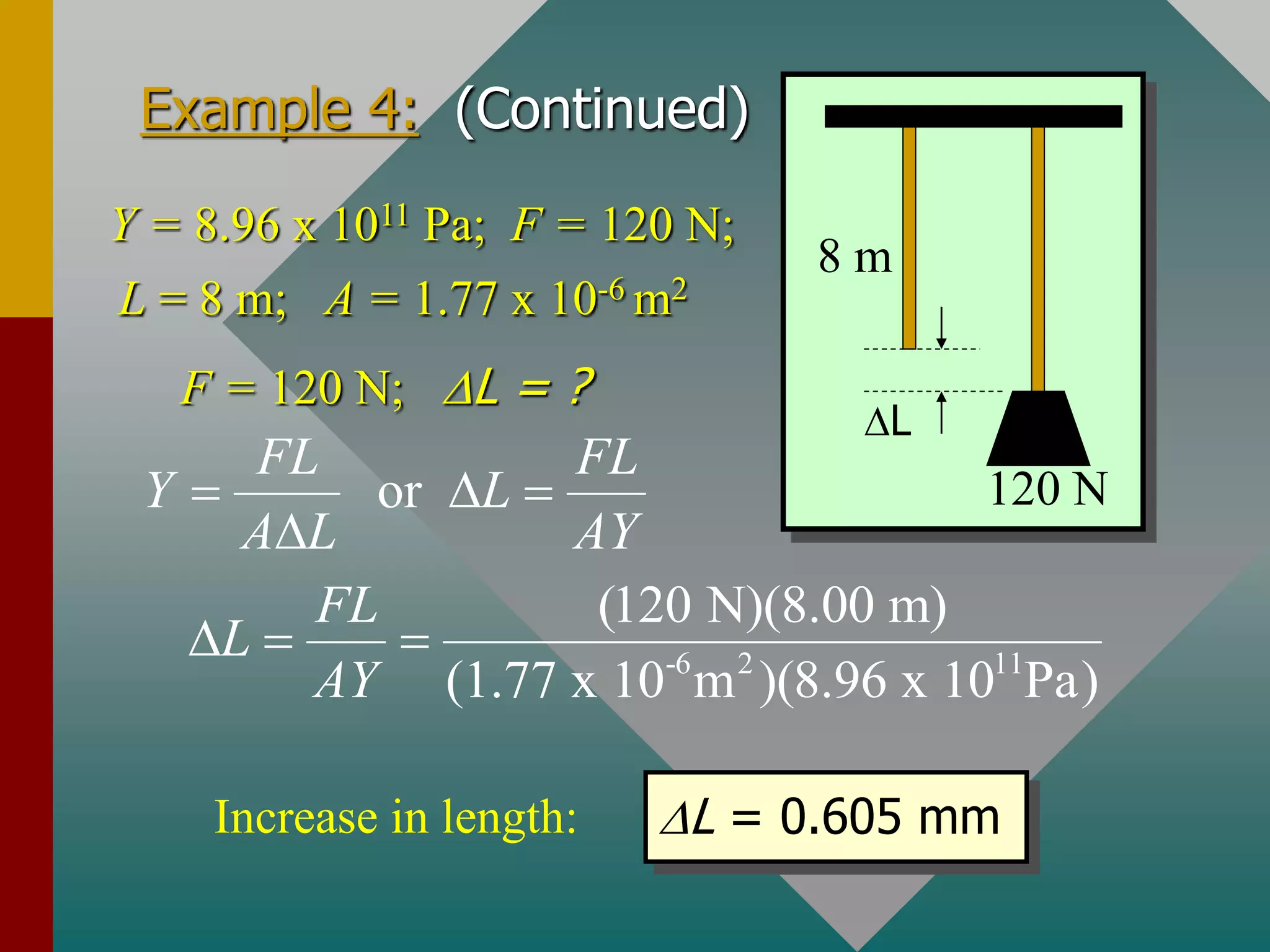

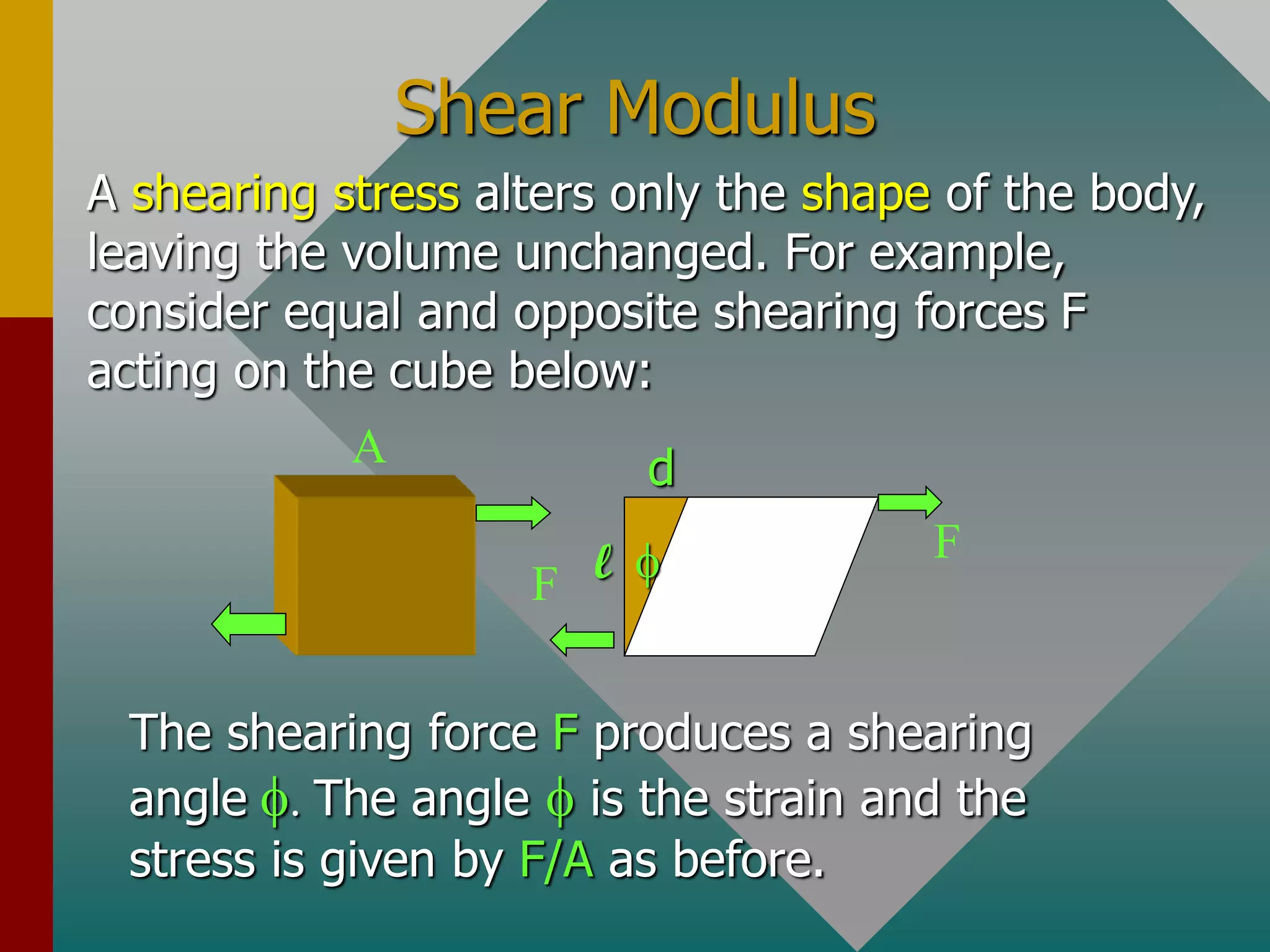

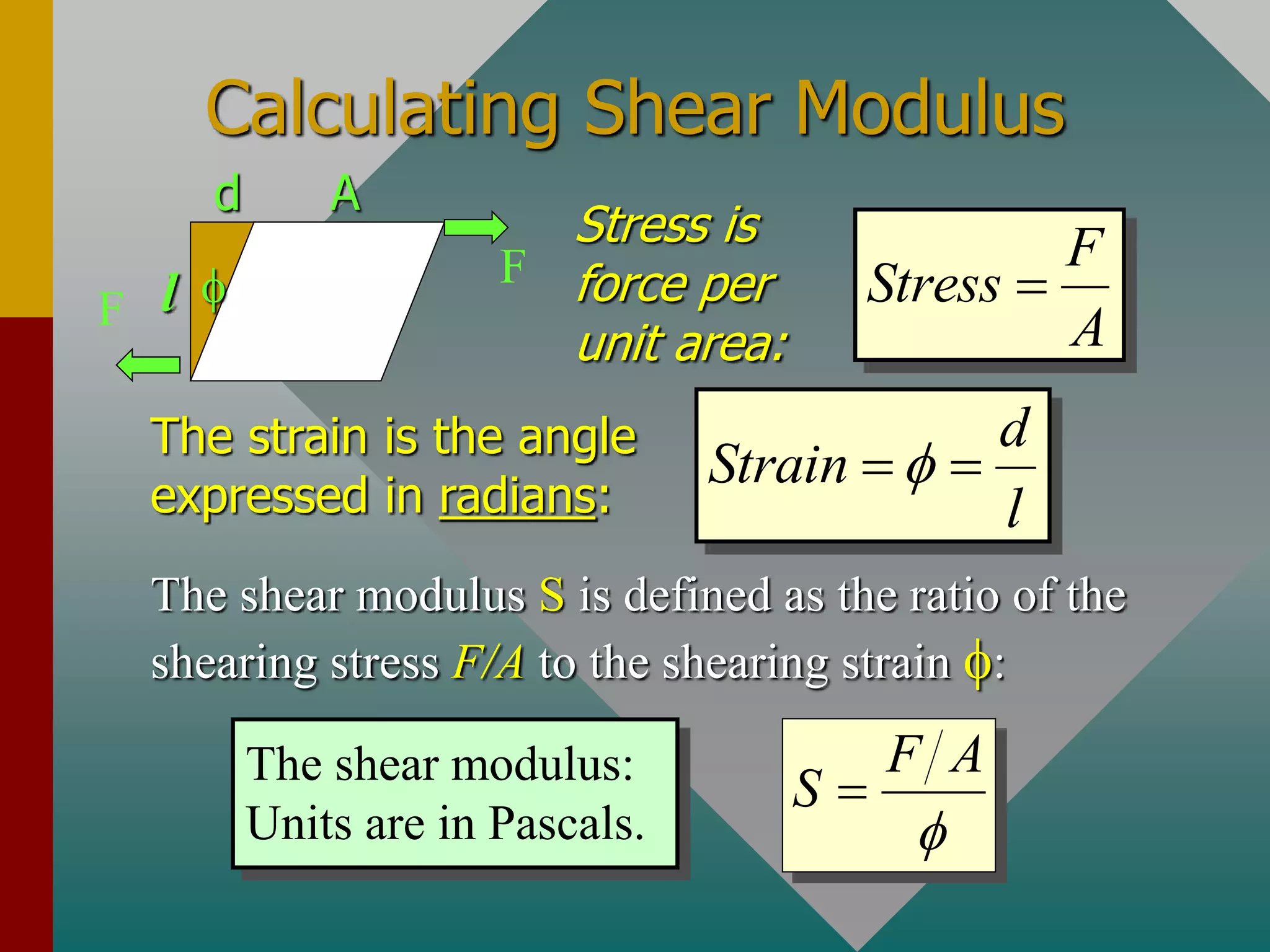

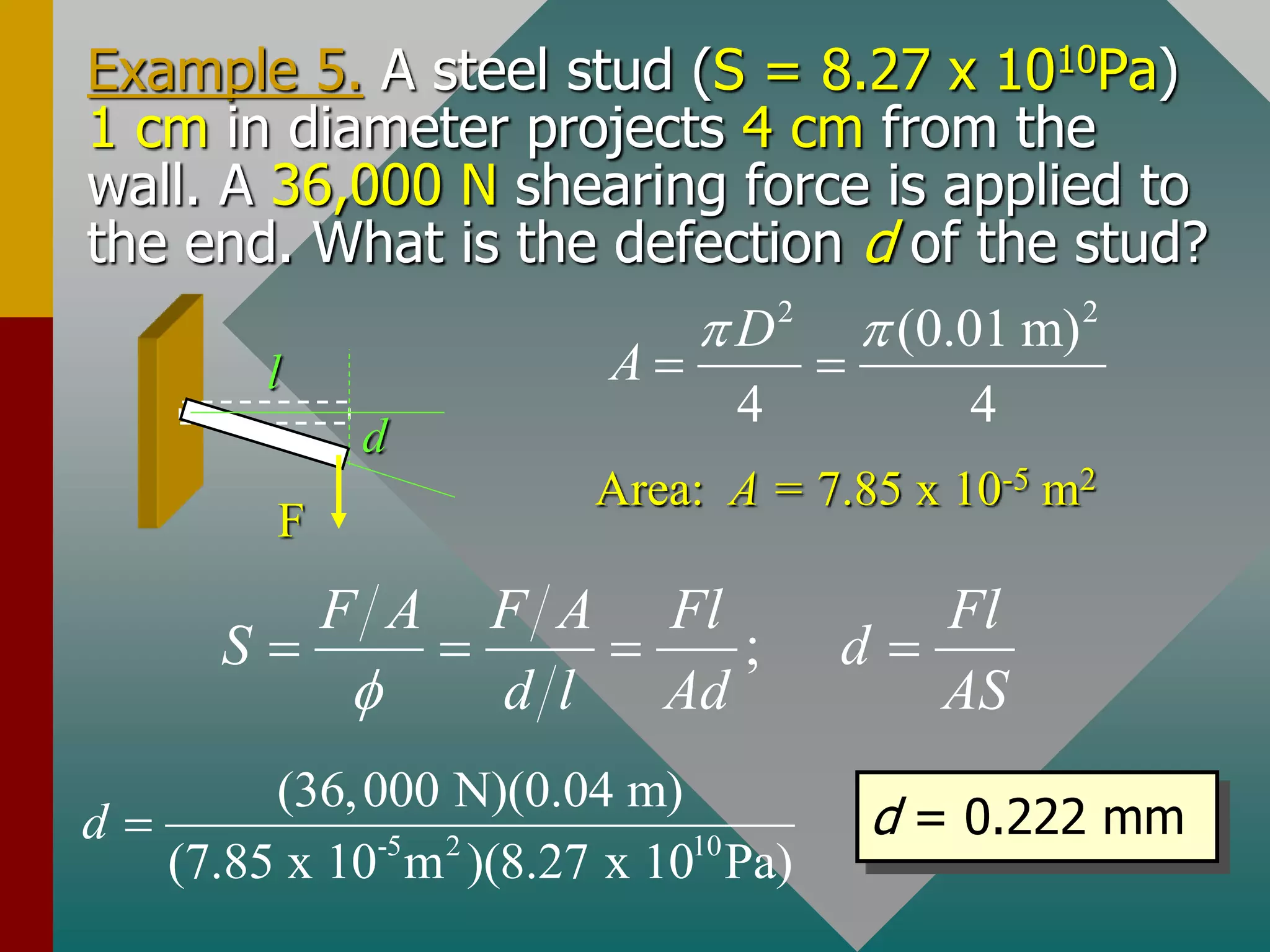

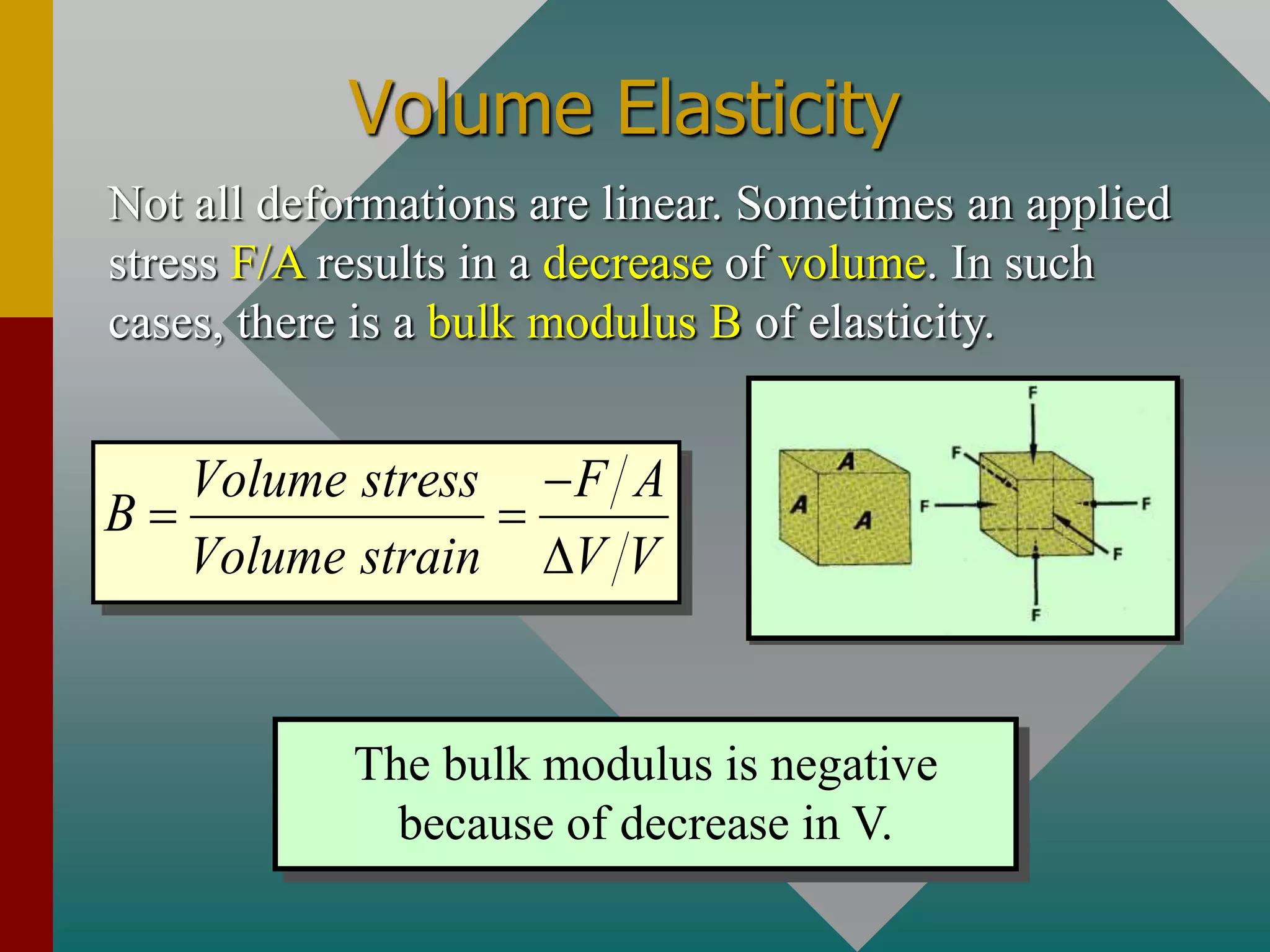

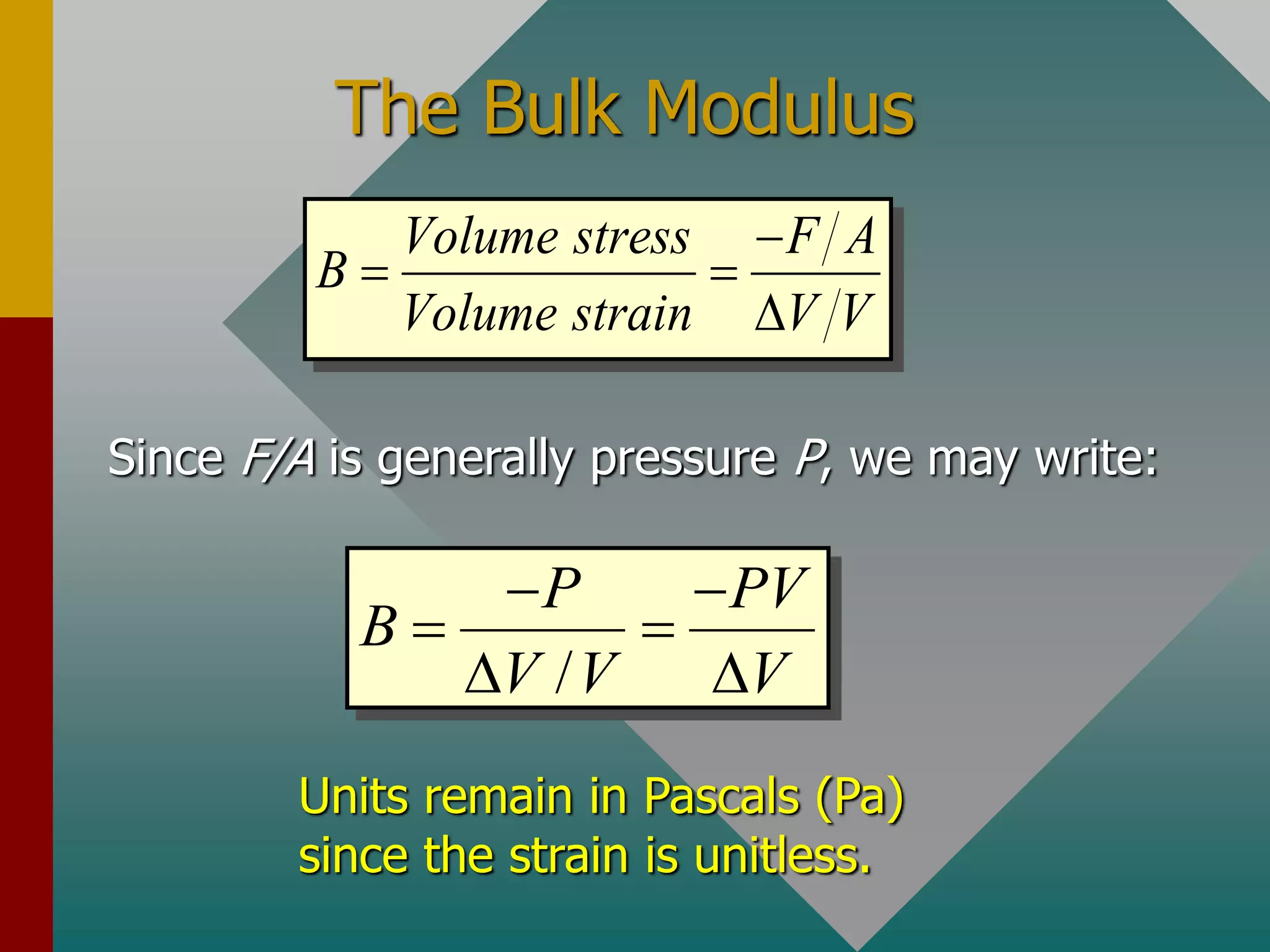

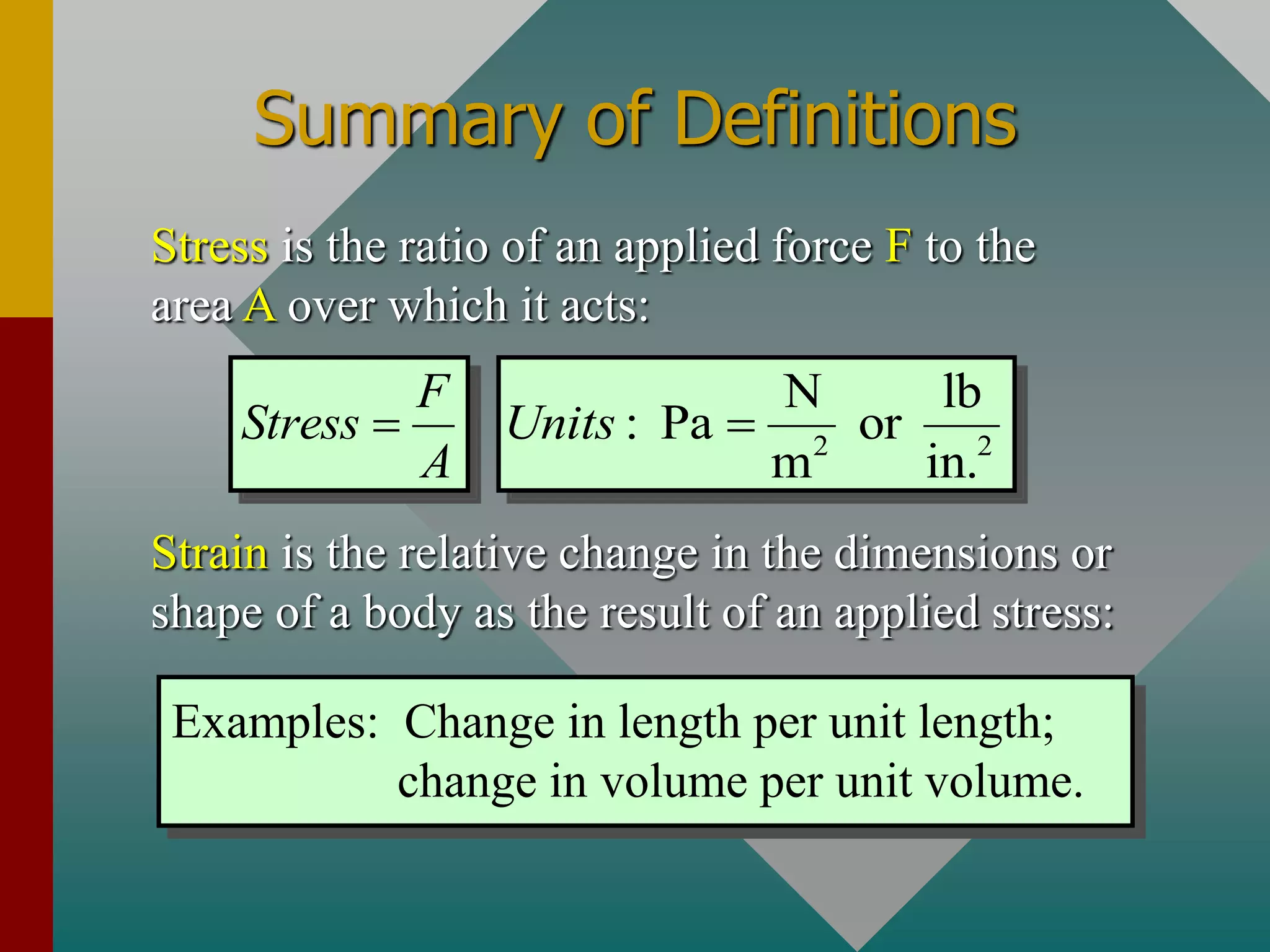

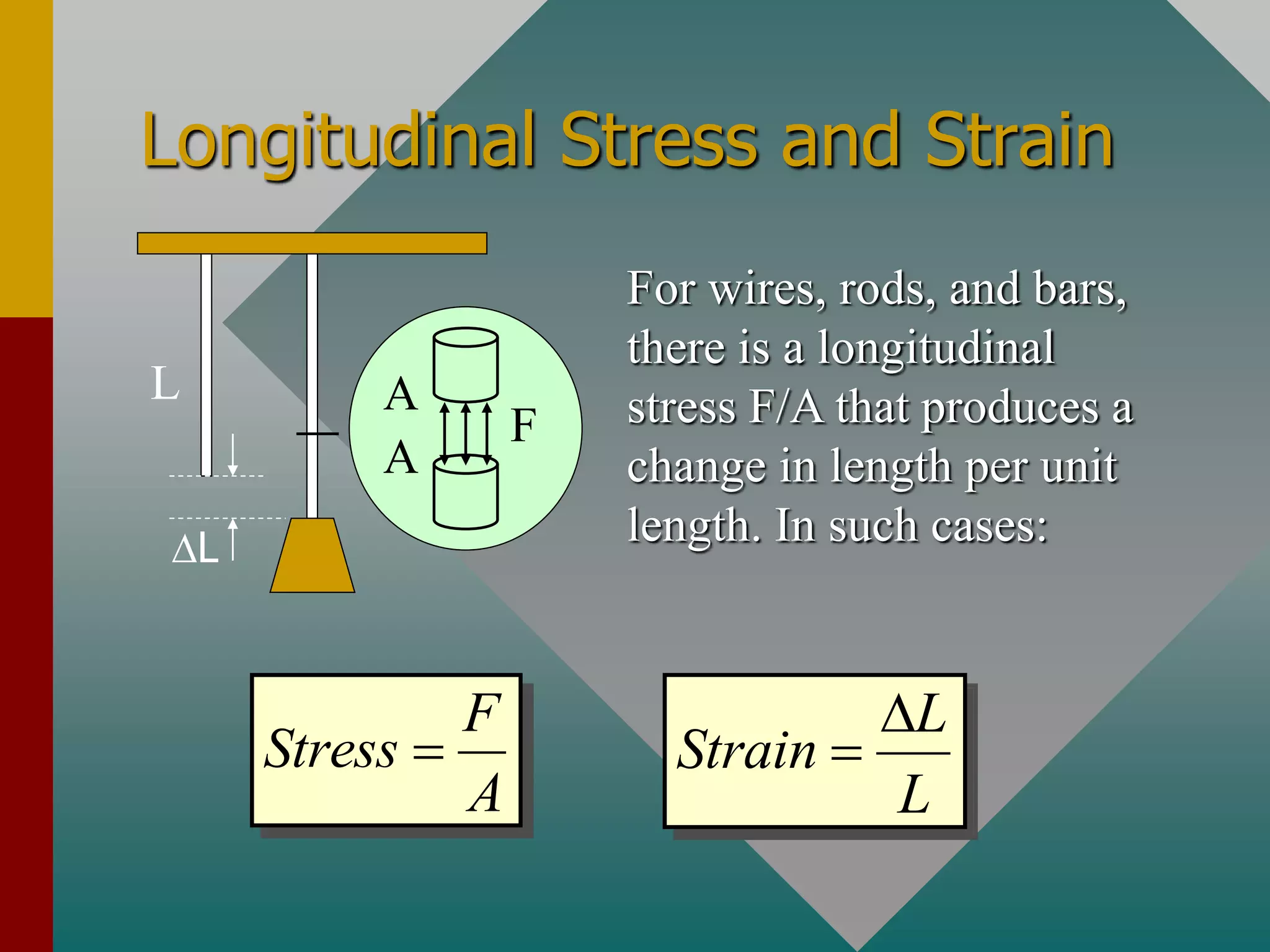

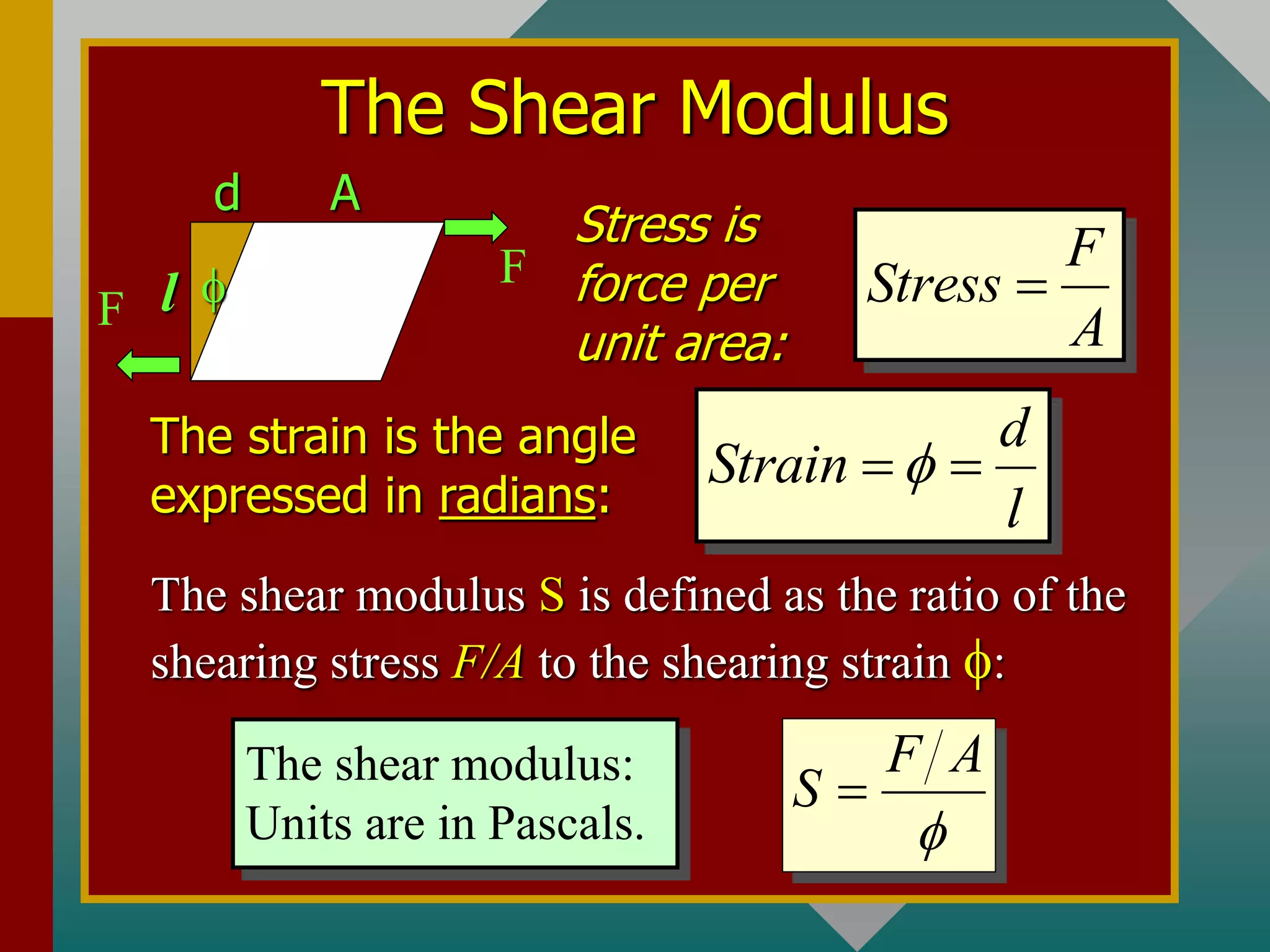

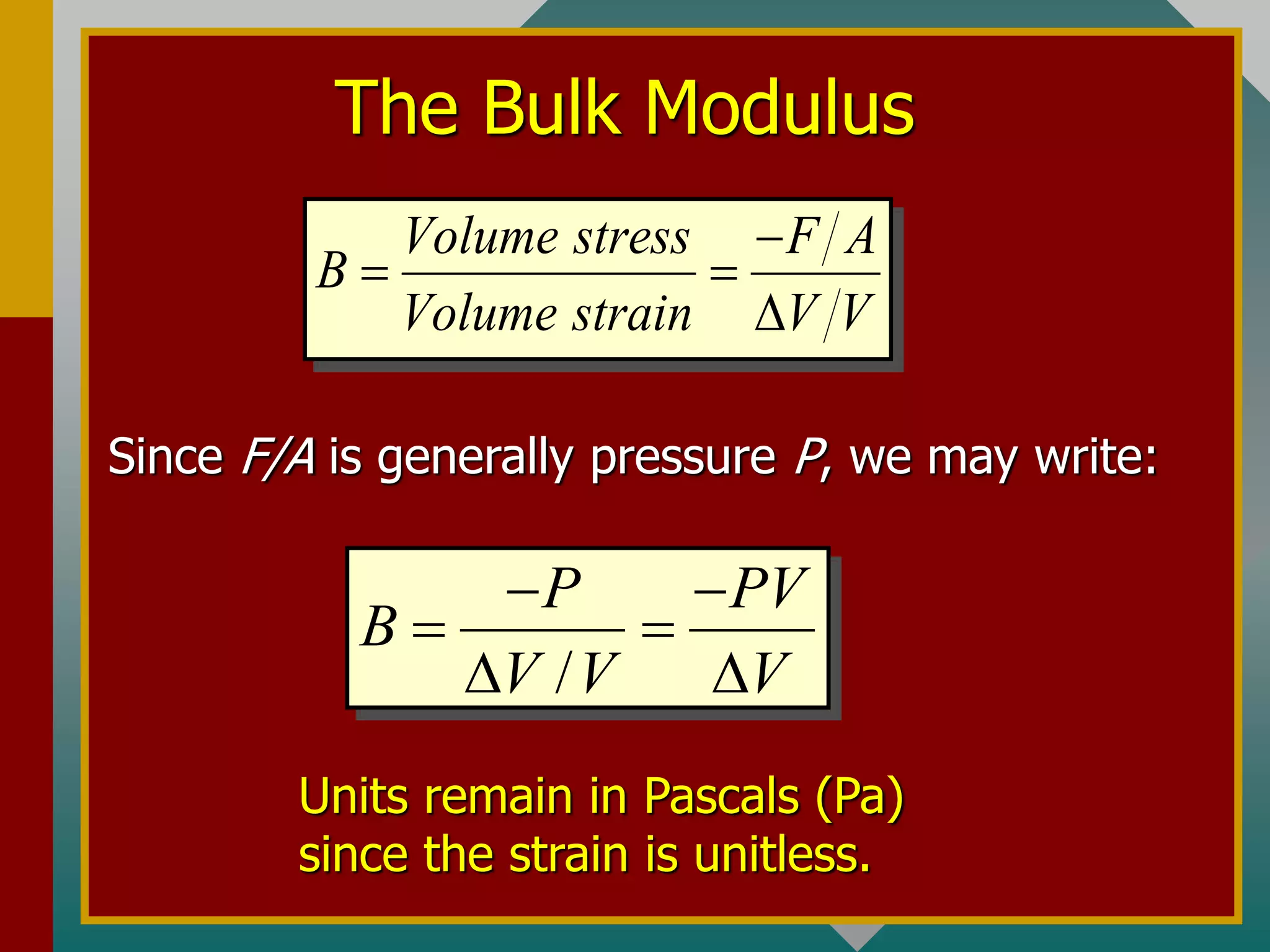

The document discusses the principles of elasticity, detailing the concepts of stress, strain, elastic limit, and ultimate strength. It explains the calculations involved in determining Young's modulus, shear modulus, and bulk modulus, as well as providing examples to illustrate these principles. It also differentiates between elastic and inelastic bodies, describing how they respond to forces and deformations.