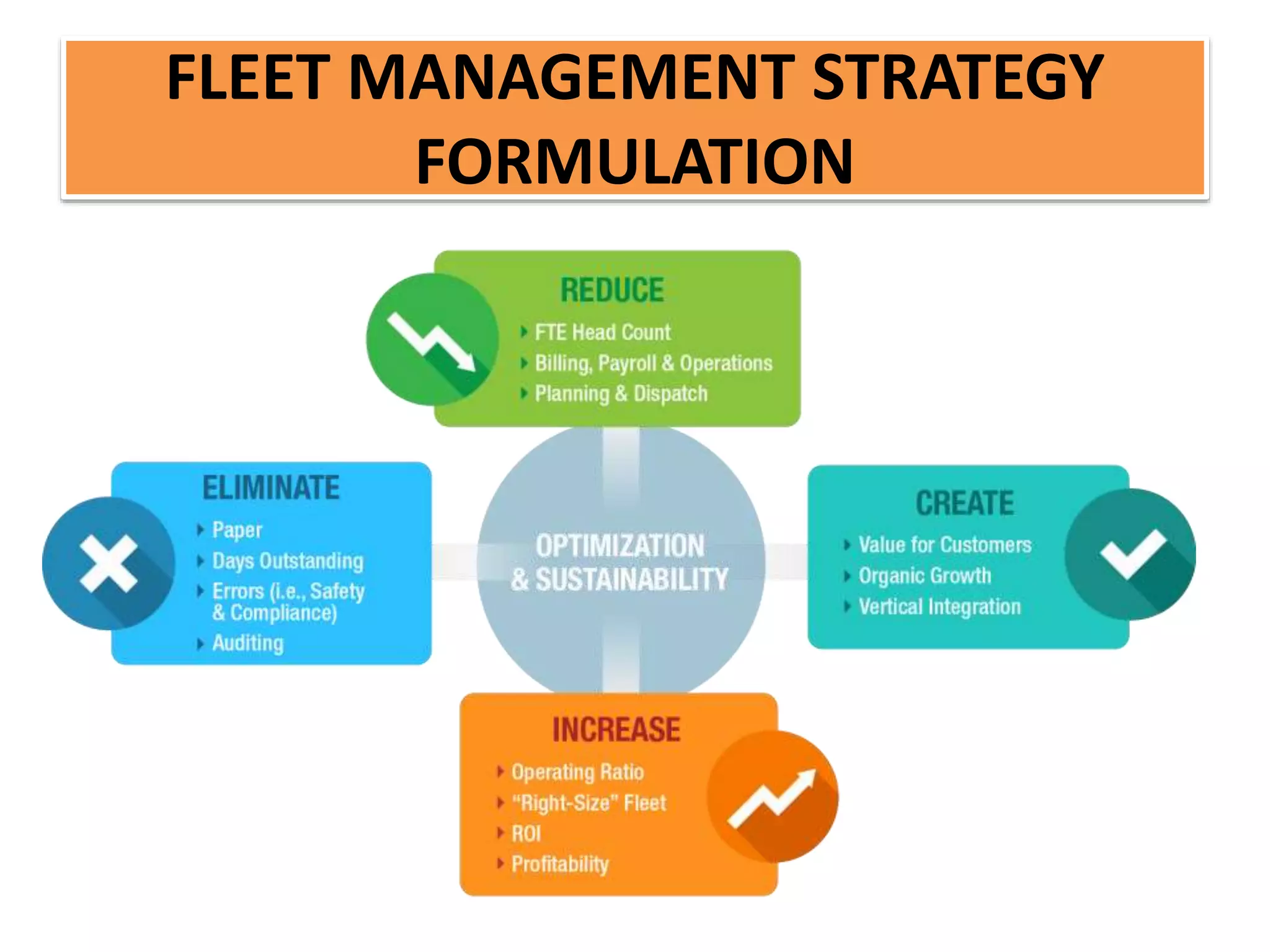

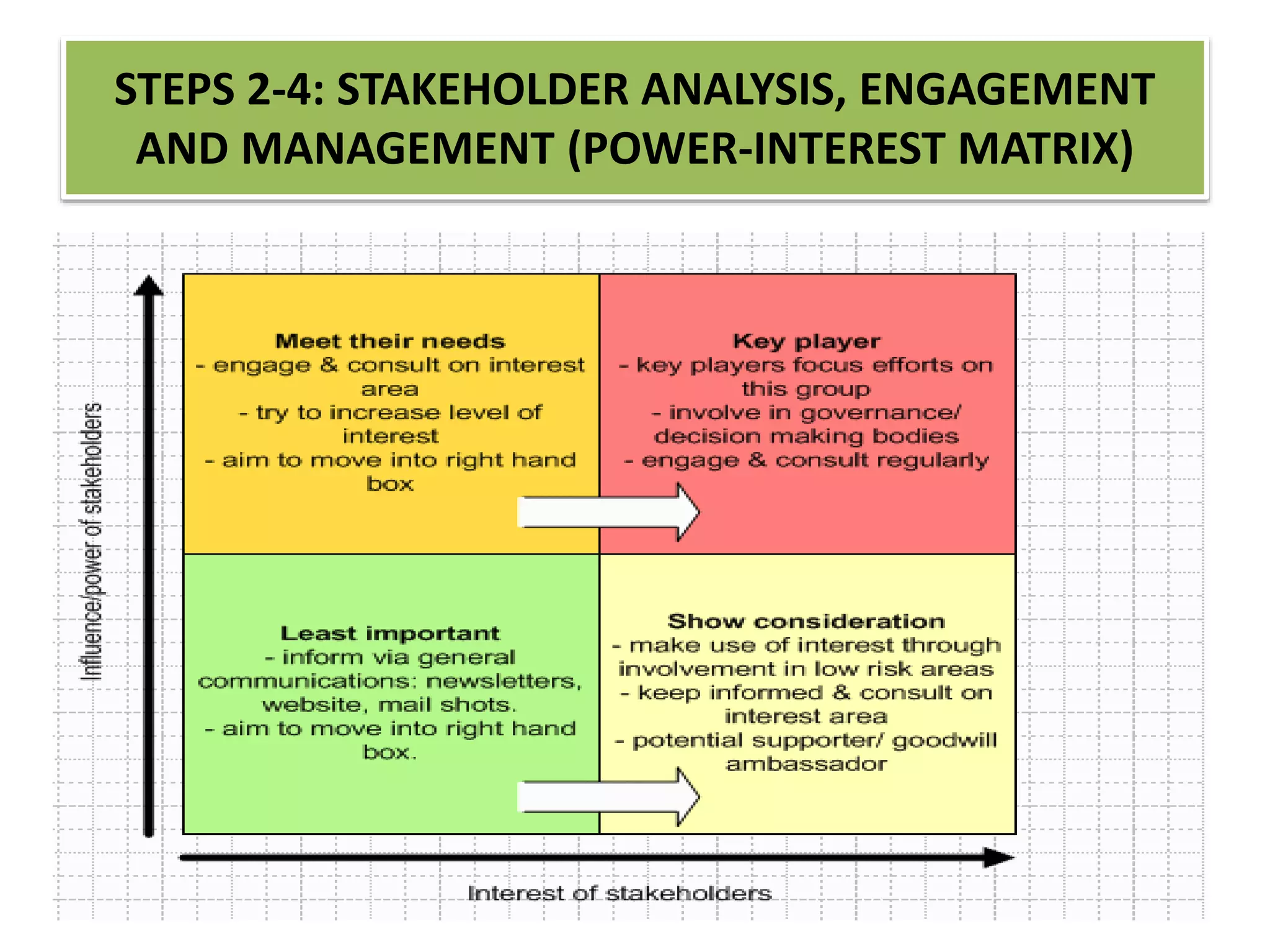

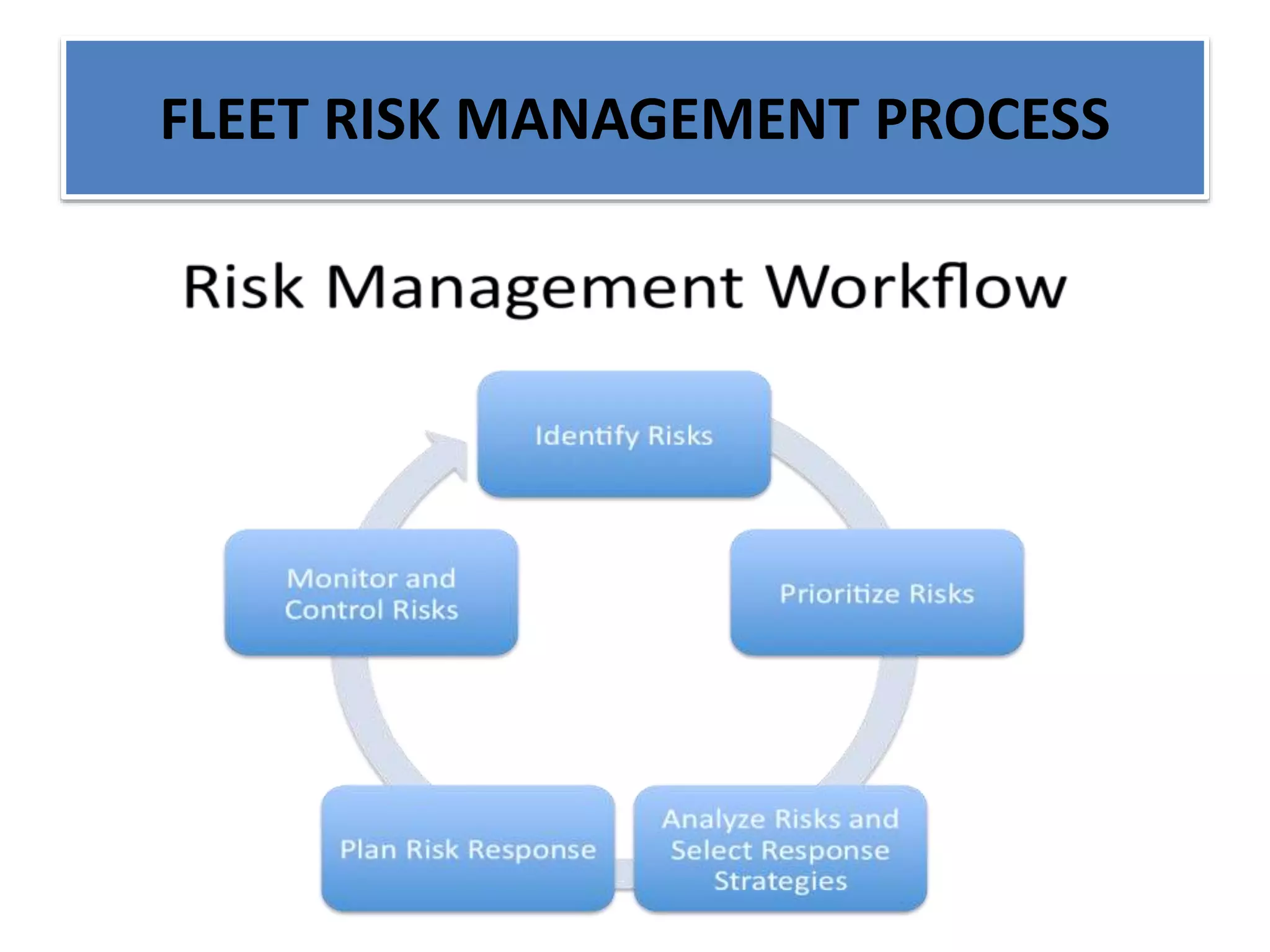

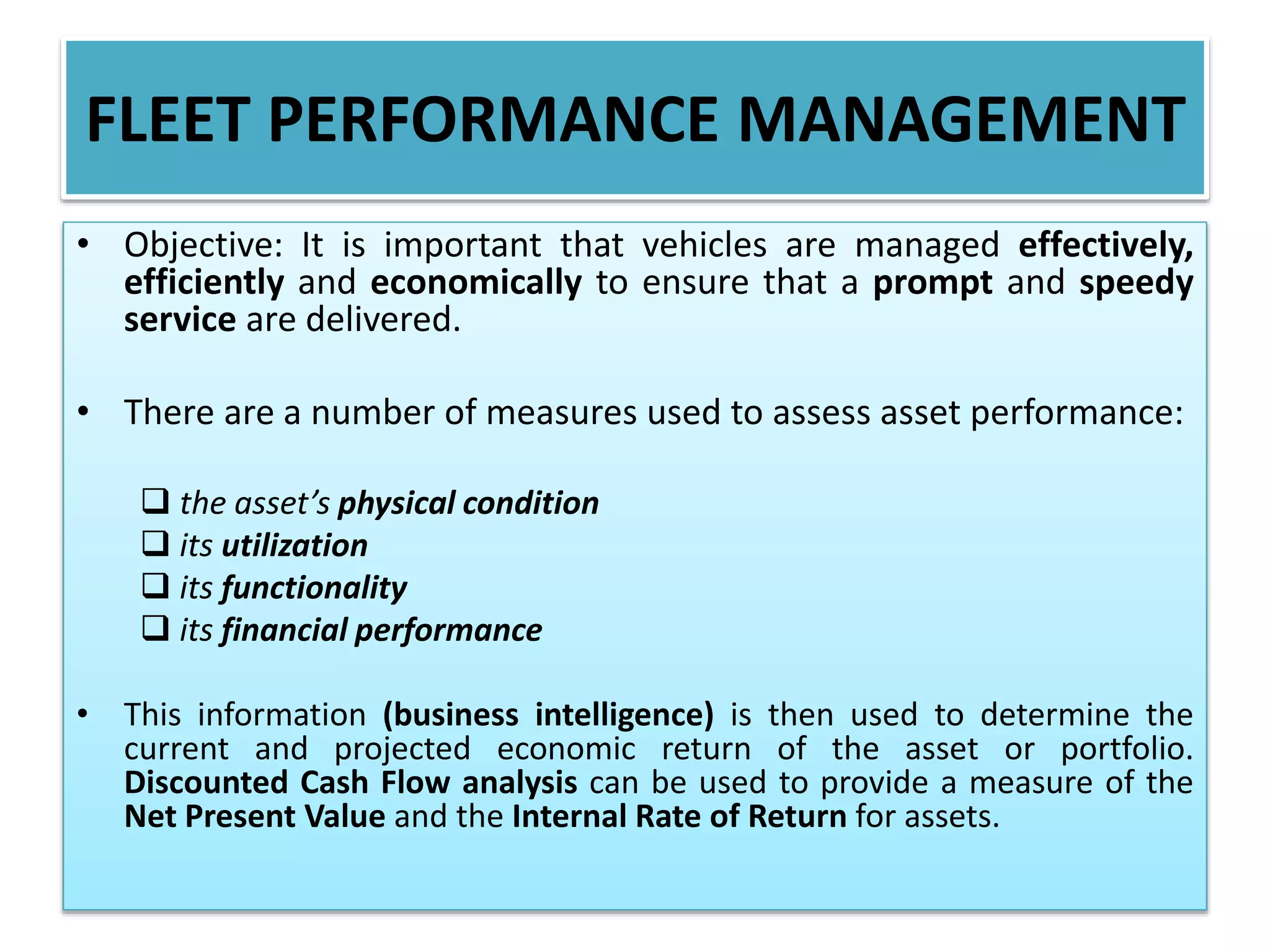

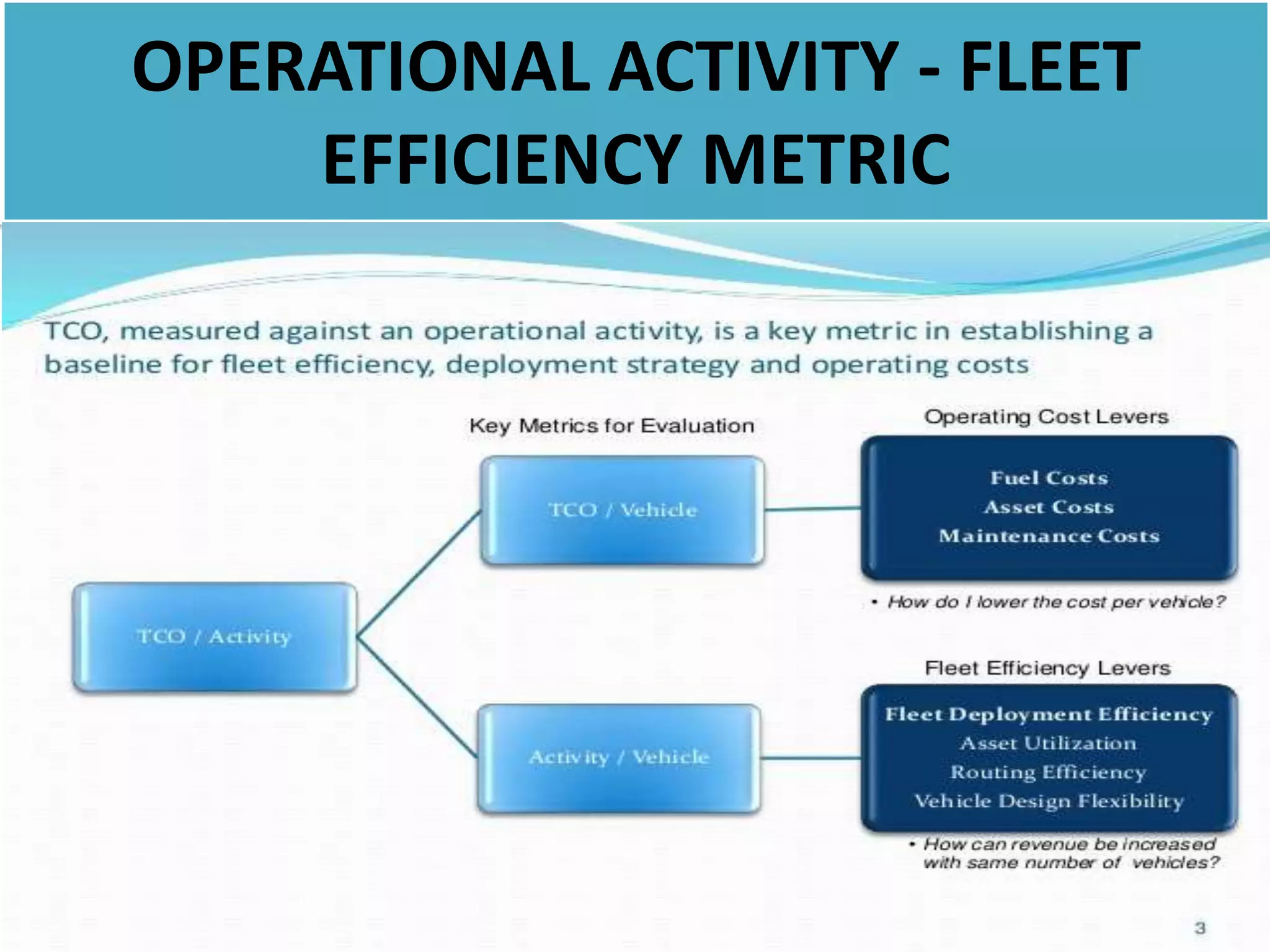

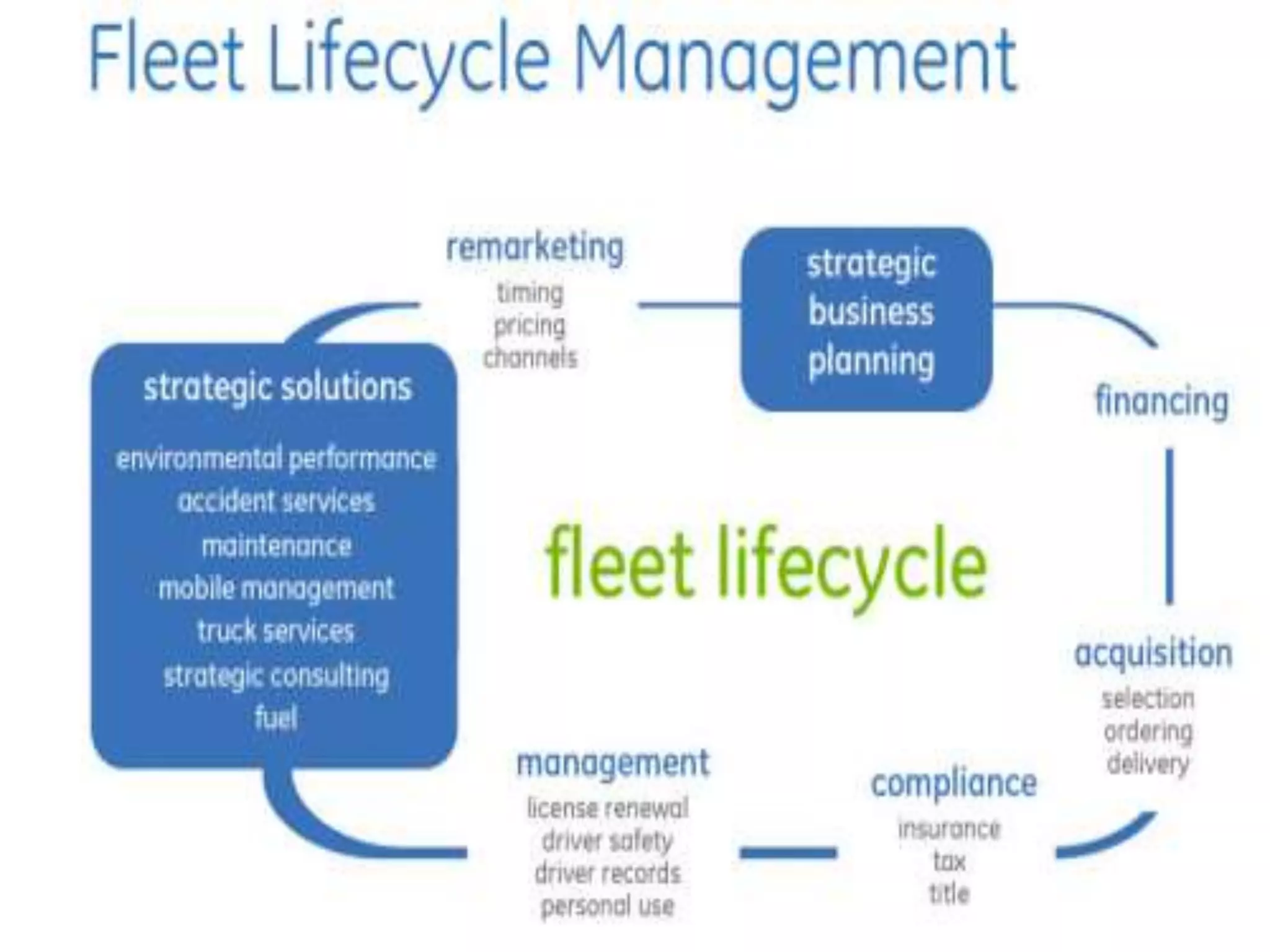

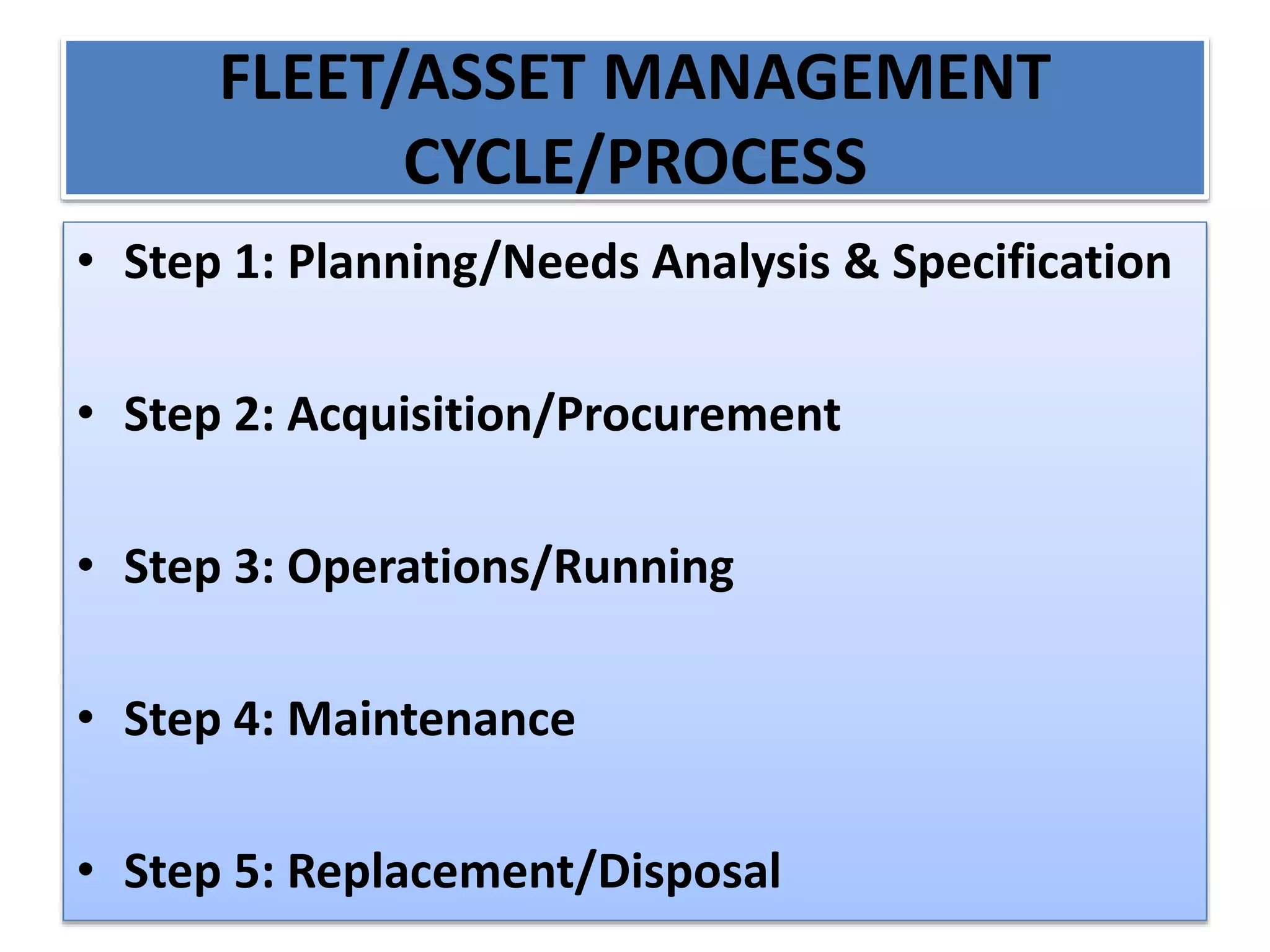

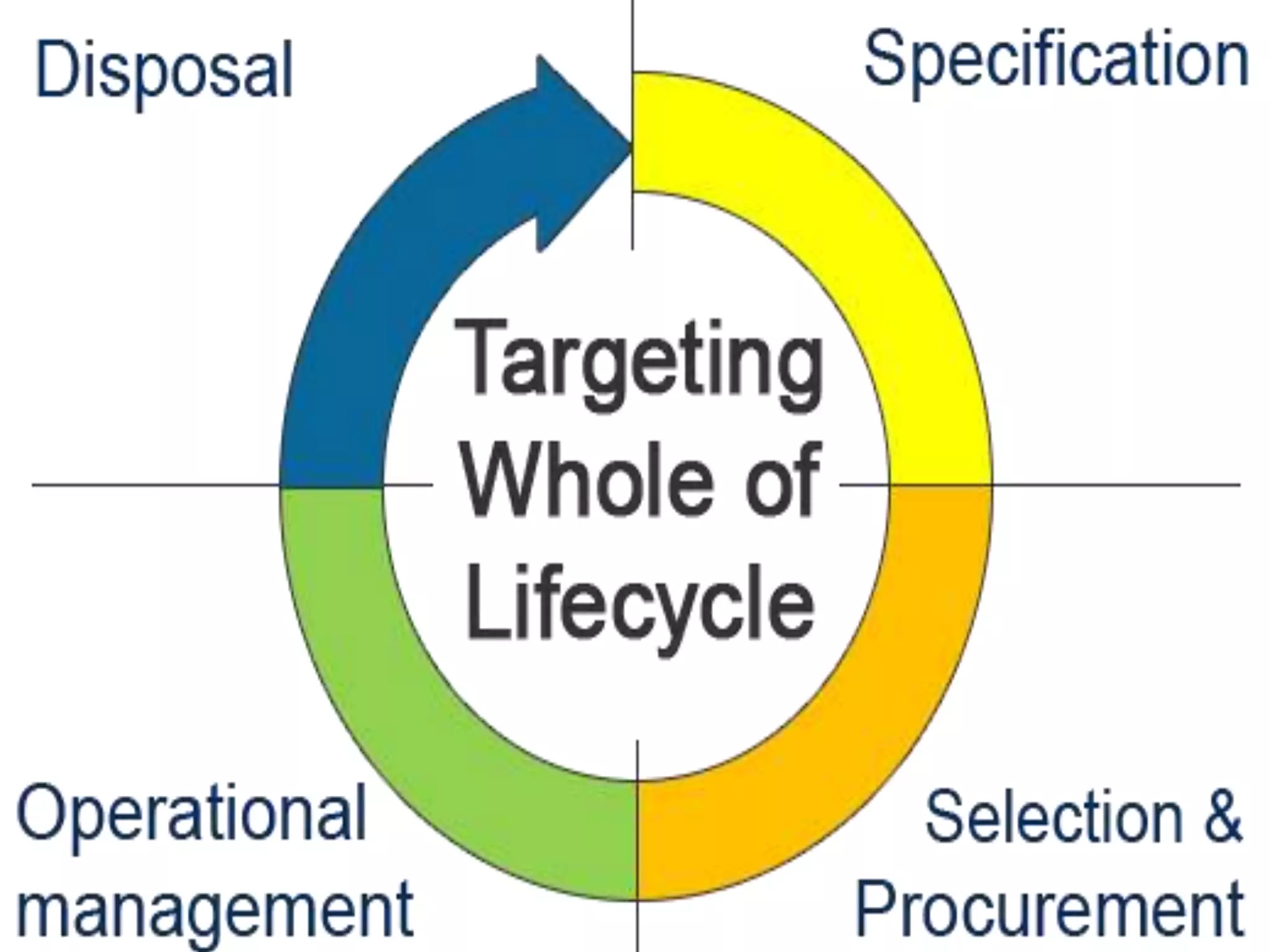

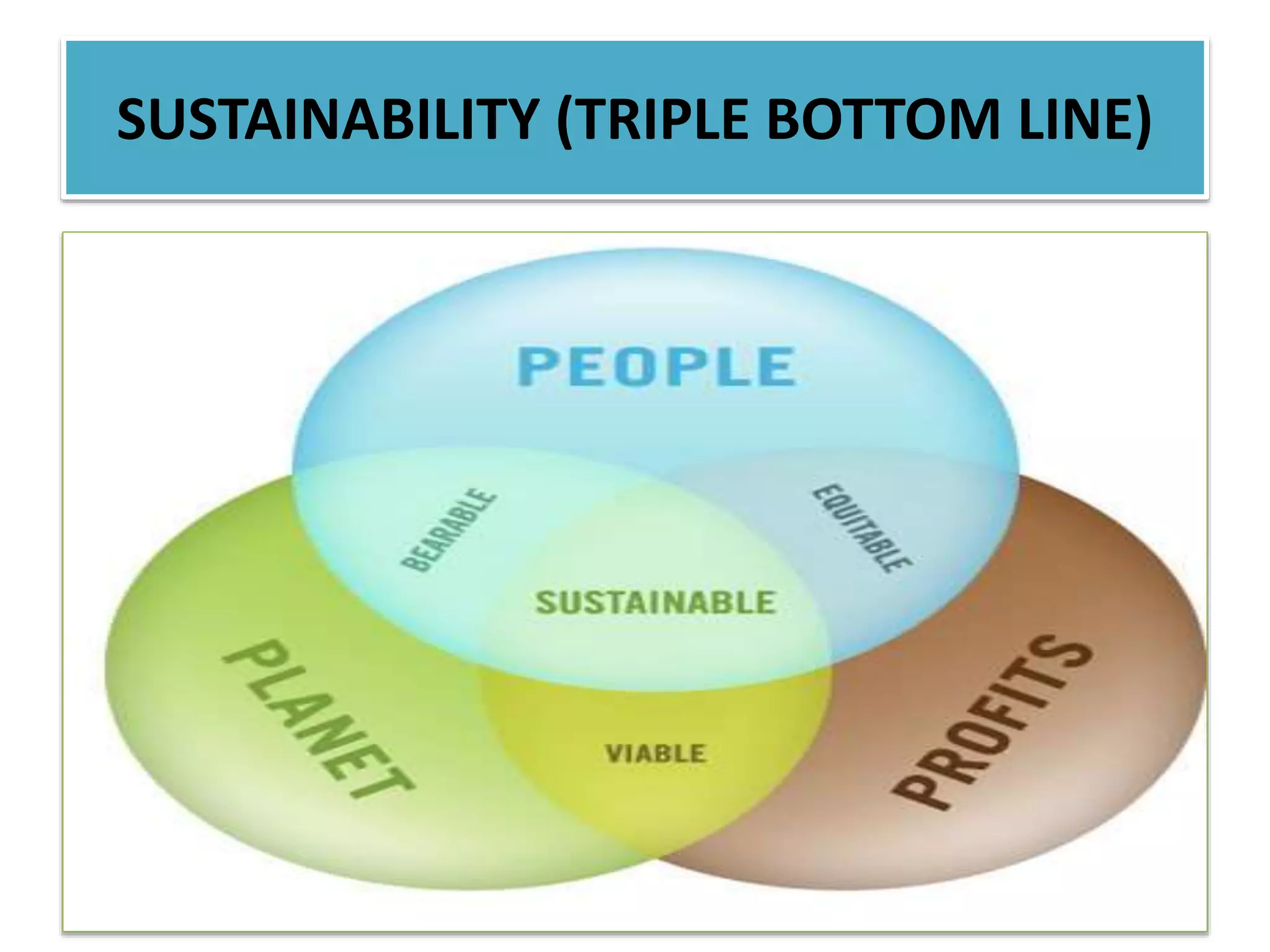

This document outlines a training programme on strategic fleet and transport management. It covers defining concepts, principles of strategic fleet management, stakeholder analysis, risk management, internal control, and performance management as they relate to fleet management. It also describes introductory learning activities and the 4-step strategic fleet management process. Key topics include relating fleet management to organizational strategy and objectives, objectives of strategic fleet management, analyzing the business environment, formulating a fleet management strategy, and optimizing fleet performance through metrics and management. Learning activities involve applying concepts like SWOT analysis, the strategic management process, stakeholder analysis, risk management, and performance indicators to organizational fleet practices.