The document discusses several water and waste water management solutions from James Fisher Tank Inspection including:

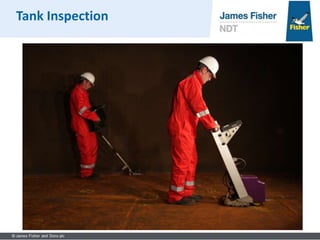

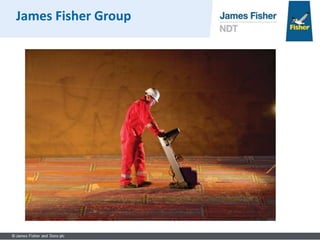

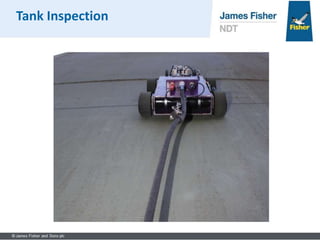

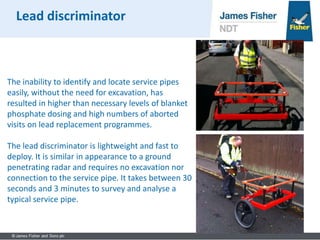

1) A lead discriminator that can identify and locate service pipes without excavation in 30 seconds to 3 minutes.

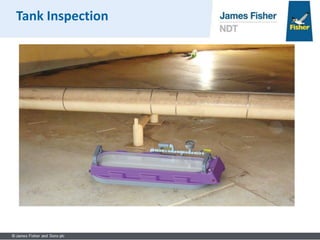

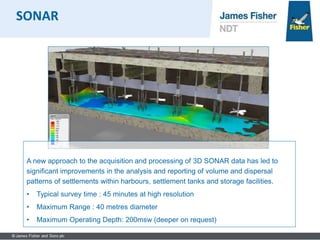

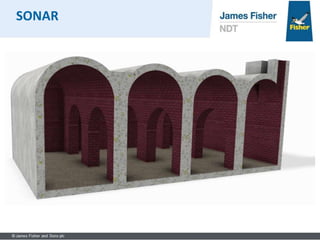

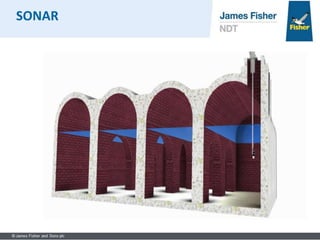

2) 3D SONAR technology that can map settlements in harbors, tanks, and storage facilities with a survey time of 45 minutes and a maximum range and depth of 40 meters and 200 meters respectively.

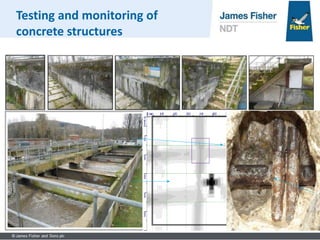

3) Techniques for in-situ stress measurement in concrete and steel reinforcement to test and monitor concrete structures.