The document discusses standards and guidelines for maintaining sterile environments and compounding sterile products, including:

- USP Chapter 797 which covers equipment, techniques, and quality control for sterile products to prevent harm from microbial contamination or incorrect ingredients.

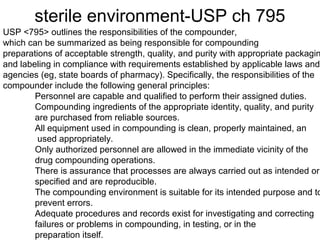

- USP Chapter 795 which outlines the responsibilities of compounders to produce safe, high quality medications.

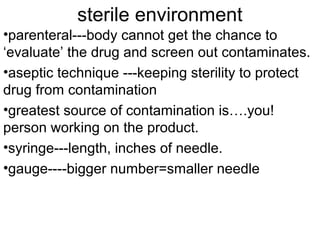

- Maintaining clean rooms, anterooms, and laminar flow hoods at ISO particle standards to control contamination, with the most stringent standard of ISO Class 5 required for laminar flow hoods.

- Proper attire, cleaning procedures, and environmental controls are needed to ensure work areas are sufficiently sterile for compounding sterile products.