This document discusses the design and operation of an aseptic area for producing sterile pharmaceutical products. It is divided into several sections:

1) The aseptic area requires strict control measures to avoid contamination, including stainless steel surfaces that do not accumulate dirt and separate mixing/storage areas. Products are transferred via pipelines for filling.

2) Adjacent areas include a cleanup section with HEPA-filtered air, a compounding section that controls dust, a quarantine storage area, and a packaging/labeling room.

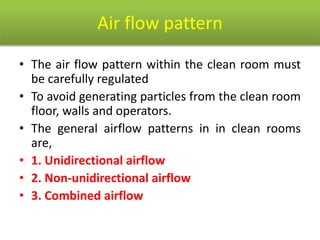

3) Contamination can originate from the atmosphere, fluids, or personnel/equipment and is prevented through measures like filtered air, purified water, and sterile protective clothing for operators. Proper airflow