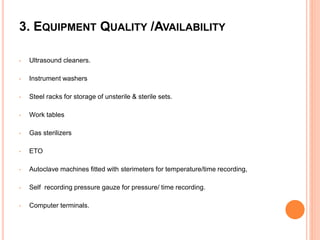

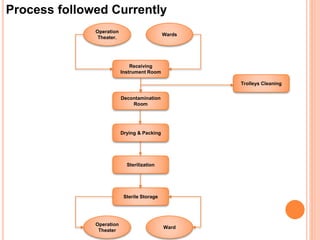

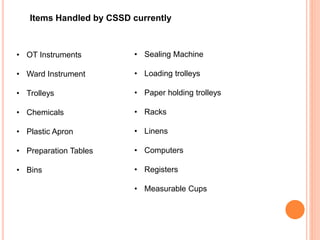

The document provides a comprehensive overview of the Central Sterile Supply Department (CSSD) in a quaternary care hospital, outlining its functions such as sterilizing and distributing surgical instruments. It emphasizes the importance of CSSD in infection control and cost reduction, and details various aspects including staffing, quality management, and current operational challenges. A SWOT analysis identifies strengths, weaknesses, opportunities, and threats related to CSSD operations.