Embed presentation

Downloaded 71 times

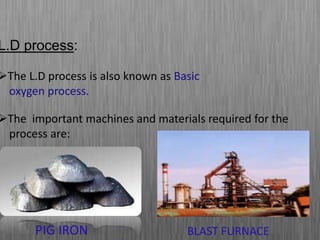

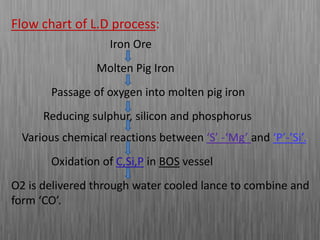

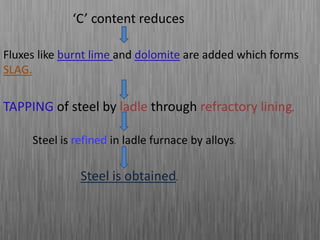

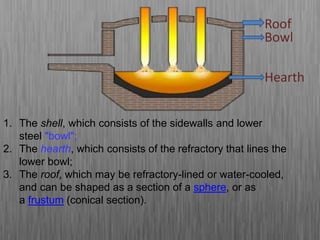

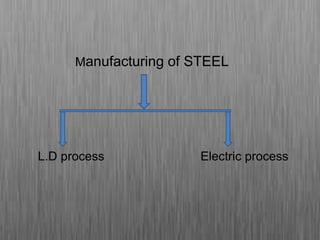

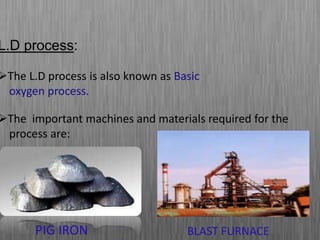

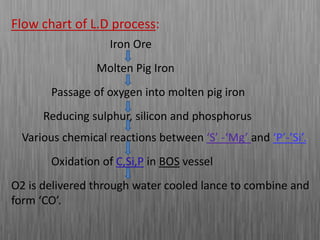

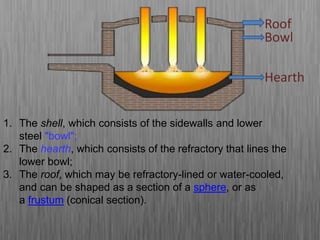

Steel can be manufactured through two main processes: 1) The L.D process (Basic Oxygen Process) involves blowing oxygen through a lance into molten pig iron to reduce the carbon and other impurities, separating a slag. Fluxes are added and the molten steel is tapped and refined. 2) The Electric Arc Furnace process uses an electric arc to heat scrap metal, pig iron, and direct reduced iron. It consists of a steel shell, refractory-lined hearth, and water-cooled or refractory-lined roof. This melts the metal and separates the slag.