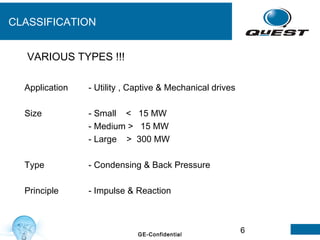

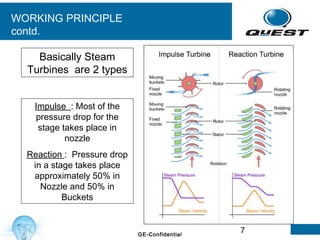

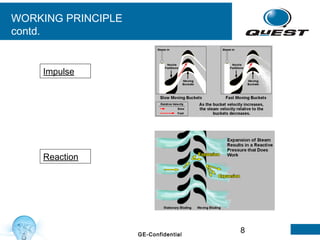

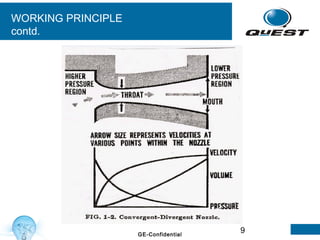

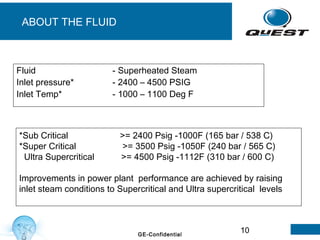

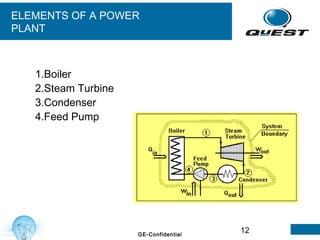

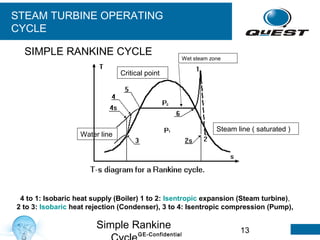

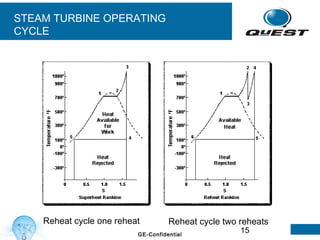

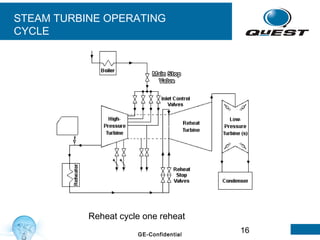

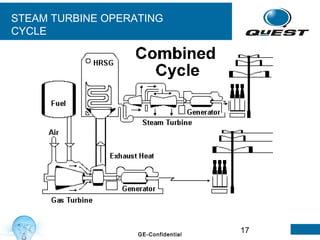

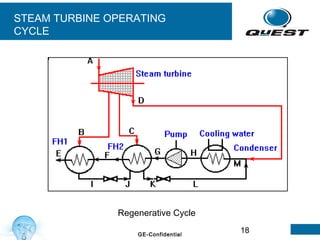

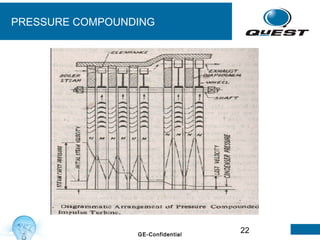

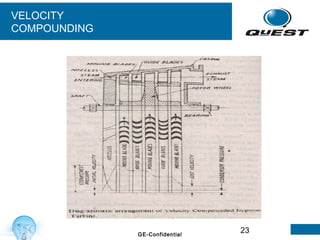

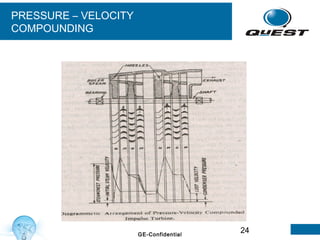

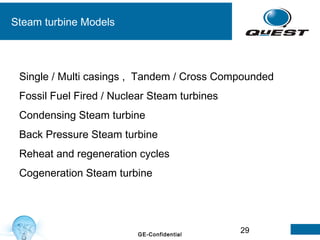

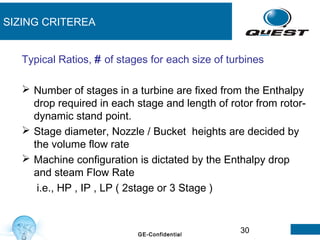

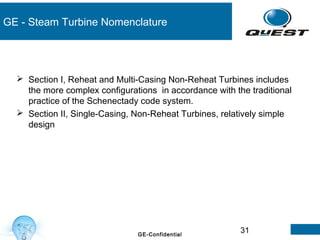

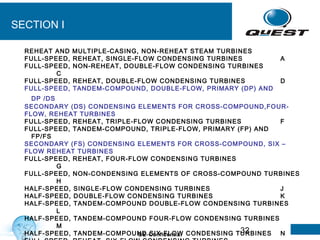

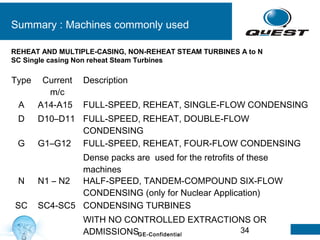

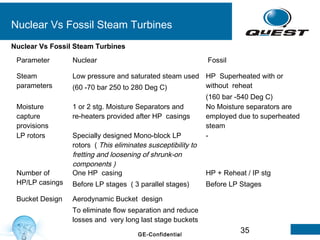

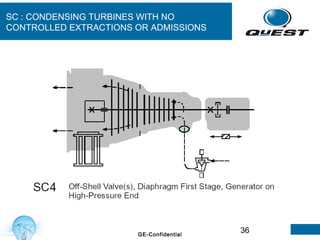

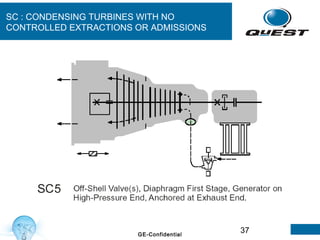

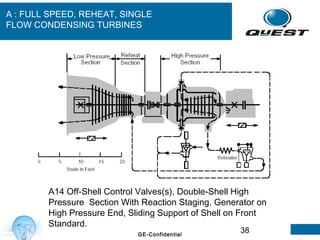

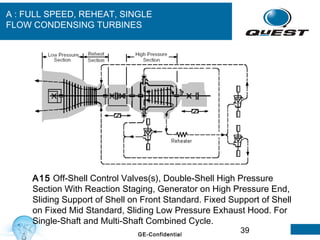

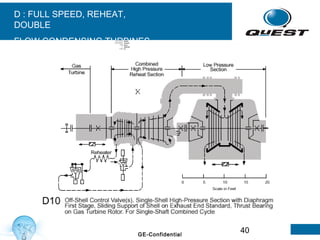

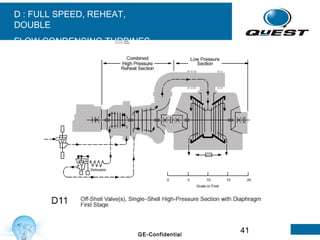

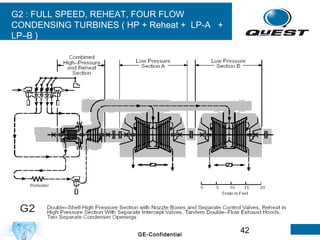

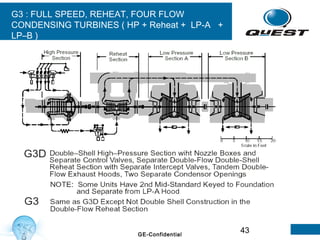

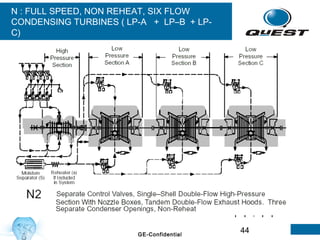

This document provides a detailed introduction to steam turbines, covering their working principles, classification, and different operating cycles. It explains the components and functioning of steam turbine systems within thermal power plants, including the concepts of multi-staging and compounding. Additionally, it outlines various types and specific designs of steam turbines used in nuclear and fossil fuel applications.