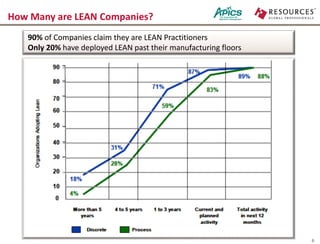

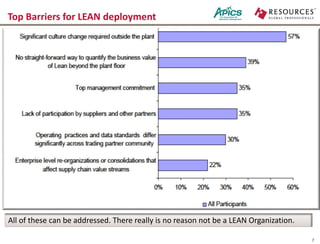

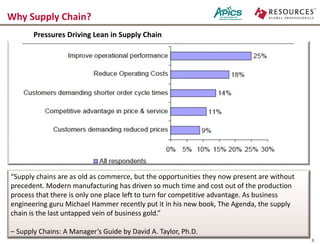

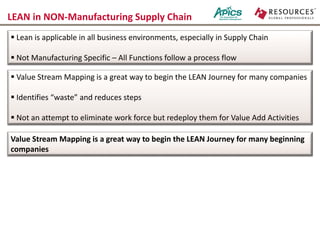

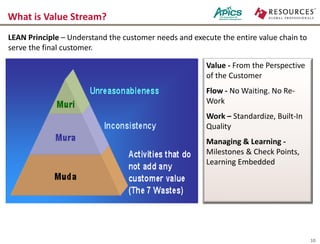

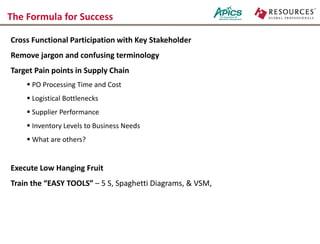

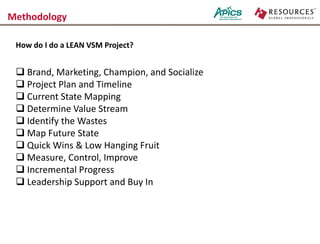

This document provides an overview of achieving lean excellence in non-manufacturing supply chains. It begins with introductions and defining the differences between Six Sigma and Lean. It then discusses industry trends showing only 20% of companies have deployed Lean beyond manufacturing. Common barriers to Lean deployment are presented. The value of applying Lean to supply chains is explained, focusing on value stream mapping to identify waste. Finally, the document outlines a Lean methodology for non-manufacturing supply chains including current and future state mapping, identifying value-added activities, and establishing metrics to ensure continuous improvement.

![4

About Myself

Elm Valle

Six years U.S. Army Officer

Experienced Consultant with Resources Global and BIG 4 FIRMS

Global Supply Chain Experience with Retail, Oil & Gas, and Chemical

MBA, Lean Six Sigma Black Belt, Project Management Certified

Membership: Lean Enterprise Institute, APICS, The Hackett Group, The Aberdeen

Group

15 Years of Operations Experience [Domestic and International]](https://image.slidesharecdn.com/02fb3ec9-a2e5-401c-997a-8d2a7d5579d3-150309143650-conversion-gate01/85/LEAN-in-a-Non-Manufacturing-Environment-4-320.jpg)

![15

Future State Mapping

Eliminate Steps & handoffs

Combine Steps

Create parallel paths

Alter sequencing

Implement Pull

Reduce / eliminate batches

Improve quality

Create organized workplace

Reduced change over

Create standard work

Eliminate unnecessary approvals

Eliminate NVA

Co-locate functions based on flow

[cross functional teams]

Improve Status

Leverage Automation](https://image.slidesharecdn.com/02fb3ec9-a2e5-401c-997a-8d2a7d5579d3-150309143650-conversion-gate01/85/LEAN-in-a-Non-Manufacturing-Environment-15-320.jpg)