1) Foundations can be either shallow or deep, with shallow foundations having a depth less than their width and deep foundations having a depth greater than 3 meters.

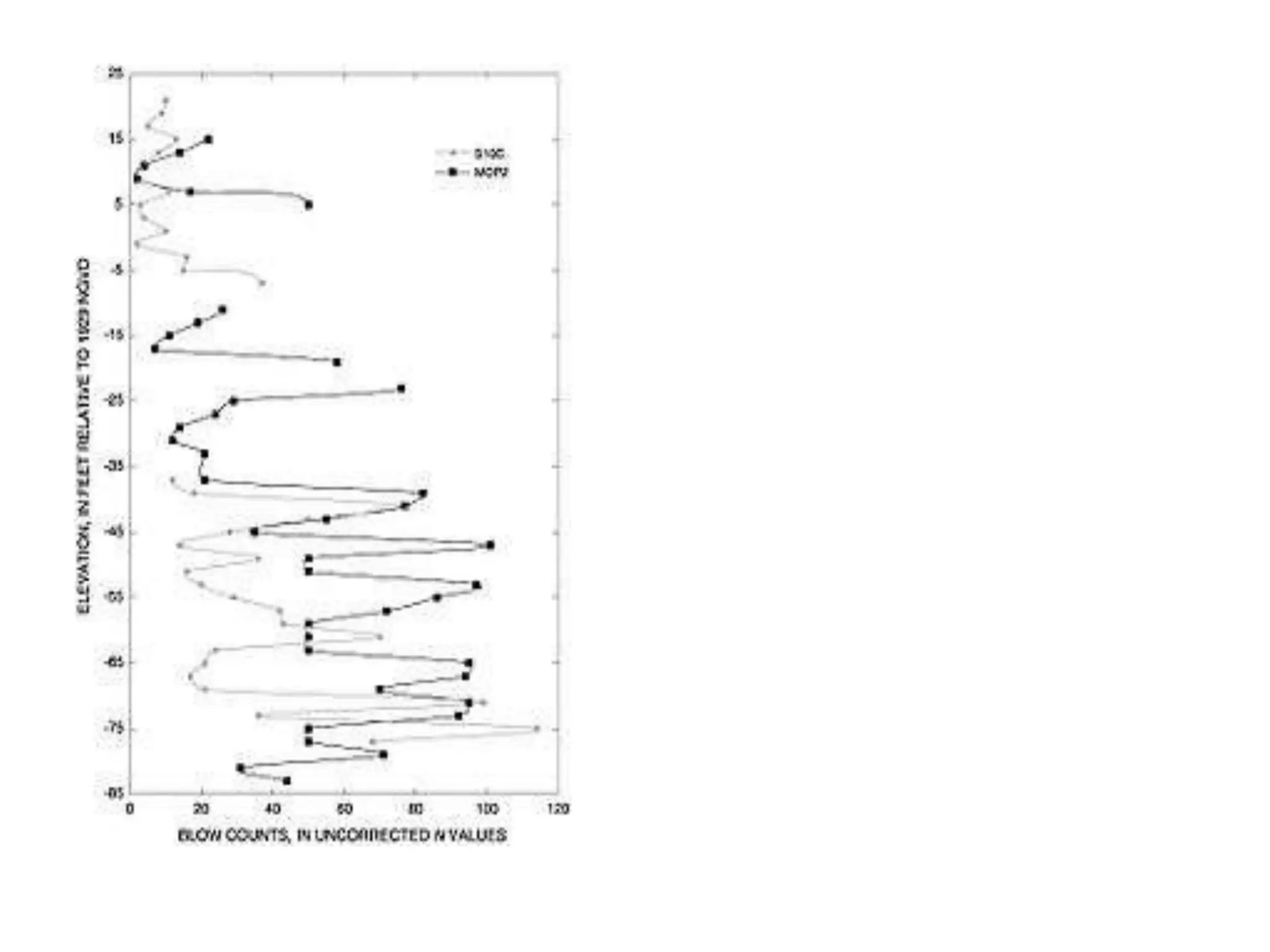

2) Before construction, soil must be tested to determine its bearing capacity and strength.

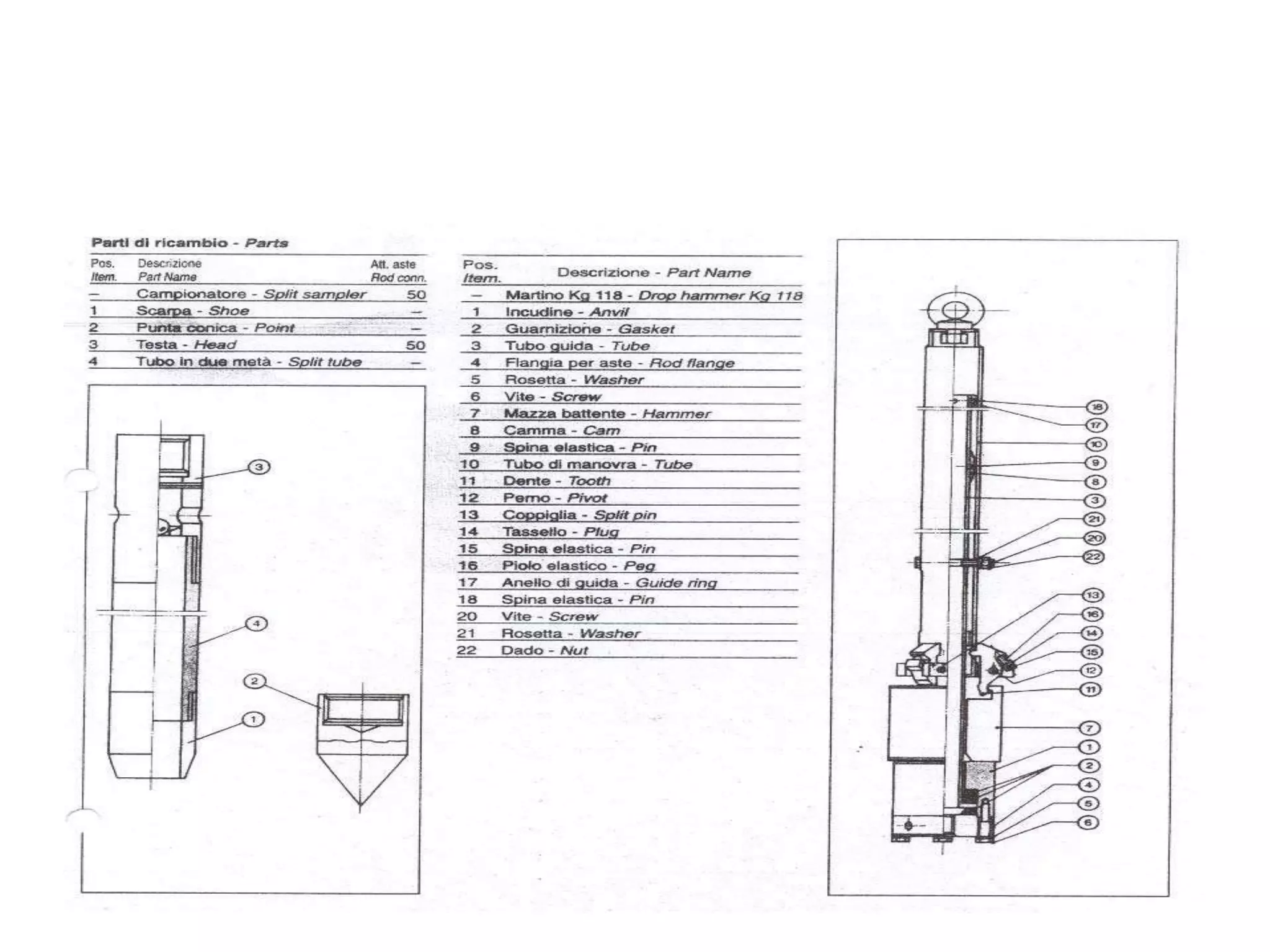

3) Standard penetration tests involve drilling a hole, lowering a split-barrel sampler attached to rods, and recording the blow count as the sampler is driven into the soil in three successive 0.15 meter increments.