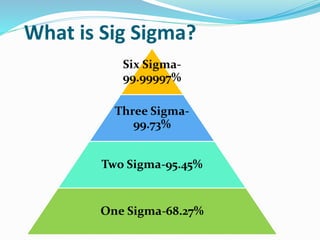

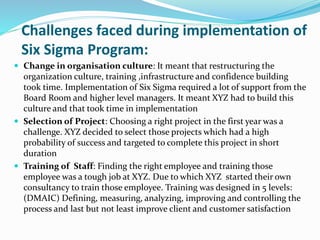

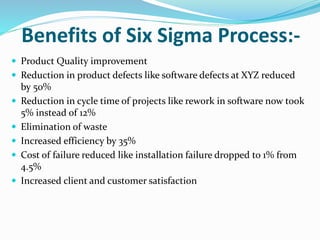

XYZ Technologies implemented a Six Sigma program to improve quality and processes. Some key benefits included a 50% reduction in software defects, cycle time reductions, and increased efficiency by 35%. However, changing the organizational culture, selecting the right initial projects, and training staff posed challenges. Six Sigma helped XYZ achieve CMM Level 5 certification and complete 91% of projects on schedule, far above industry averages. It established robust processes, quality benchmarks, and a focus on meeting client expectations to become a leading global outsourcing provider.