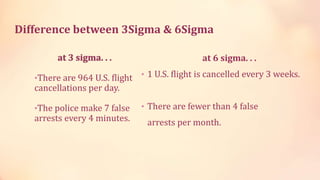

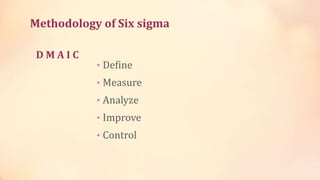

Six Sigma is a quality improvement methodology developed by Motorola, focused on eliminating defects to achieve 99.9997% defect-free processes and products. It utilizes a data-driven approach with the DMAIC framework (Define, Measure, Analyze, Improve, Control) and emphasizes continuous improvement, organizational commitment, and measuring performance to enhance business processes. While the methodology offers advantages such as increased customer satisfaction and improved profitability, challenges include a lack of interest in statistical aspects among some engineers and communication barriers between statisticians and management.