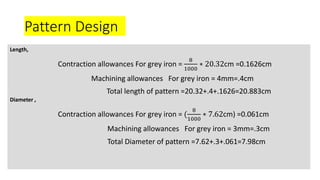

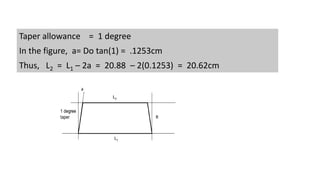

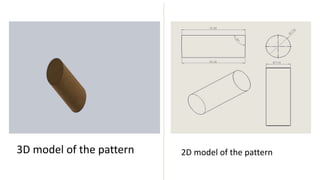

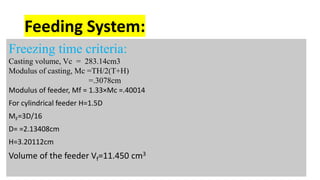

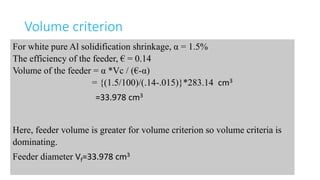

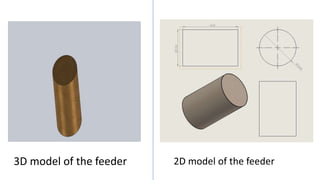

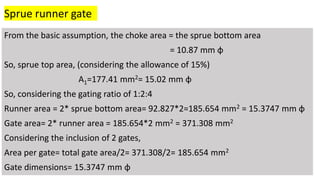

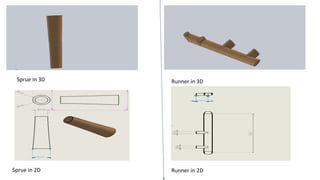

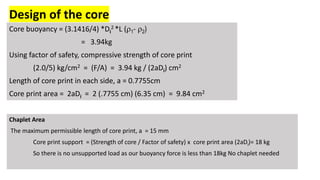

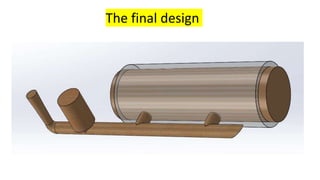

The document details the design project of a cylindrical liner focused on foundry engineering, outlining calculations for pattern dimensions, feeding systems, and gating design. Key figures include the total pattern length of 20.883 cm, feeder volume of 33.978 cm3, and a required cast mass of 3.1965 kg. Additionally, it addresses pouring time calculations, choke area specifications, and core print design, concluding with the final design considerations.