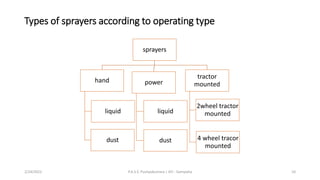

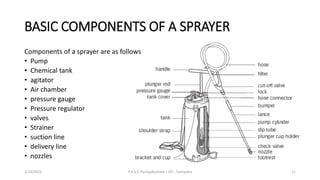

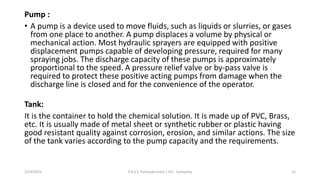

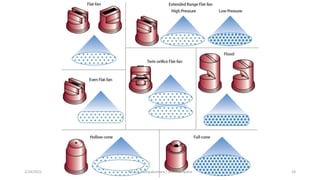

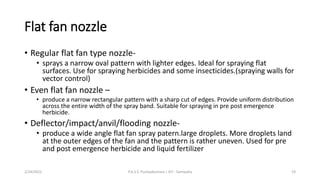

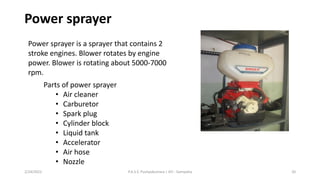

The document discusses different types of sprayers and dusters used in agriculture, including their parts, functions, calibration, operation, and maintenance. It describes common hand sprayers like hose sprayers, tank sprayers, hand-pump sprayers, and compression sprayers. Power sprayers that use small engines are also discussed. The basic components of sprayers like the pump, tank, agitator, gauges, valves and nozzles are explained. Different nozzle types for spray pattern dispersion are covered. Proper sprayer maintenance like rinsing, cleaning between chemicals, lubrication and storage are important to ensure effective application of inputs.