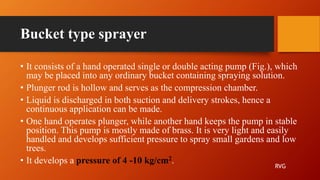

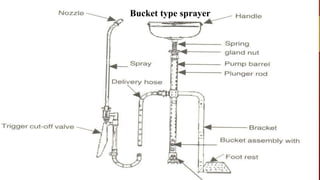

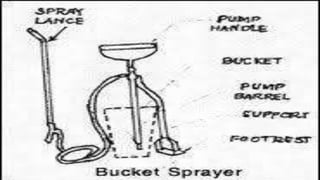

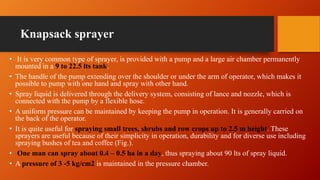

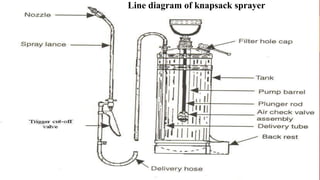

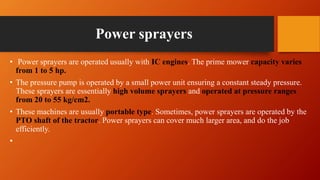

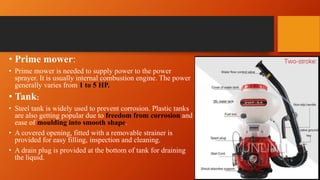

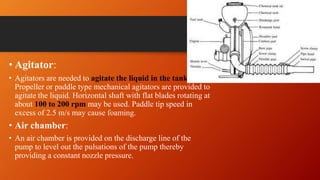

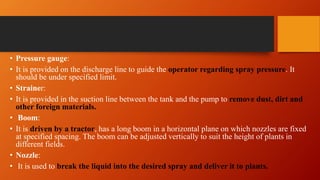

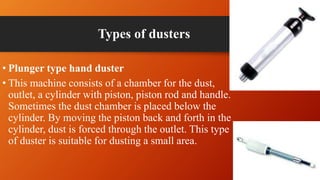

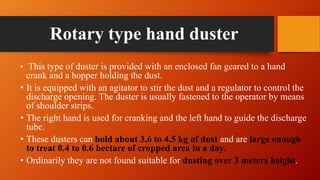

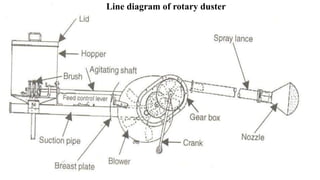

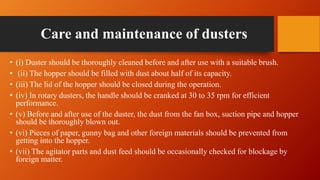

This document discusses different types of sprayers and dusters used to apply agricultural chemicals. It describes hand operated, power operated, and airplane sprayers. Key sprayer types include bucket sprayers, knapsack sprayers, and power sprayers. Power sprayers can cover large areas efficiently using a gas engine and high pressure pump. The document also outlines dusters, including plunger, rotary, and power dusters used to apply dry chemicals. It emphasizes the importance of cleaning and maintenance for sprayers and dusters.