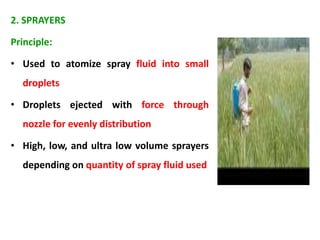

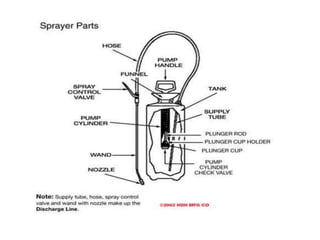

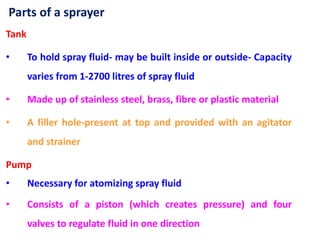

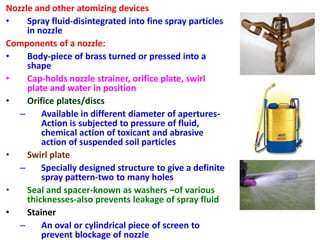

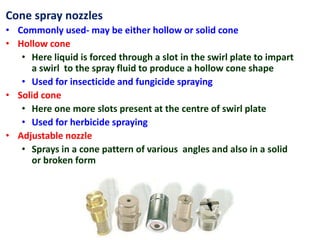

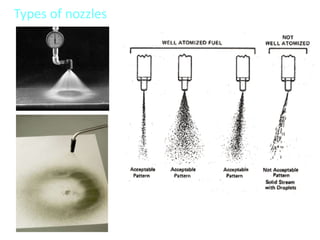

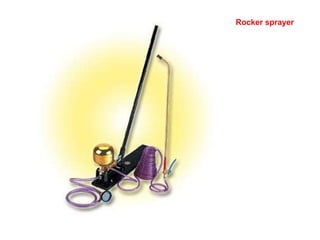

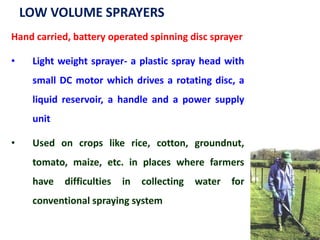

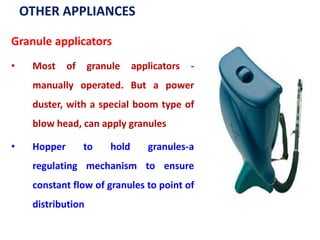

The document discusses various plant protection appliances, mainly focusing on dusters and sprayers, along with their components and functions. It details types of dusters such as rotary, knapsack, and power-operated, as well as different types of sprayers including manually operated and power sprayers, highlighting their uses and mechanisms. Additionally, other appliances like flame throwers and granule applicators for pest control are mentioned.