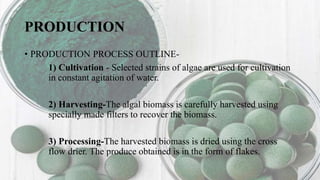

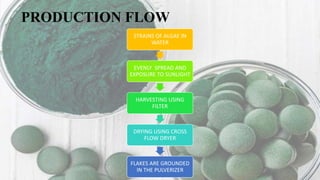

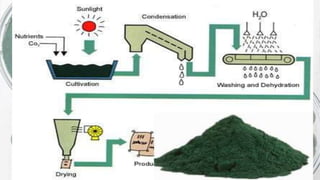

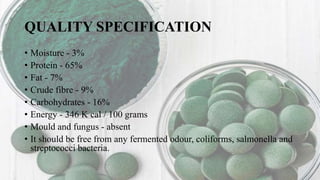

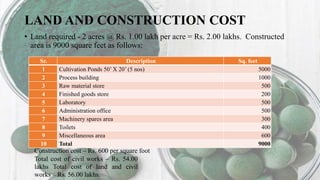

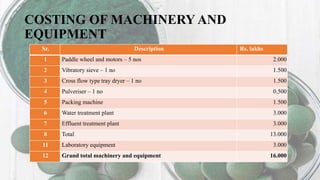

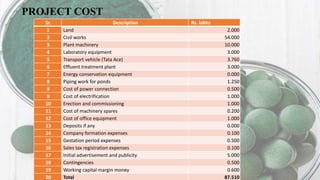

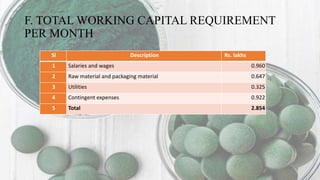

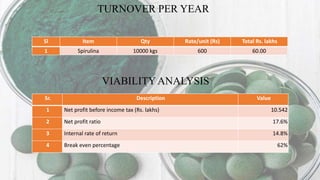

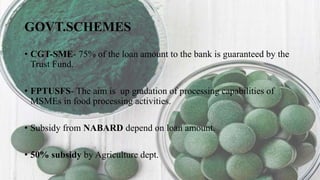

This document provides information about spirulina production including its cultivation process, quality specifications, cost estimation, financial analysis, health benefits, target market, government schemes, and success stories. Spirulina is a blue-green algae grown through cultivation in warm alkaline water, harvesting using filters, and drying. It is a superfood known for its high protein, nutrient, and antioxidant content. Production costs, monthly expenses, and projected profits are estimated to determine viability.