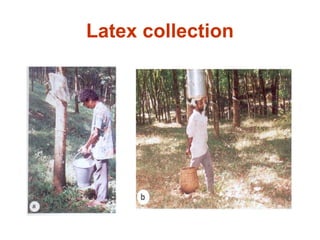

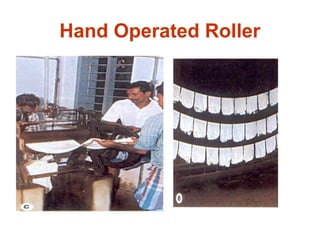

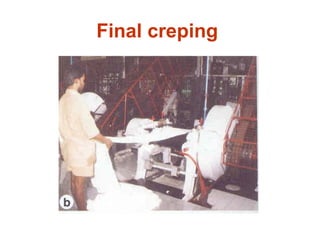

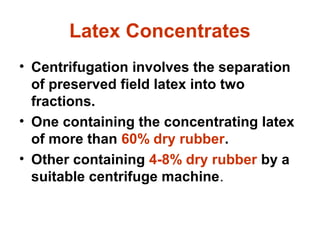

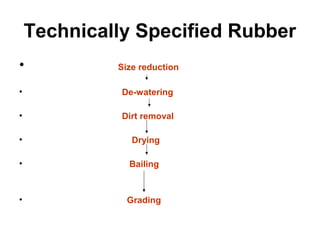

India is the third largest producer and fourth largest consumer of natural rubber in the world. The automotive tire sector accounts for 50% of India's rubber consumption. The document discusses the various stages of rubber production including latex collection, processing, and different marketable forms. The key types discussed are sheet rubber, crepe rubber, block rubber, and technically specified rubber which are used in various industries like tires, footwear, and medical products.