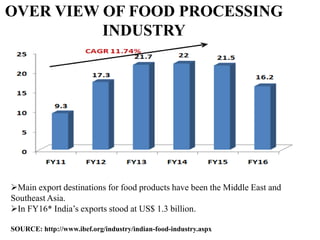

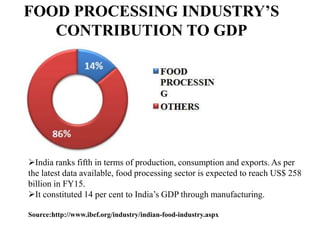

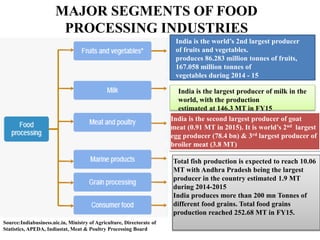

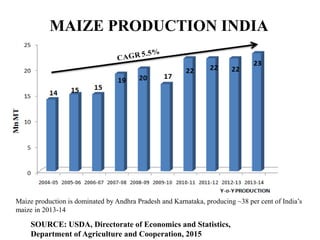

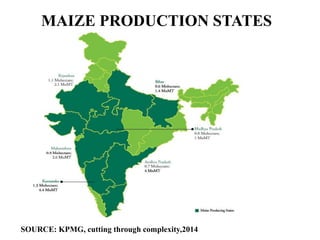

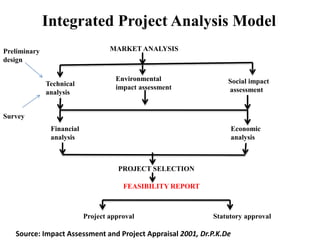

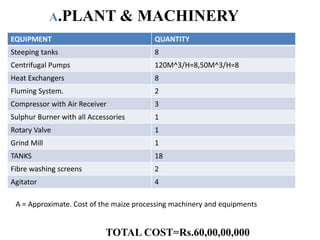

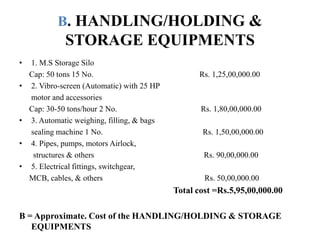

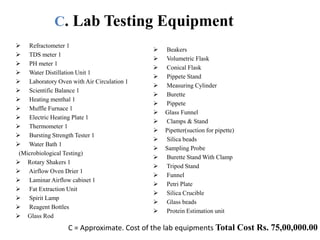

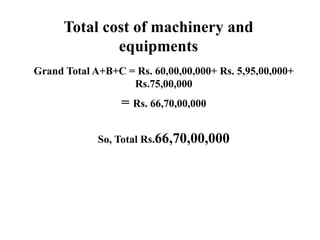

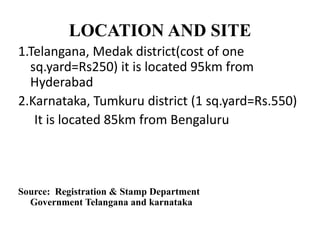

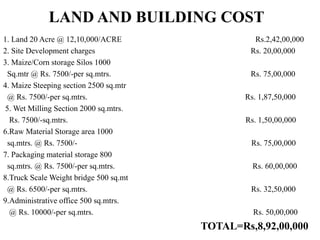

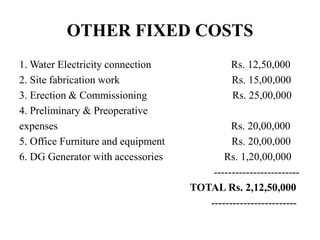

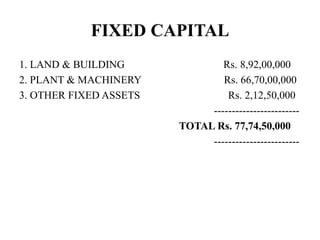

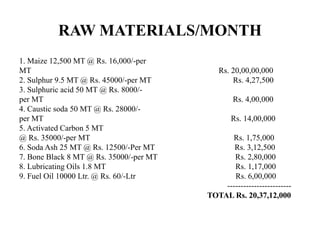

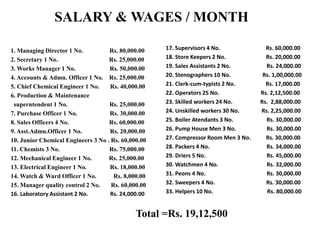

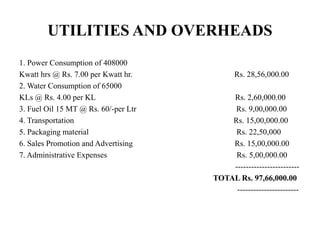

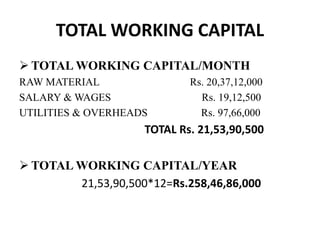

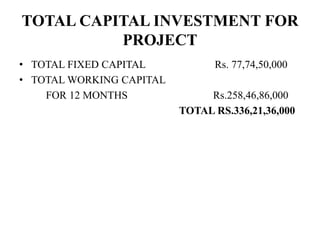

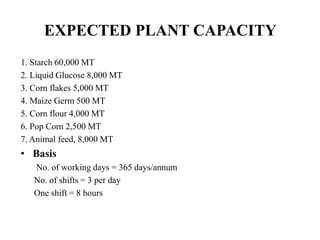

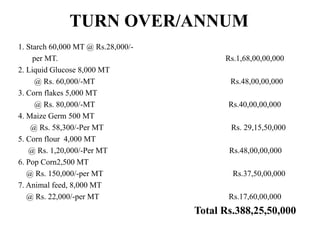

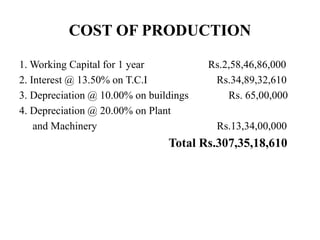

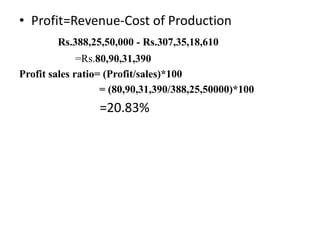

The document is a project feasibility report for a food processing company focusing on maize processing in India. It outlines the current status of the food processing industry, including major production sectors, machinery and equipment costs, financial analyses, and expected plant capacity. The total capital investment required for the project amounts to approximately Rs. 336.21 crores, with anticipated revenues of Rs. 388.25 crores and a profit of Rs. 80.90 crores.