The document summarizes an experiment that investigated the effect of ytterbium doping on the grain growth of magnesium aluminate spinel. It was found that doping with 500 ppm of ytterbium caused an increase in grain growth and a decrease in abnormal grain growth compared to undoped samples. Electron backscatter diffraction and microscopy were used to analyze the grain size distributions of doped and undoped samples sintered for 1, 2, and 4 hours. Probability analysis showed that the grain size data fit a gamma distribution better than a log-normal distribution. Ytterbium doping resulted in consistently larger grain sizes compared to undoped samples.

![George J Ferko V 1

The Effect of Ytterbium on the Grain Growth of Magnesium Aluminate Spinel

George J. Ferko V 1

12/10/2011

Abstract

Pressureless sintering of undoped magnesium aluminate spinel and spinel doped with 500

ppm of ytterbium has been investigated. It has been found that the addition of ytterbium at this

level causes an increase in grain growth and a decrease in abnormal grain growth. The

cumulative distribution functions of the grain size data have been evaluated using probability

plots and it has been found that the data fits a gamma distribution function much better than a

log- normal distribution function. This probability analysis allows for the grain size data to be

observed in a much more meaningful way then has been previously reported for this system. It

has also been found that the bi-modal, or duplex microstructure, often observed in spinel occurs

in undoped samples, thus it cannot be attributed to the presence of a specific dopant at this time.

Introduction

Polycrystalline magnesium aluminate spinel (spinel) has been found to have attractive

properties for the production of transparent armor and radar and detector domes and windows.

The recent availability of high purity spinel powders has brought spinel to the forefront of

transparent armor, window, and dome design by allowing for spinel to be manufactured with

high transparency in the midwave infrared (MWIR) range and the ultraviolet-visible (UV-VIS)

range[1-8]. Spinel has consistently exhibited high fracture toughness and hardness as well [9-

17]. When we combine these properties with the relatively low density of spinel compared to

other popular transparent armor materials such as AlON or sapphire the study of spinel becomes

an even more attractive venture [18].

Research on the spinel system over the last 50 years has focused on the study of sintering

additives, or dopants, and their ability to produce economical and consistent commercial spinel

[8]. Despite a large body of work precise control over the microstructure of spinel has yet to be

realized. Spinel continues to exhibit a common duplex microstructure where large grains seem

to be imbedded in a matrix of much smaller grains, a feature that has been attributed to the use of

LiF as a sintering additive [19]. This is particularly troubling in the spinel system as its

transparency depends on the porosity of the final product and the mechanical properties of spinel

are highly dependent on average grain size and grain size distribution. In order to improve spinel

so that it may reach its full potential it is necessary to analyze the sintering kinetics of spinel in

relation to certain model additives or dopants. The analysis of the sintering kinetics of doped

spinel should be done in conjunction with observation of the grain boundaries using high-angle

annular dark field scanning transmission electron microscopy (HAADF STEM) and high-

resolution STEM so that the structure at the grain boundary, or the grain boundary complexion,

can be related to the sintering kinetics. Rare earth dopants such as La, Dy, Eu, and Yb have

recently been found to be easily observable at the grain boundaries of spinel using HAADF

STEM by Perkins, et al. [20-22]. The drastically different atomic number of these dopants from

the molecular constituents of spinel makes the z-contrast produced by HAADF STEM

exceptional.

1

Graduate Student – Lehigh University

Email: george.ferko.v@gmail.com

Phone: 610.597.8007](https://image.slidesharecdn.com/0a2316cd-e704-4de0-9f5d-a5a44bf5f694-161002072737/75/Spinel-Yb-grain-growth-and-prob-analysis-1-2048.jpg)

![George J Ferko V 2

Recently published data by Benamuer, et al. has shown a systematic evaluation of the

sintering kinetics of spinel using pressureless sintering and a commercially available high purity

spinel powder [23]. The experiment described in this report will, in many ways, be modeled

after the work done by Benamuer except a Yb dopant will also be used so that the grain

boundary structure can be observed at a later point. The goal of this experiment is to establish

the effect that Yb doping has on the grain growth and the grain size distribution of spinel as an

initial step to further understanding the microstructural development of spinel.

Experimental Methods

A commercially available high purity spinel powder (S30CR, Baikowski, Annecy,

France) was used as the starting powder. The impurity data for this powder, seen in table 1, is

available from the supplier and agrees well with the inductively coupled plasma spectroscopy

performed by Benamuer [23]. A Yb dopant

precursor in the form of high purity ytterbium

nitrate hydrate was obtained from (Alfa Aesar,

Ward Hill, MA). Ytterbium nitrate hydrate readily

dissolves in most solvents making it easier to

homogeneously distribute the dopant in the powder.

The dopant precursor is dissolved in 200 proof

ethanol and the powder is combined with the dopant

in ethanol to produce a doping level of 500ppm Yb.

The powder and dopant are mixed in a PFA jar

using a magnetic stirring rod under vacuum at a

temperature of 80o

C to facilitate the evaporation of the ethanol. This mixing method was used to

preserve the stoichiometry and purity of the powder. All of the labware used is cleaned using

aqua regia and hydrogen peroxide to remove any potential contaminants.

Both the doped and undoped powders are formed into pellets by uniaxially pressing the

powders in a high density polyethylene die and punch arrangement at 35 MPa. A large sample

size is chosen, 1” diameter by ¾” height, because Mg evaporation has been observed at the

surfaces of spinel samples when they are sintered in a reducing atmosphere [19]. The density of

the green pellets at this stage was not measured to prevent contamination and because the pellets

are very fragile at this stage. The pellets are cold isostatically pressed at 275 MPa for 2 minutes

giving them a green density of about 45%. The pellets are then packed in powder of the same

composition inside high purity alumina crucibles in a double crucible arrangement in preparation

for sintering. The sintering is performed in a high temperature graphite furnace (Thermal

Technologies, Santa Rosa, CA) in a 5% hydrogen 95% nitrogen reducing atmosphere. The

samples are first raised to 800o

C for 1 hour in a calcining step to remove the nitrates, water, and

hydrocarbons from the samples. The Yb precursor has been found to convert entirely into Yb2O3

at 550o

C so the calcining temperature and time should successfully remove the impurities from

the sample [24]. The furnace temperature is then raised to 1800o

C and held for dwell times of 1,

2, and 4 hours.

The large pellets were sectioned so that a 5mm by 5mm by 5mm square was removed

from the center of the pellet. The sample was then ground and polished in preparation for

EBSD. In order to ensure that there was little surface damage from the grinding a minimal force

of 4 MPa was used for all grinding and polishing steps and after each step the sample heights

Table 1: Impurity data for the S30CR

powder from Baikowski [23].

Baikowski S30CR Powder Purity

S (ppm) 800-900

K(ppm) 40

Na(ppm) 11

Fe(ppm) <10

Ca(ppm) <10

Si(ppm) <10](https://image.slidesharecdn.com/0a2316cd-e704-4de0-9f5d-a5a44bf5f694-161002072737/85/Spinel-Yb-grain-growth-and-prob-analysis-2-320.jpg)

![George J Ferko V 3

were measured to ensure that four times the particle size of the previous grinding medium had

been removed to minimize the surface damage in the sample.

In preparation for EBSD the samples were given a 4nm coating of Ir to prevent charging

effects. EBSD patterns were obtained in a Hitachi 4300 Cold Field Emission High Resolution

Scanning Electron Microscope equipped with an EBSD detector using the EDAX TSL/OIM data

collection and analysis software. Each sample was scanned 10 to 15 times in order to obtain at

least 1000 grains per sample. Scans were done at varying magnifications and step sizes to ensure

that very small grains or very large grains were not absent in the scans of each sample. The

EBSD data for this experiment is meant to be used to automatically determine the grain size

distribution. The grain size distribution provides us with a lot more information than just the

average grain size and can be helpful in evaluating the abnormal grain growth in our samples.

The raw data cannot simply be measured for grain size, it must first be cleaned using

grain dilation and partitioned to eliminate grains that are only made up of a few pixels and are

either false readings from pores or are grains that are too small to be mapped with the EBSD step

sizes used. Then the data is overlaid onto the SEM signal to make sure the microstructure

produced is representative of what is actually there. Next the edge grains are subtracted out and

this data is used to form the grain size distributions. A schematic of the data processing is shown

in figure 1. By varying the step size and magnification any large grains excluded because they

were on the edge of the frame should be accounted for by other scans.

Figure 1: Schematic of the data processing used to go from the raw EBSD data to the data used

for the analysis of the grain size distribution.

The grain size data is binned to produce histograms of the grain size distributions;

however, in order to properly analyze the data it must be evaluated as a cumulative distribution

function and then plotted on a probability plot to see how well the data fits a distribution

function. The most common distribution function used is the log-normal distribution function

[25-27]; however, it has been found that some data fits the gamma distribution much better [28]

so both distributions are used in the statistical analysis. The distributions are used because they

are multiplicative like grain growth and the two distributions are actually quite similar. The](https://image.slidesharecdn.com/0a2316cd-e704-4de0-9f5d-a5a44bf5f694-161002072737/85/Spinel-Yb-grain-growth-and-prob-analysis-3-320.jpg)

![George J Ferko V 5

The scale of the micrographs is not the same between different sintering times; however, the

scale is the same between the doped and undoped samples for each time. In figure 2a there are at

least two different kinds of grains present in what could be called a duplex microstructure. It

should be noted that these sorts of grain size distributions in spinel are often attributed to Li and

F ions, due to the common use of LiF as a dopant in spinel, causing an inhomogeneous

coarsening effect [19]; however, no LiF is present in this sample which makes this result

somewhat significant and might mean that the inhomogeneous coarsening or abnormal grains are

due to the other impurities found in the starting powders. Throughout the undoped sample very

large grains from 20 to 70um in diameter are observed as well as grains that range from 1 to 5

um in diameter. These large grains might be considered abnormal grains and the analysis of the

grain size distributions, to be discussed later, will help to identify whether or not the grains are

growing abnormally. There is a clear difference in grain size between the doped and undoped

samples even at 1 hour of annealing time. The micrographs in figure 2a and 2b show clearly that

even at a one hour dwell time the Yb-doped grains have grown to be much larger than those of

the undoped grains. The histograms of the grain size distributions for all of the samples are

shown in figure 3.

(a) (b)

(c) (d)

(e) (f)

Grain Size (µm) →

Figure 3: Plots of the grain size histograms for the (a) undoped 1 hour and (b) Yb doped

samples, the (c) 2 hour undoped and (d) Yb doped samples, and the (e) 4 hour undoped and (f)

Yb doped samples.

In figure 3b and 3a it can be seen that the grain size distribution for the doped grains in the 1

hour sample is much broader than that of the undoped grains. In the doped one hour sample we

have a range of grain sizes from 5-60um where it is not clear if any of the grains are growing

abnormally. This is in contrast with the undoped one hour sample where the distribution is very

sharp so that any grains outside of the distribution are easy to spot.

Frequency→](https://image.slidesharecdn.com/0a2316cd-e704-4de0-9f5d-a5a44bf5f694-161002072737/85/Spinel-Yb-grain-growth-and-prob-analysis-5-320.jpg)

![George J Ferko V 6

In the two hour samples in figure 2c and d and figure 3c and d the grain size distributions

have broadened significantly as well as having increased in grain size. The broadening of the

undoped sample grain size distribution may be occurring because the abnormal grains are

becoming impinged and beginning to slow down while the normal grains continue to coarsen.

The 4 hour samples in figure 2e and f and figure 3e and f exhibit grain size distributions very

similar to those of the 2 hour samples. Significant broadening of the grain size distrtributions is

not discernable, however, as would be expected the grains have continued to grow in what

appears to be pure coarsening.

An attempt was made to quantify the pore size distribution by binarizing the SEM signal

from the EBSD scans, however, because the magnifications used were meant to capture the

range of grain sizes and not that of the pore sizes the data comes out nonsensical so the pore size

data that was obtained will not be included in this report as it cannot be quantified properly. This

also makes it impossible to fit any sort of microstructural development models for porous

compacts to the grain growth and densification data. It should be noted, however, that using

similar methods Benamuer, et al., were able to produce nearly fully dense samples in the range

of sintering times used here [23]. This difference may be due to the large sample size used here.

In figure 4 we see a plot of the log average grain size versus log time which shows that

the grain size of the Yb-doped grains is consistently higher than that of the undoped grains. This

shows that the Yb dopant is producing an increase in mobility that allows the spinel grains to

grow at a faster rate.

Figure 4: Plot of the log average grain size versus the log time for all of the samples produced.

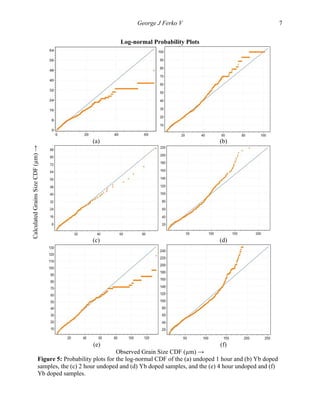

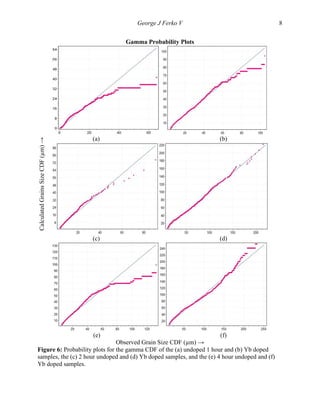

As stated earlier the average grain size and the histograms do not show enough

information to convincingly say whether or not grains are growing abnormally so cumulative

distribution functions were applied to the grain size data and probability plots were produced to

determine which CDF the grain size data fits best and which grains deviate significantly from

that distribution function. The plots of the CDFs, i.e. cumulative percent versus CDF, are not

included here to save space. In figure 5 the probability plots for the log-normal distributions for

all of the samples are shown. The plot for each sample is shown individually because the large

number of data points from each sample becomes very confusing on a consolidated plot. Also,

500 ppm Yb-

doped

Undoped

0

0.2

0.4

0.6

0.8

1

1.2

1.4

1.6

1.8

2

3.5 3.6 3.7 3.8 3.9 4 4.1 4.2

log(Ḡ)(µm)

log(t) (s)](https://image.slidesharecdn.com/0a2316cd-e704-4de0-9f5d-a5a44bf5f694-161002072737/85/Spinel-Yb-grain-growth-and-prob-analysis-6-320.jpg)