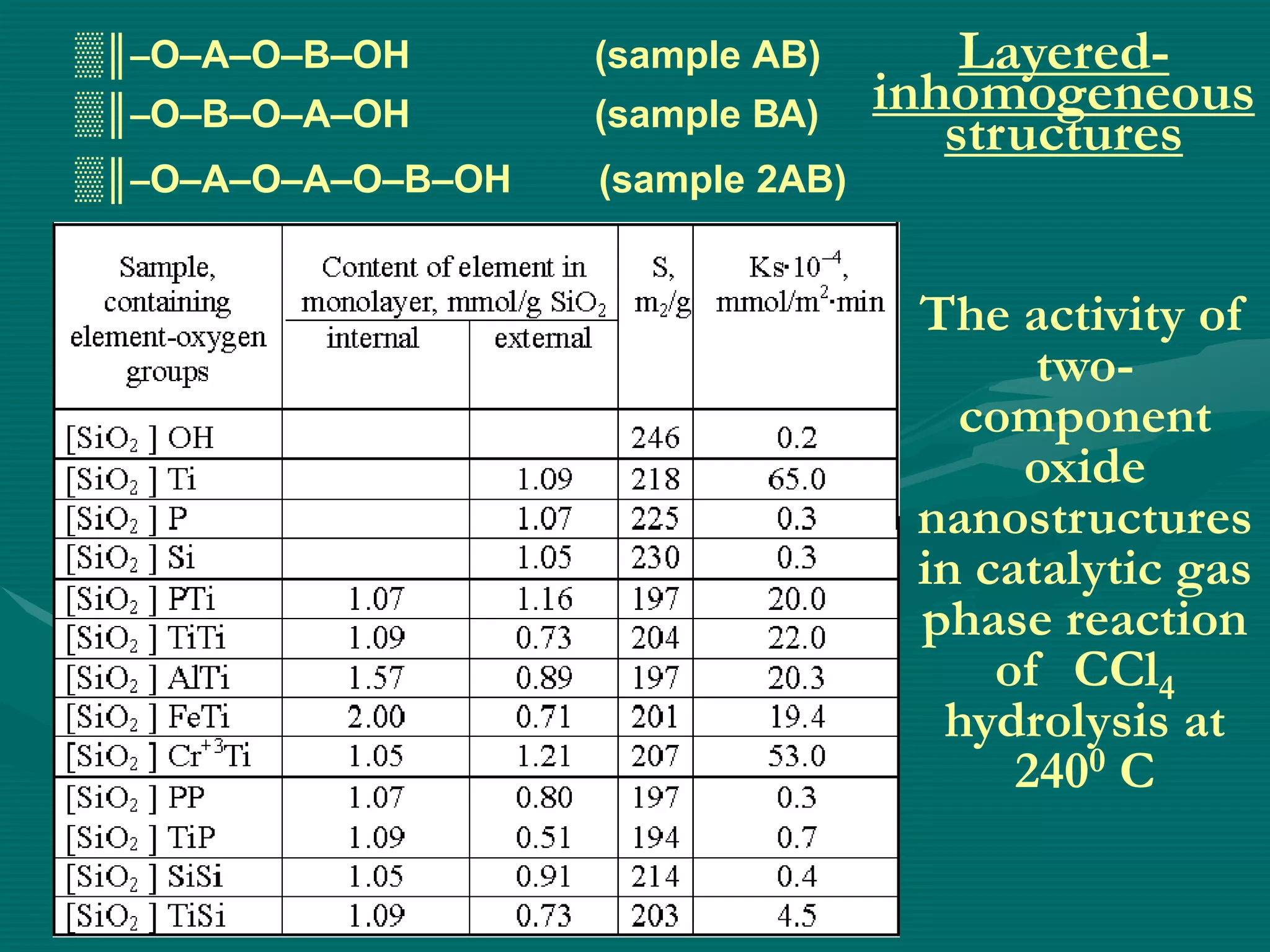

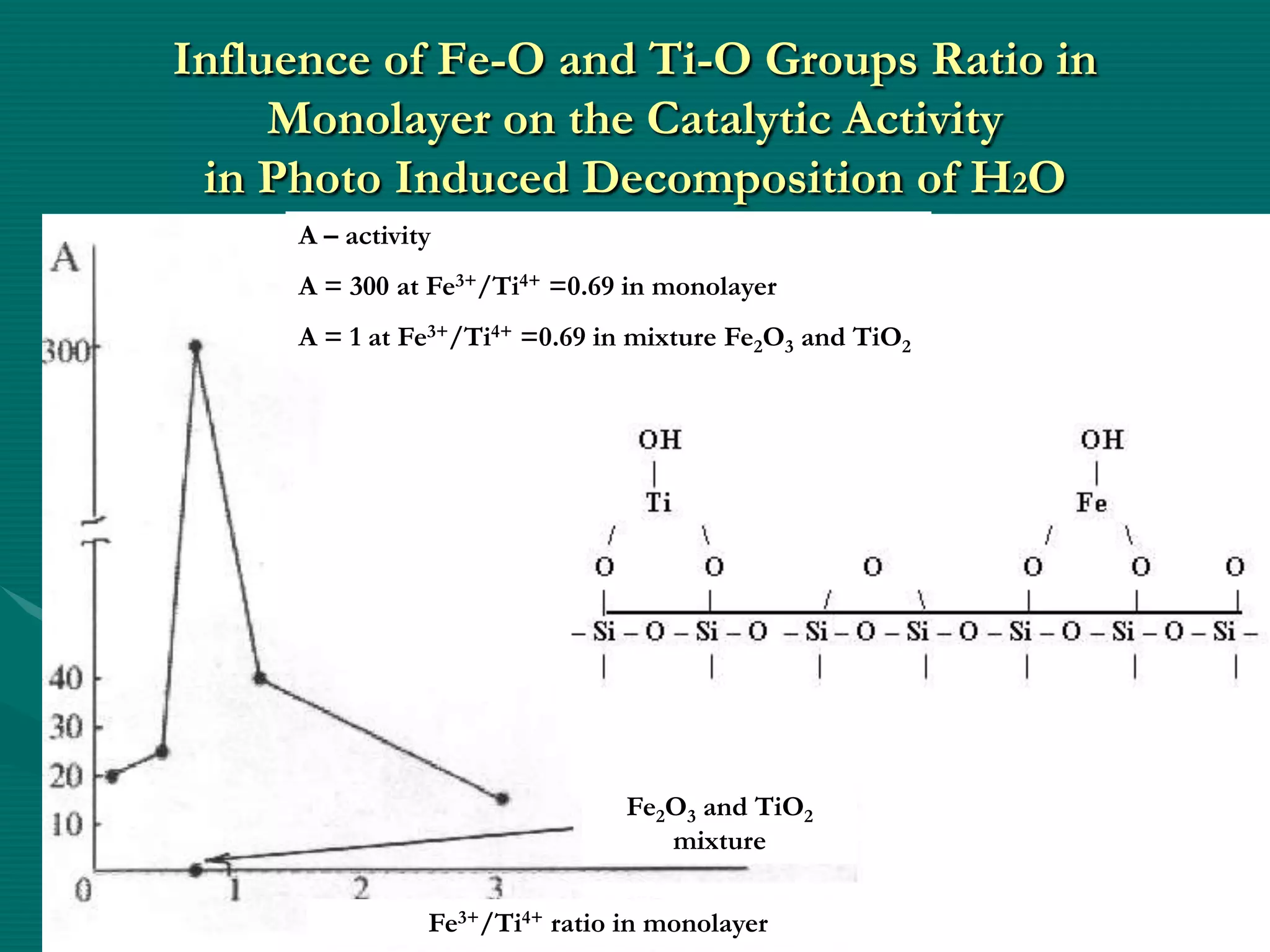

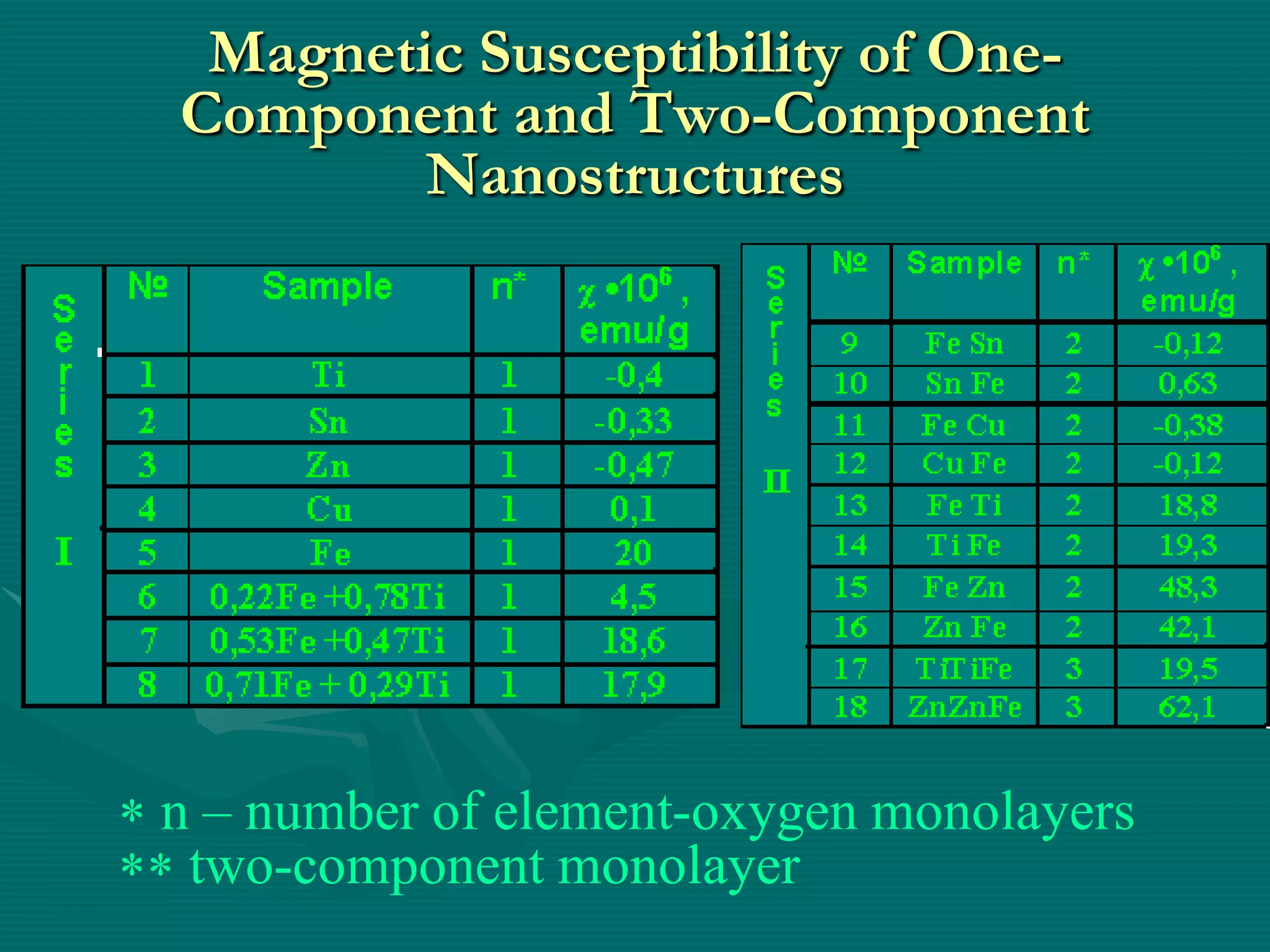

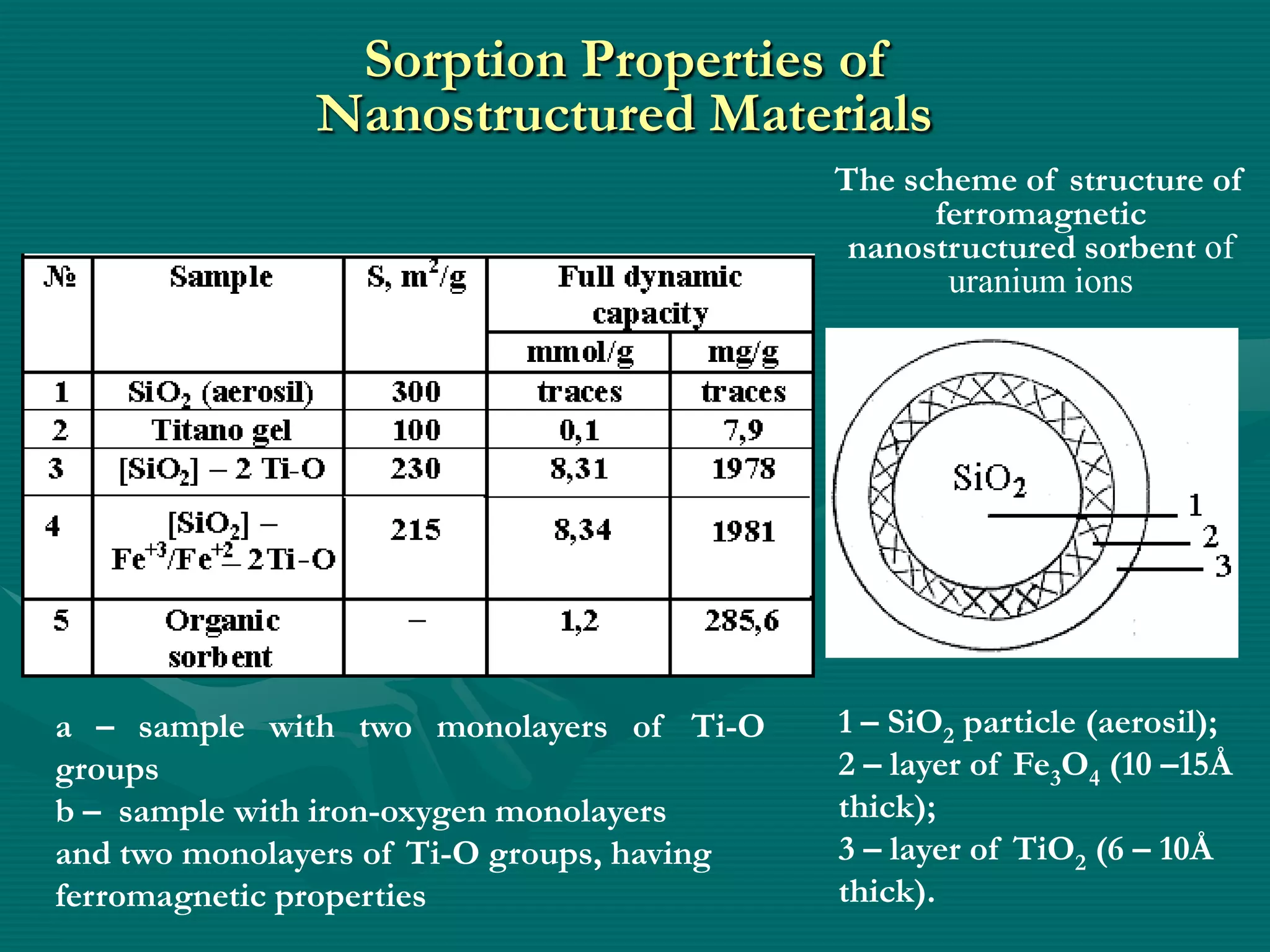

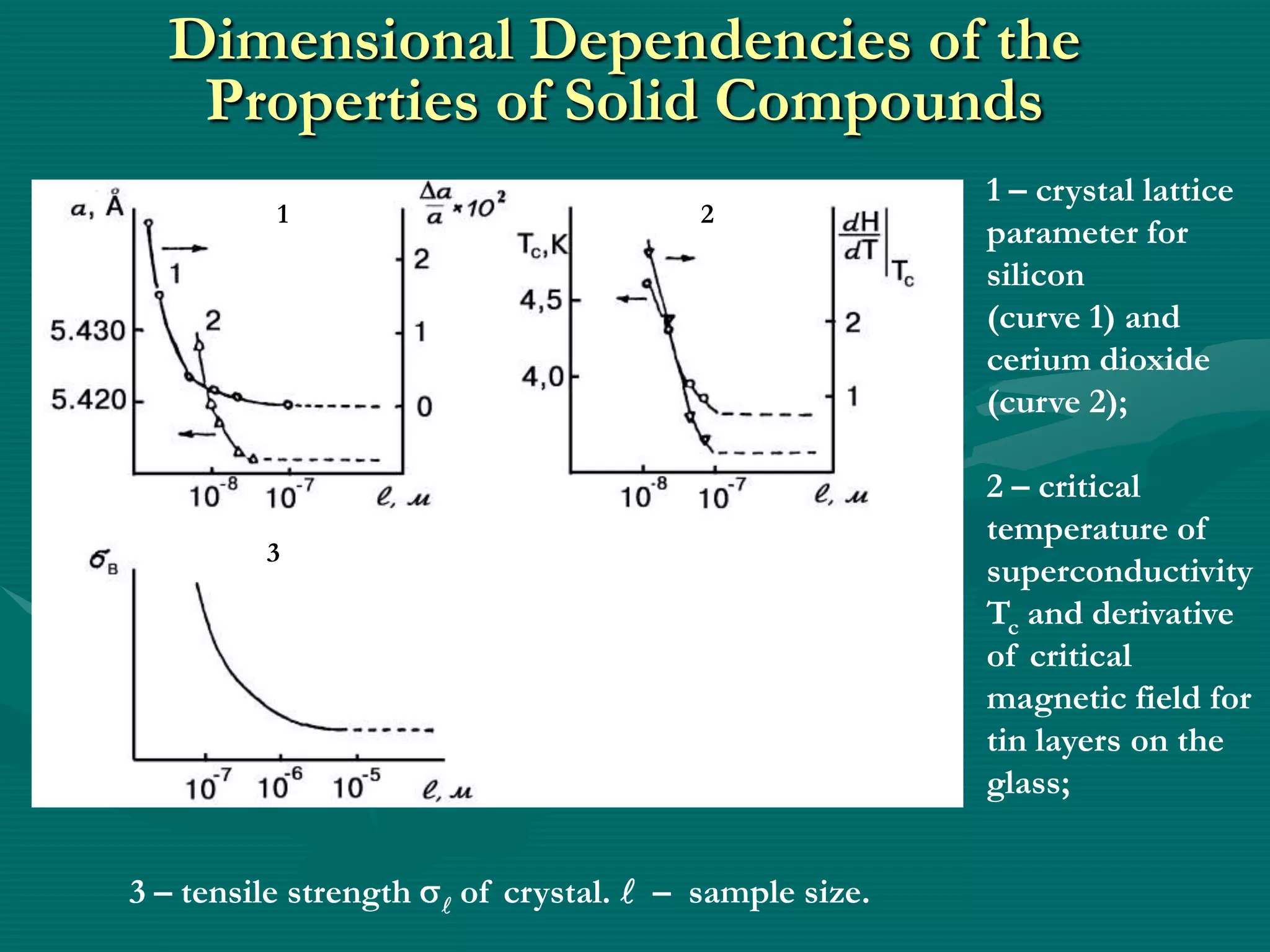

The document discusses nanostructured materials and their properties. It presents several schemes describing different types of two-dimensional nanostructures on silica surfaces based on homogeneous or periodic distribution of element-oxygen layers. It also examines the dimensional dependence of material properties on size, and how the ratio of chemical components in multi-layer nanostructures can influence properties like catalytic activity and magnetic susceptibility. Finally, it concludes that a scientific foundation now exists for designing highly organized nanostructured solids and materials by controlling composition and structure at the nanoscale.

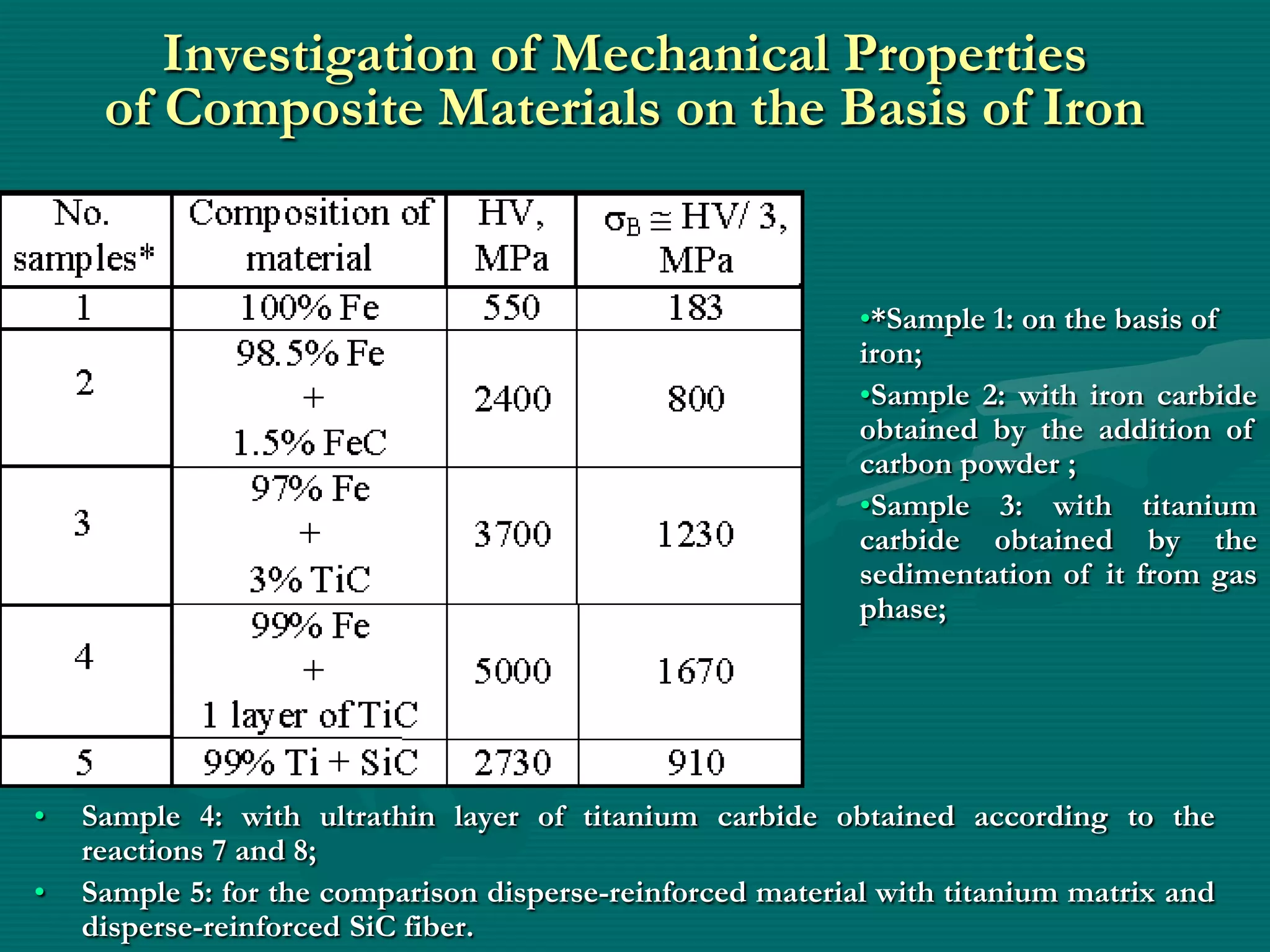

![The State of Two-Dimensional

Nanostructures on the Silica Surface

• А – with homogeneous character of distribution of

chemical composition and state, for example, monolayers

of element-oxygen groups of the same chemical

composition, l – monolayer thickness, L – layer thickness,

l1 = l2 = l3 = l4; 1– for example, Ti–O monolayers.

• B – periodic distribution of element-oxygen layers

along z axis, (L – layer thickness) consisting of the certain

quantity of monolayers, for example, according to the

scheme: 1 –Fe-O groups, 2 –Ti-O groups (a – two-layer

group, l1 = l2 , б, в – four-layer group l1 = l3 и l2 = l4 ).

• C – aperiodic distribution of element-oxygen layers

along z axis, four-layer structure l1 l2 l3 l4

• D – aperiodic distribution of atoms on the plane of

surface monolayer, top view: х –Fe-O groups, о –Ti-O

groups; а, б – different ratios of groups Fe-O and Ti-O.

• E - aperiodic distribution of “zero-dimensional"

structures on the plane of support: 1 –Si , 2 – [ Fe]](https://image.slidesharecdn.com/prezenteng-120831060857-phpapp02/75/Prezent-eng-2-2048.jpg)

![Energetic Diagram of Reaction with Kinetic and

Thermodynamic Control

[SiO2]m-1O1,5SiOH + Cl2 [SiO2]m-1O1,5SiCl SiCl4

A B C

1 – reaction A → B

dominates, product

B is kinetically stable;

Free Energy

2 – side reaction A → C

dominates;

3 – reaction A → B

dominates, but the

product B is kinetically

unstable and converts

rapidly into C.

Reaction coordinate](https://image.slidesharecdn.com/prezenteng-120831060857-phpapp02/75/Prezent-eng-3-2048.jpg)

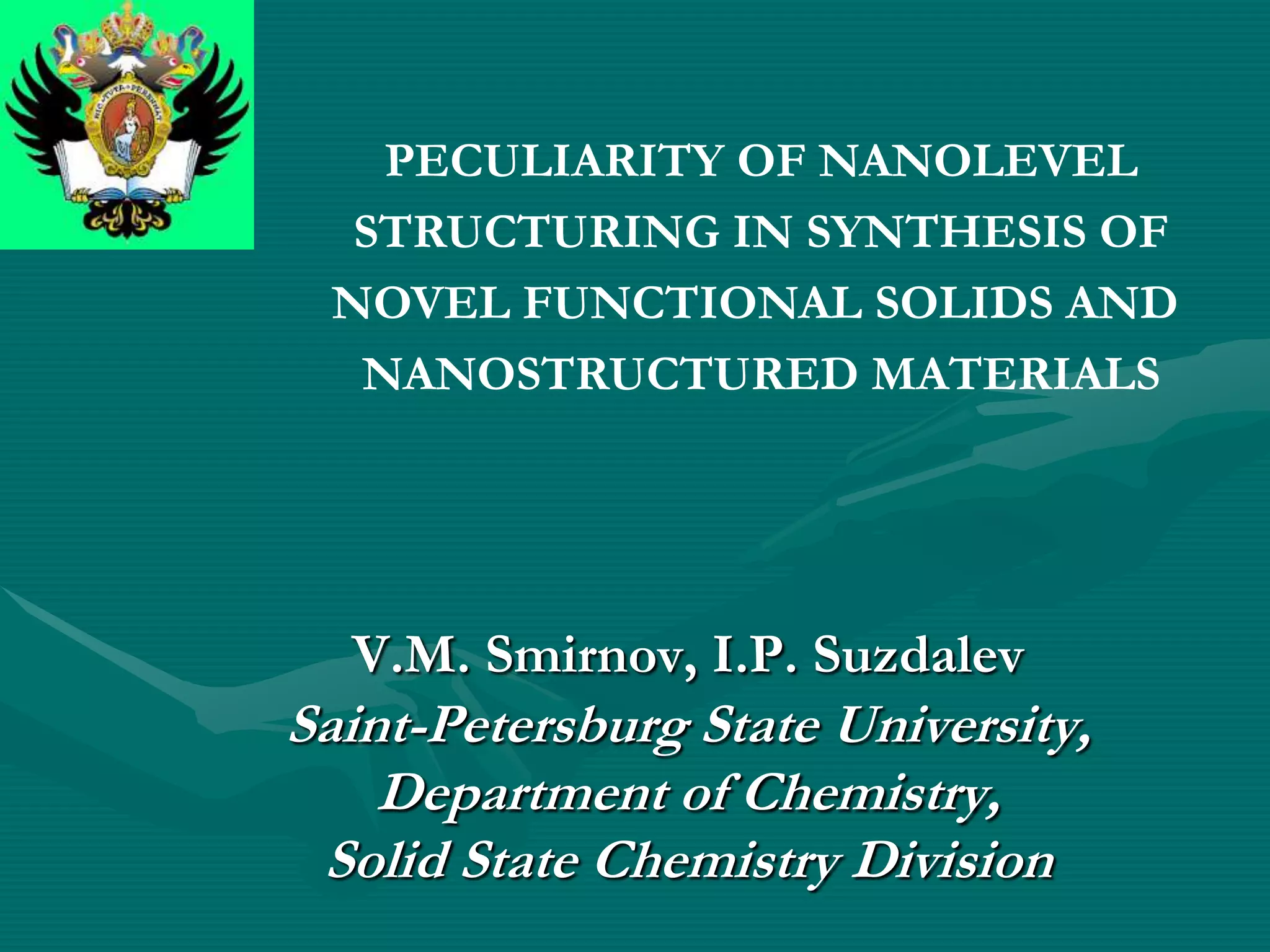

![The Scheme of State of

Solid Chemical Compounds

3

1 – initial metal

oxide (MOn);

2

2–surface chemical

compound [MO]n-1

1

(M– O)2 Si(OH)2 ;

3–spatially divided

compound [MOn]–

[SiO2];

1 – conditional

(internal) border of

division](https://image.slidesharecdn.com/prezenteng-120831060857-phpapp02/75/Prezent-eng-7-2048.jpg)

![Generalized View of Dependence of Properties

on Size of Chemical Matter

Subcrystal

Property

Massive

crystal a – for the solid matter;

b – change of the value of

specific Surface S depending on

Size of Solid Matter ()

b [according to V.B. Aleskovskii].

1 – size of minimal solid matter

(nanoobject);

2 – size of dispersed solid state

(micro object);

3 – massive (macroscopic) solid.](https://image.slidesharecdn.com/prezenteng-120831060857-phpapp02/75/Prezent-eng-10-2048.jpg)

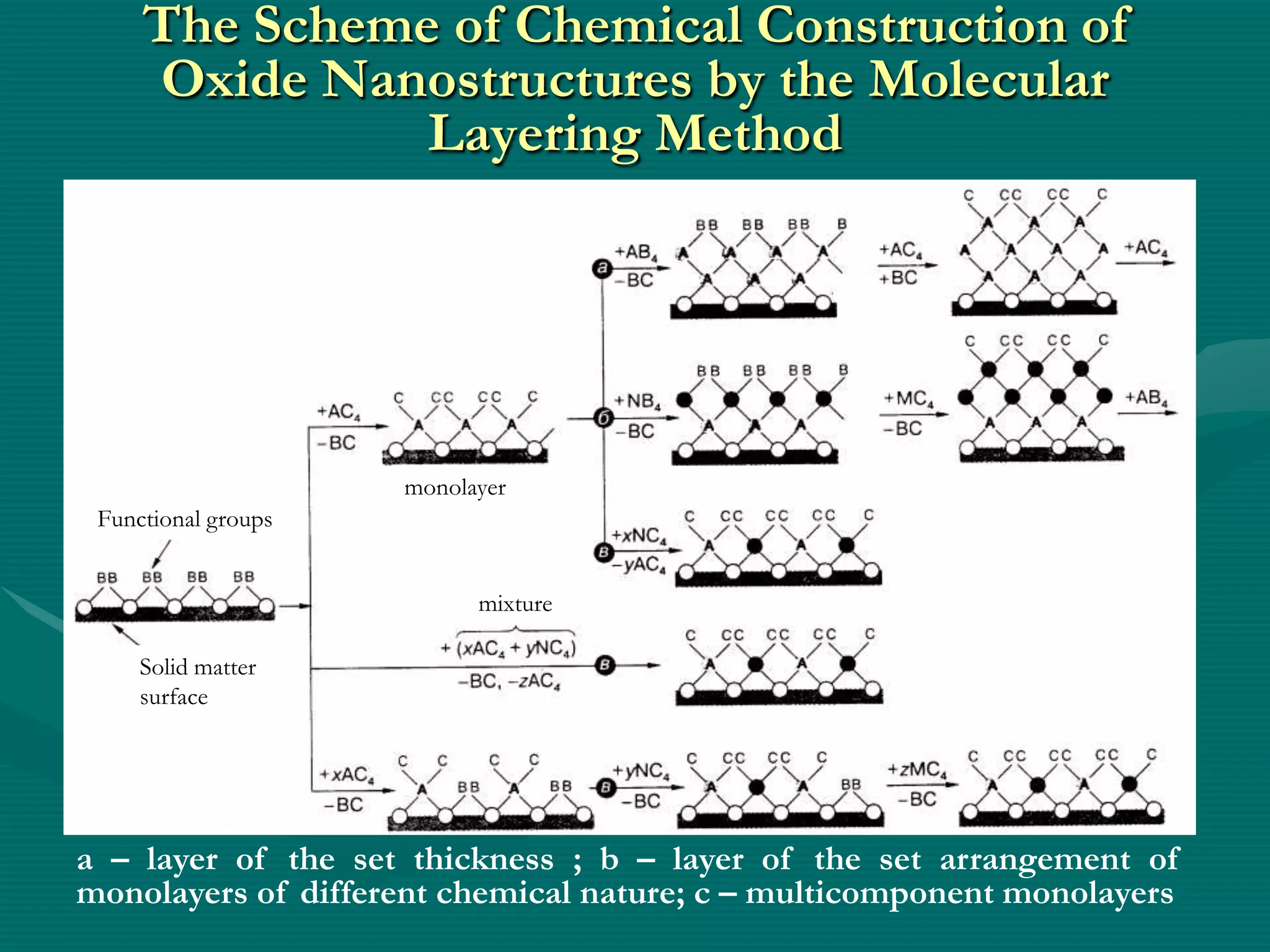

![The State of Two-Dimensional

Nanostructures on the Silica Surface

• А – with homogeneous character of distribution of

chemical composition and state, for example, monolayers

of element-oxygen groups of the same chemical

composition, l – monolayer thickness, L – layer thickness,

l1 = l2 = l3 = l4; 1– for example, Ti–O monolayers.

• B – periodic distribution of element-oxygen layers

along z axis, (L – layer thickness) consisting of the certain

quantity of monolayers, for example, according to the

scheme: 1 –Fe-O groups, 2 –Ti-O groups (a – two-layer

group, l1 = l2 , б, в – four-layer group l1 = l3 и l2 = l4 ).

• C – aperiodic distribution of element-oxygen layers

along z axis, four-layer structure l1 l2 l3 l4

• D – aperiodic distribution of atoms on the plane of

surface monolayer, top view: х –Fe-O groups, о –Ti-O

groups; а, б – different ratios of groups Fe-O and Ti-O.

• E - aperiodic distribution of “zero-dimensional"

structures on the plane of support: 1 –Si , 2 – [ Fe]](https://image.slidesharecdn.com/prezenteng-120831060857-phpapp02/75/Prezent-eng-11-2048.jpg)