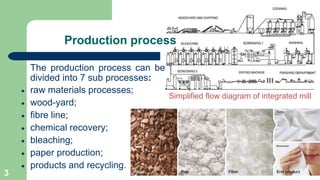

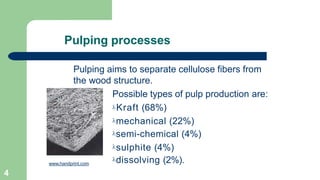

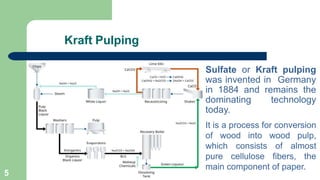

The document discusses the pulp and paper industry, detailing its production processes, environmental challenges, and the issue of pitch deposits that complicate operations. It outlines traditional and enzymatic methods to control pitch problems, highlighting the environmental impacts of pulp mills and advocating for cleaner production practices. The conclusion emphasizes the need for sustainable methods and the importance of reducing waste and toxicity in the industry.

![• Enzymatic pitch control:

• Hydrolytic enzymes- Lipases

• Oxidative enzymes- Oxidoreductases

(laccases- 2,2′-azinobis(3-

ethylbenzothiazoline- 6-sulphonic acid

[ABTS], 1-hydroxybenzotriazole [HBT] ),

lipoxygenases.

3. soft-rot, and

4. sap stain (Ophiostoma, Ceratocystis,

Leptographium) species

11](https://image.slidesharecdn.com/solvingpitchproblem-210518055817/85/Solving-pitch-problem-11-320.jpg)