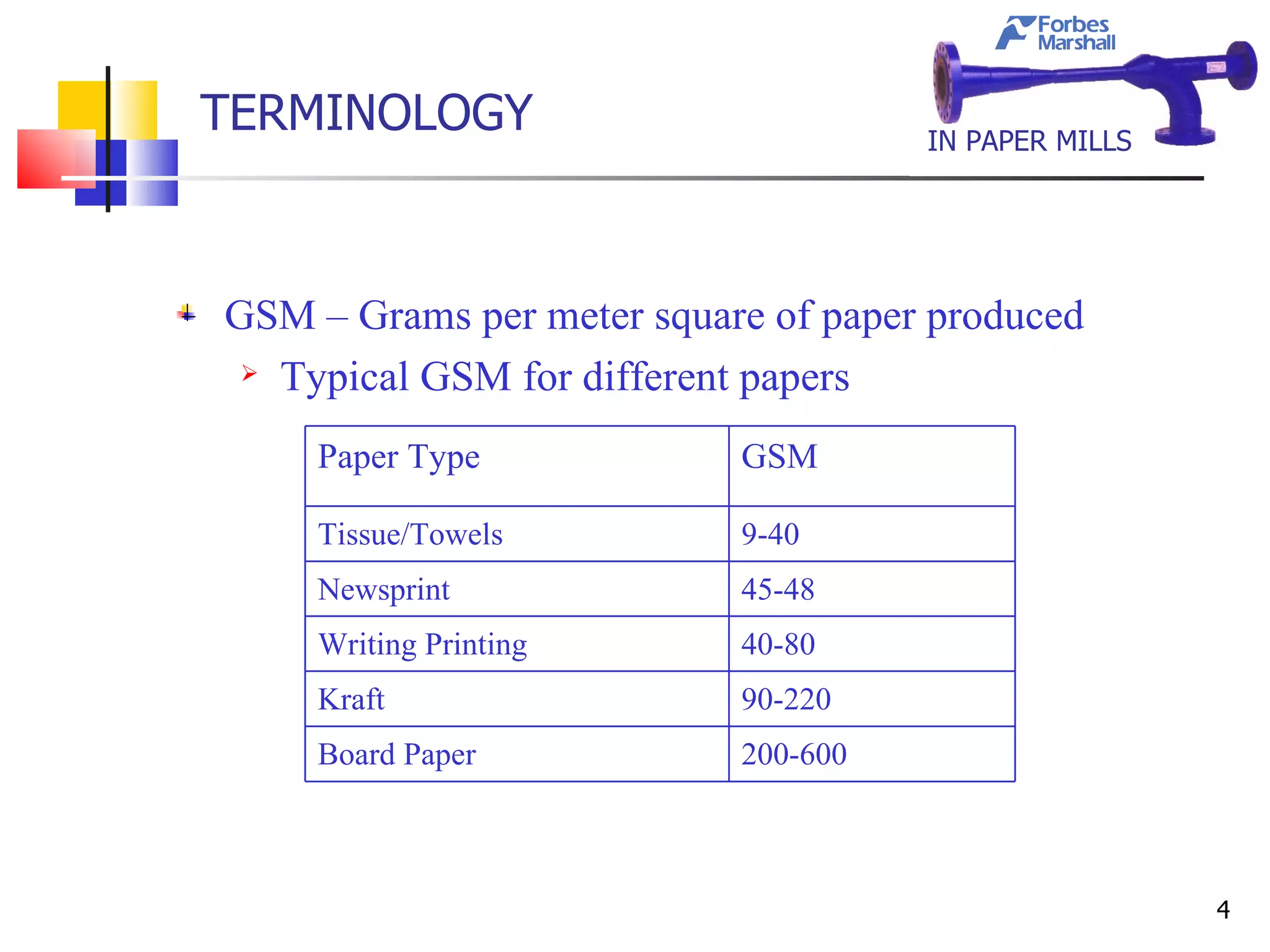

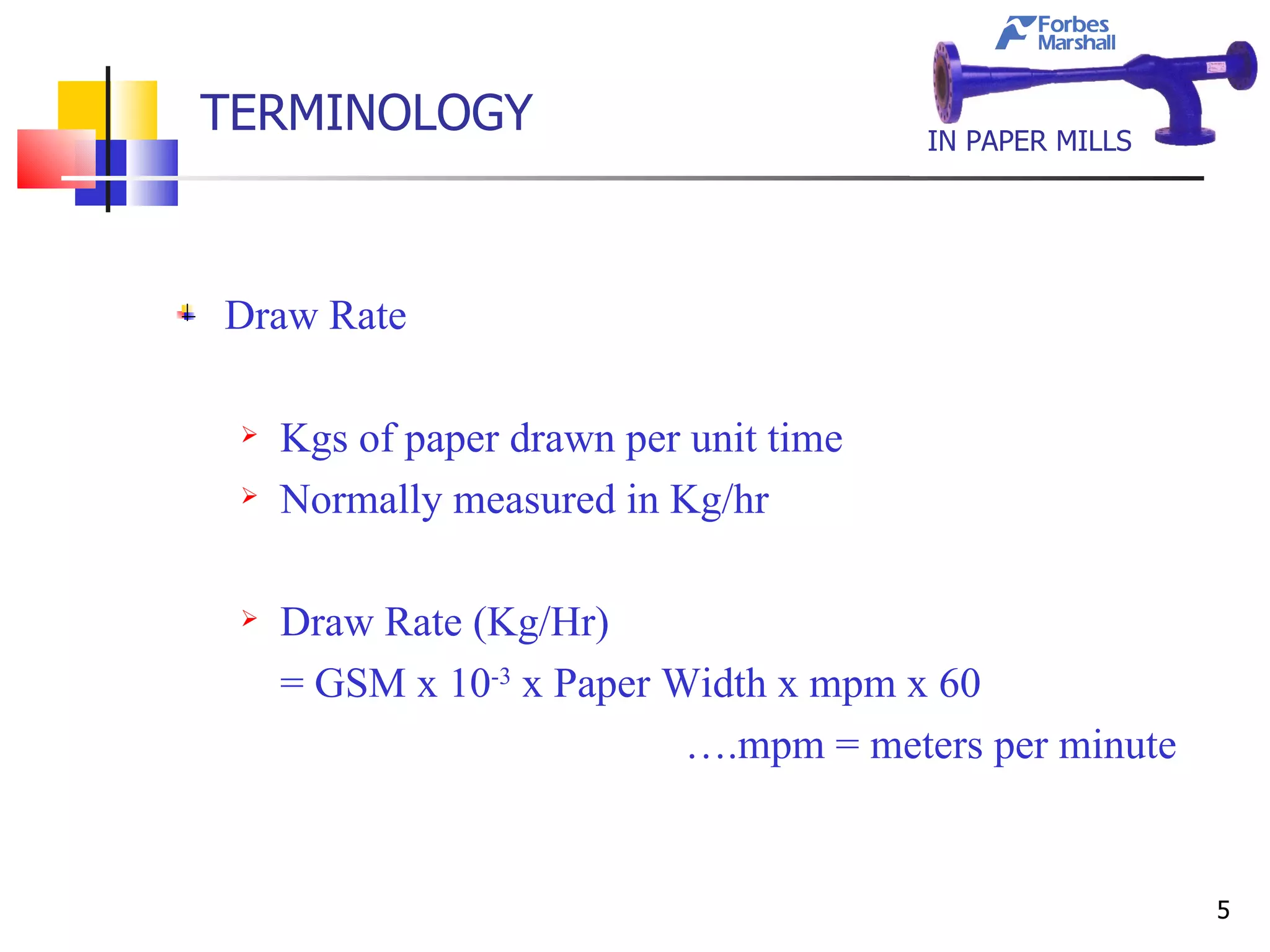

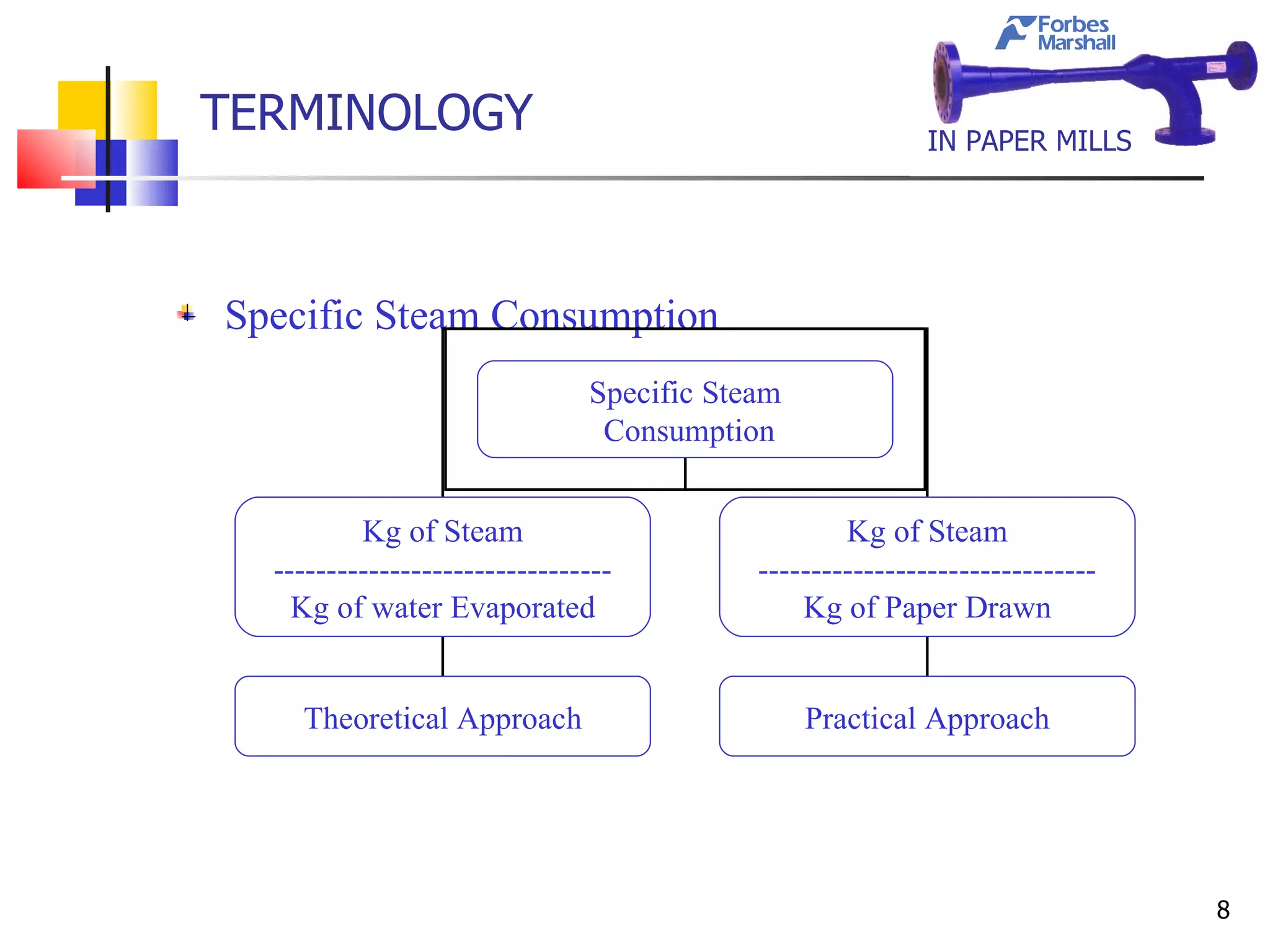

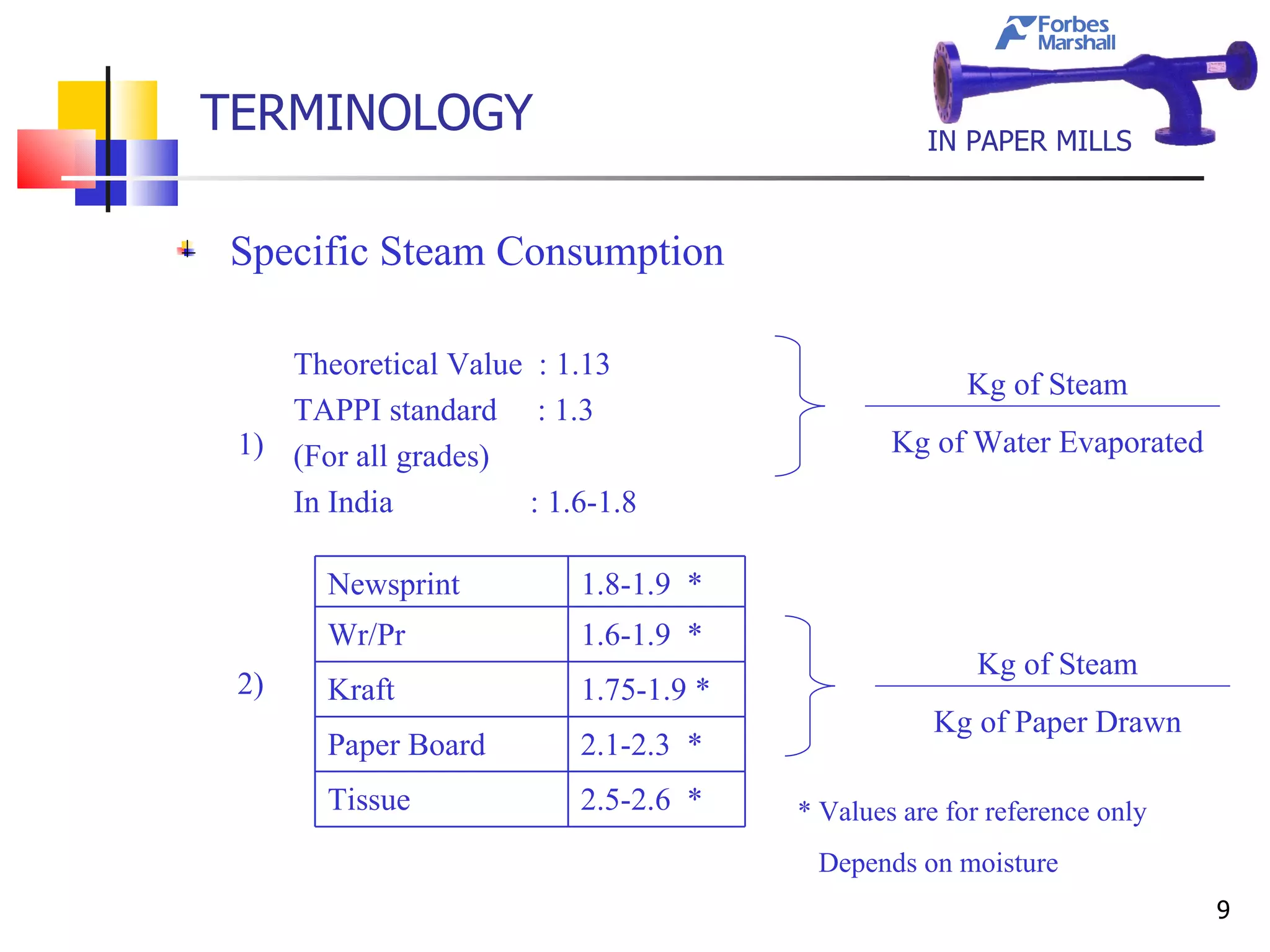

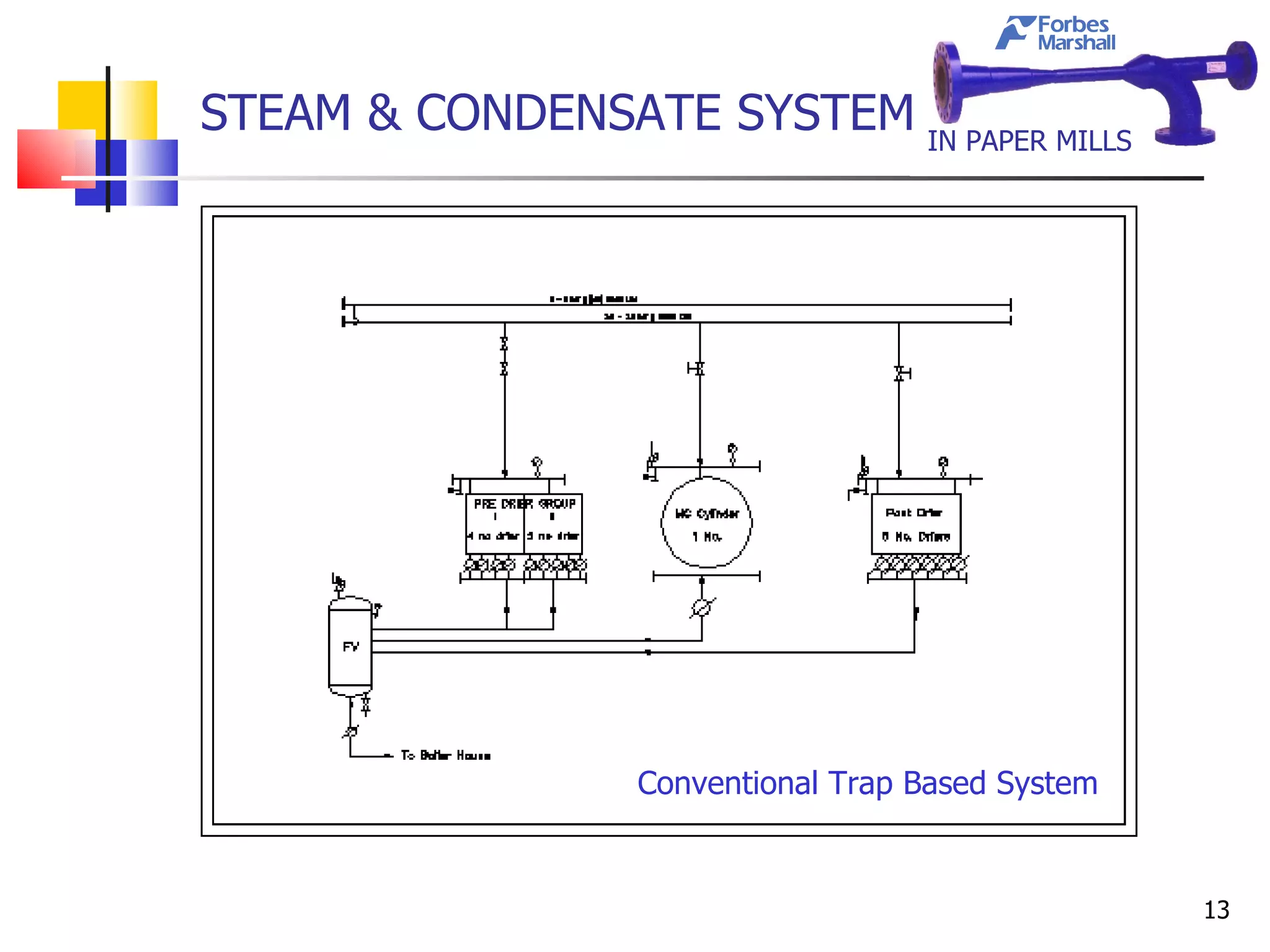

The document discusses steam and condensate systems used in paper mills. It describes different types of paper mills based on raw materials and classifications. It also defines key terminology used in paper mills like GSM, draw rate, drying rate and specific steam consumption. The document discusses three main types of condensate evacuation systems - conventional trap based, cascade and thermocompressor based blow-through systems. It also describes rotary joints, syphons and factors in selecting appropriate steam and condensate systems based on machine speed.