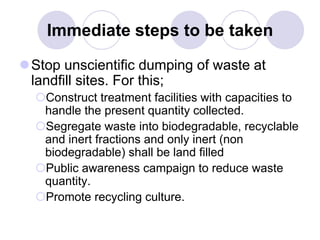

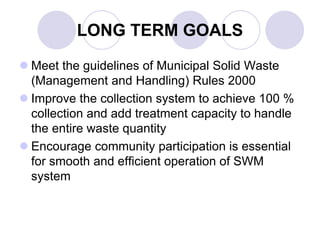

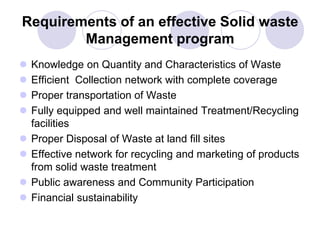

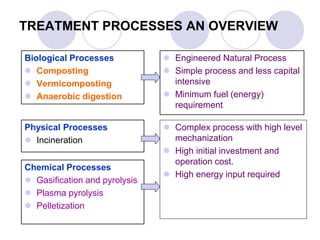

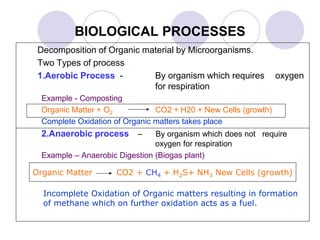

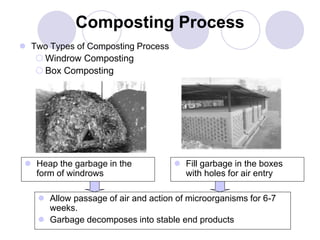

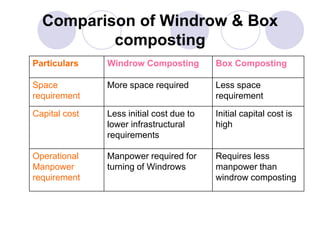

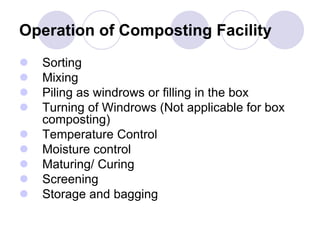

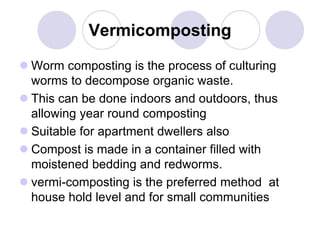

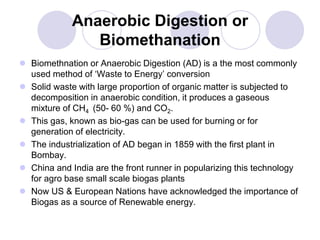

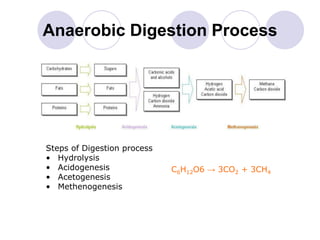

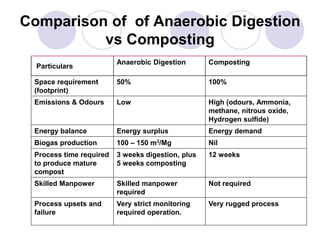

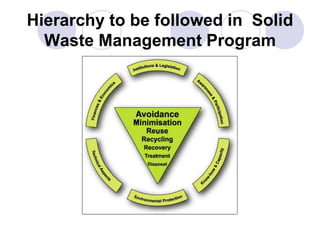

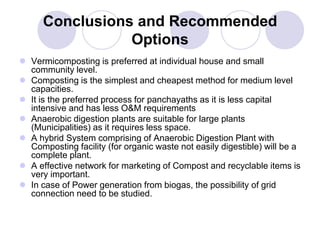

This document discusses solid waste management issues in India. It notes that rapid urbanization, neglect by authorities, and public apathy have led to a garbage crisis. To address this, authorities must implement proper waste management systems as per regulations by treating waste via composting, anaerobic digestion, or other technologies. The document outlines several waste treatment options and recommends that vermicomposting is suitable for individual homes, composting is best for medium capacities, and anaerobic digestion is appropriate for large volumes of waste. Effective waste management requires proper collection, transportation, treatment, disposal and public awareness.