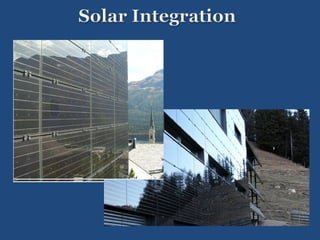

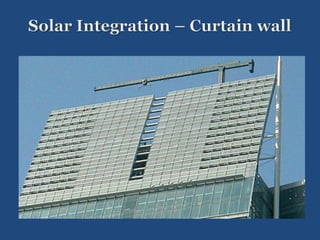

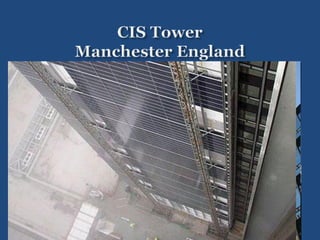

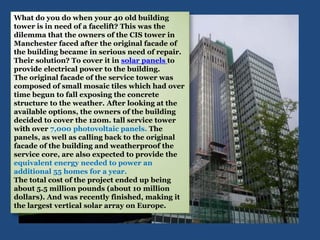

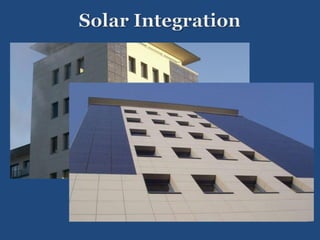

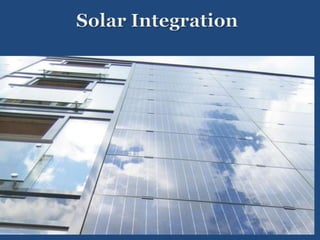

The document discusses solar integration with building design. It provides examples of how solar panels were used to renovate the facade of a 40-year-old tower in Manchester, creating the largest vertical solar array in Europe. The solar panels generated enough power for 55 homes annually while weatherproofing and updating the building. The document argues that sustainable design should integrate trades like rainscreen technology and solar power. Specifiers need to work with architects and owners to specify these integrated solar and energy-efficient systems.