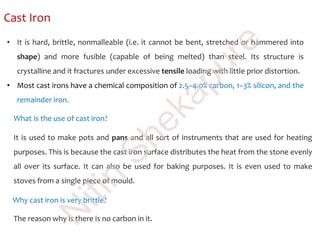

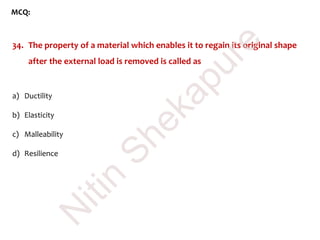

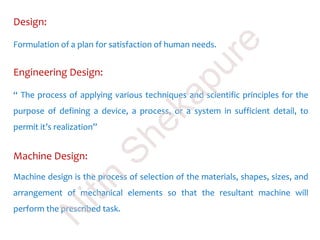

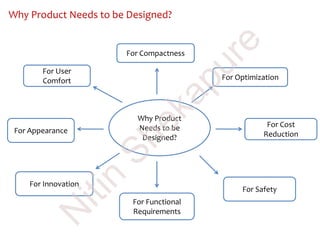

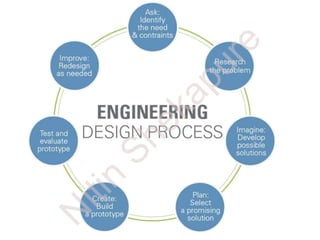

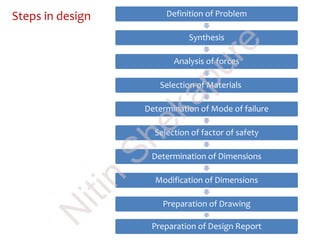

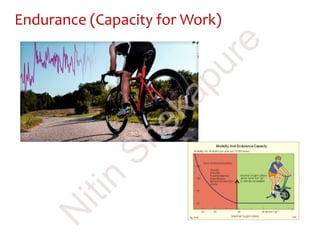

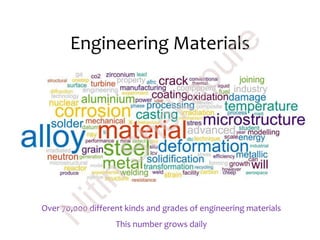

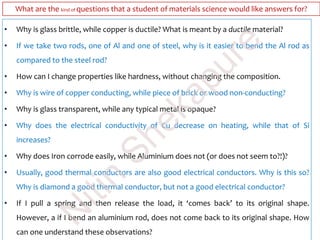

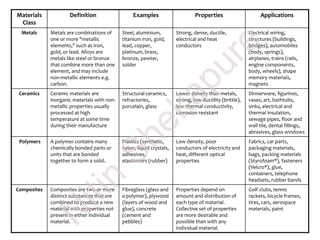

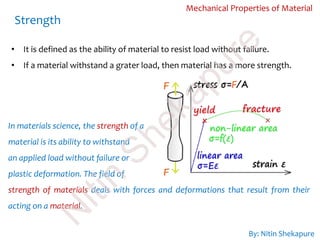

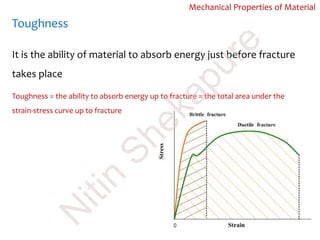

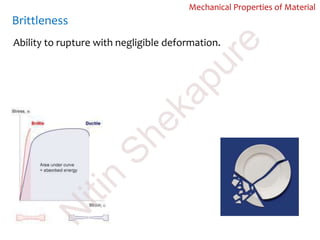

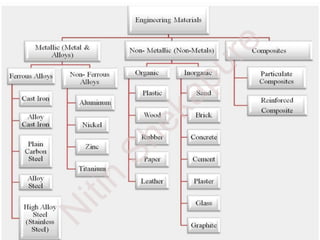

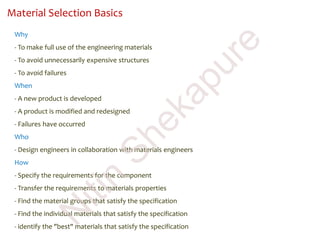

The document covers the fundamentals of mechanical engineering design, detailing the design process, materials selection, and mechanical properties such as strength, toughness, and elasticity. It emphasizes the importance of ergonomics and user comfort in design, as well as the need to satisfy human needs through innovative product development. Additionally, it discusses various types of materials—metals, ceramics, polymers, and composites—and their mechanical properties, providing a comprehensive overview of design principles in engineering.

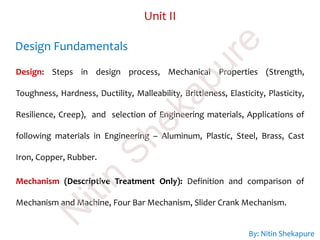

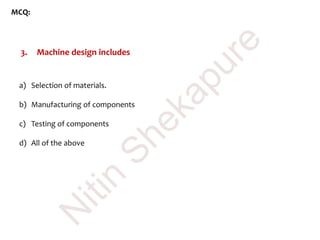

![Material Selection Criteria

Criteria

Availability The material should be already available in the market in the abundant

quantity.

Cost The cost of the material selected for a particular job from several

alternatives should be minimum.

Material

Properties

The properties of the materials selected should meet the functional

requirements and the service conditions.

Manufacturing

Considerations

It has been the most important factor while selecting the material for a

particular job. The materials should be selected for particular part

based on the process by which it is going to be manufactured.

Environmental

Considerations

The effect of environmental conditions [Like temperature, humidity,

etc.] should be given more attention during selection of material.

Machinability

Machinability is the case with which a given metal can be machined.

Machinability of the material depends upon hardness, strength and

chemical Composition of materials.

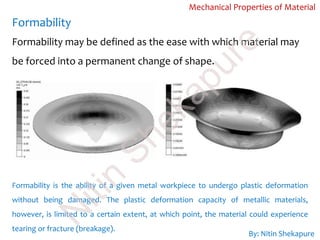

Formability

It is an indication of suitability of the metal for a machine part that

requires forming. Forming depends upon ductility and tensile Strength.

N

itin

Shekapure](https://image.slidesharecdn.com/bmeunitiibynitinshekapure-191002024546/85/Design-Fundamentals-84-320.jpg)