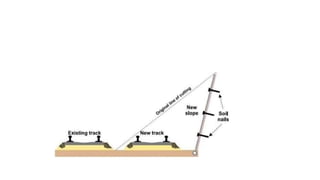

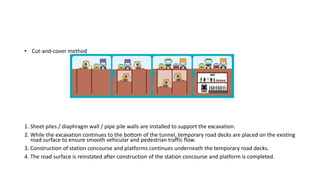

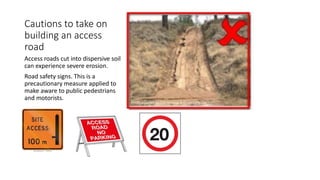

Soil retention is important for plant growth, flood control, and soil functioning. Soil texture and composition determine water retention levels, with sandy soils retaining the least and clay soils retaining the most. Soil can hold considerable amounts of water important for plants and organisms. The maximum water soil can hold is field capacity, while the minimum for plant growth is wilting point. Soil water retention impacts the environment, climate, hydrological cycle, and soil stability. Techniques to retain soil include soil nailing, retaining walls, and different types of excavation methods.