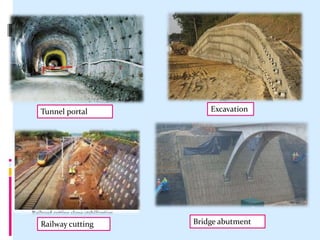

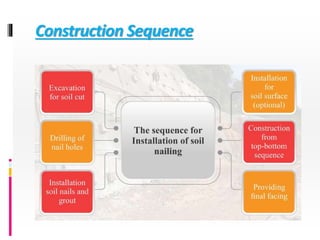

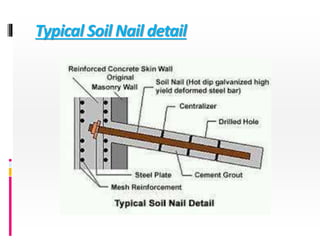

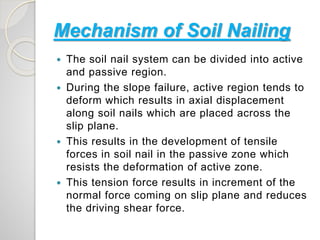

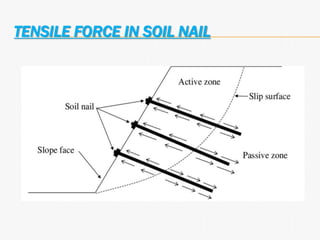

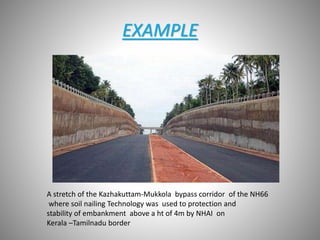

This document provides an overview of soil nailing techniques. It discusses that soil nailing involves drilling holes in slopes and inserting steel bars that are grouted in place to reinforce and stabilize the slope. It then covers the origins of soil nailing, common applications, advantages, limitations, construction sequence, mechanisms, and methods such as drilled and grouted, driven, and self-drilling nails. An example of a soil nailing project in India is also described before concluding with benefits such as being economical and applicable in seismic zones.