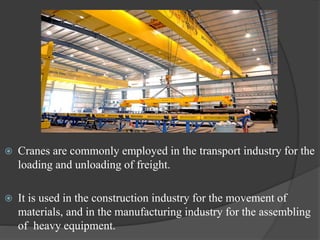

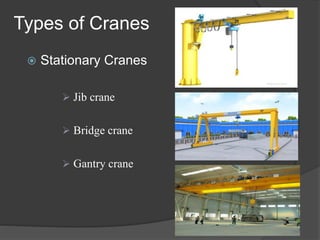

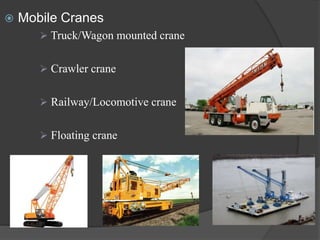

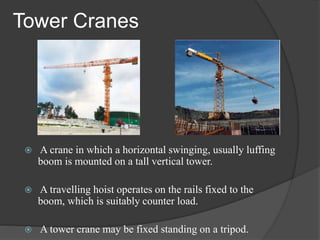

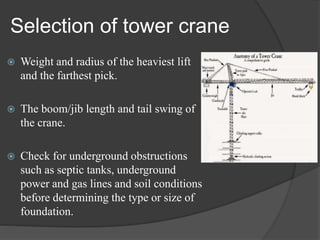

A crane is a machine that uses simple machines and hoists to lift and move heavy loads beyond human capability. Cranes are commonly used to load and unload freight in transport, and to assemble heavy equipment and move materials in construction and manufacturing. There are several types of cranes including stationary cranes like jib, bridge, and gantry cranes, stationary revolving cranes like wharf and pillar cranes, and mobile cranes like truck-mounted, crawler, railway, and floating cranes. Tower cranes in particular are mounted on a tall vertical tower and use a horizontal swinging boom to lift loads, making them well-suited for construction of tall buildings. Proper maintenance like cleaning, lubricating,