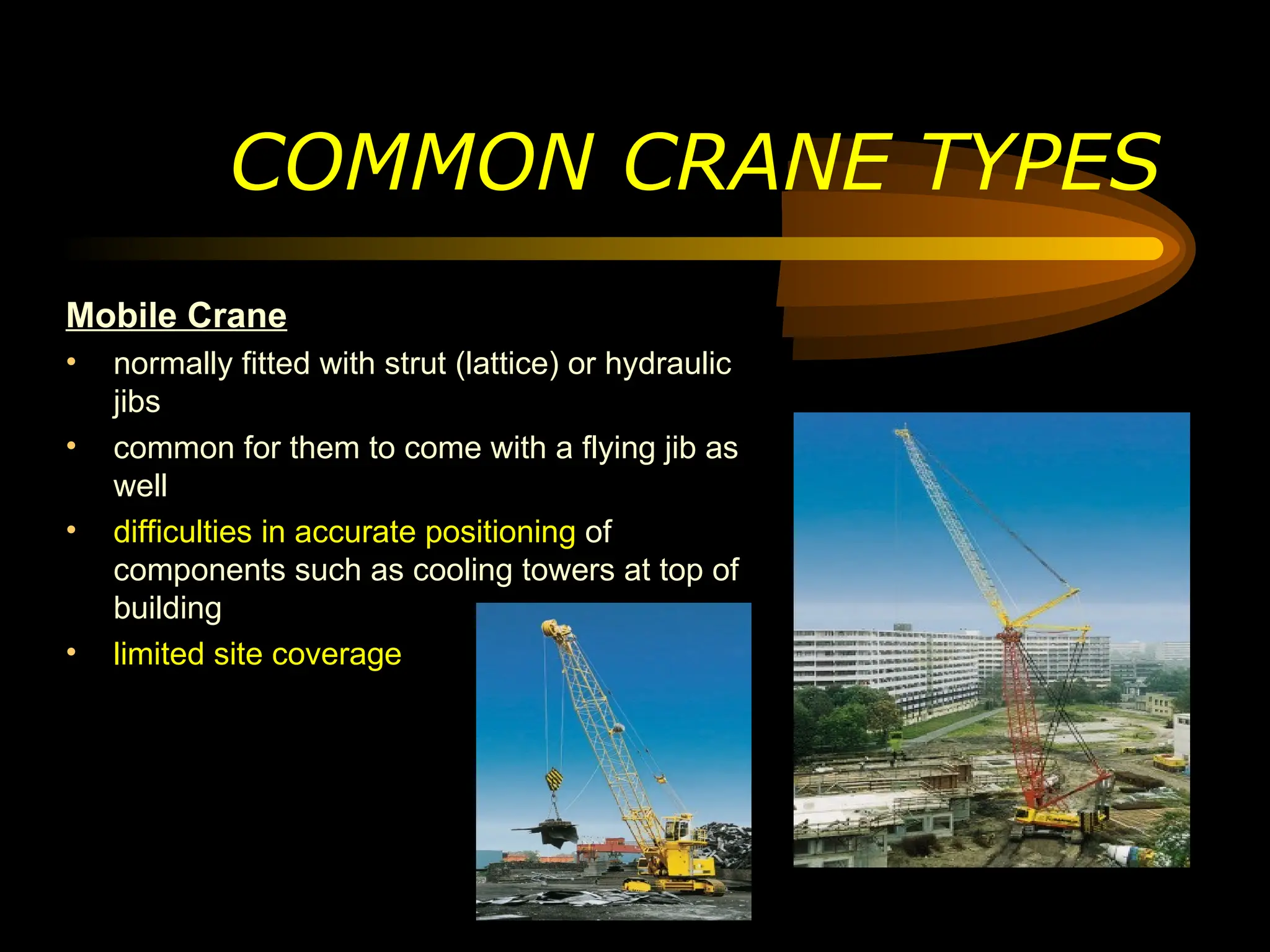

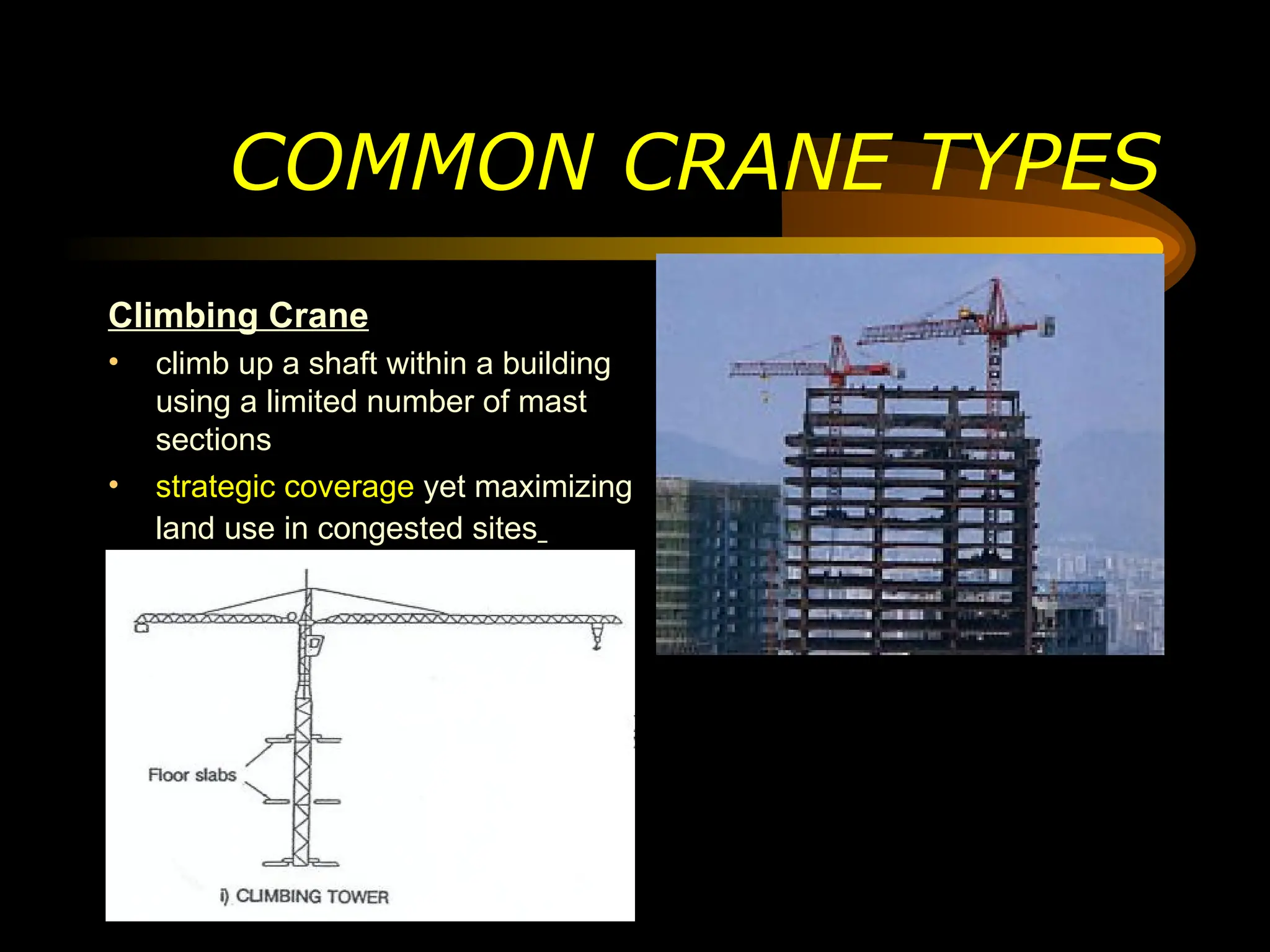

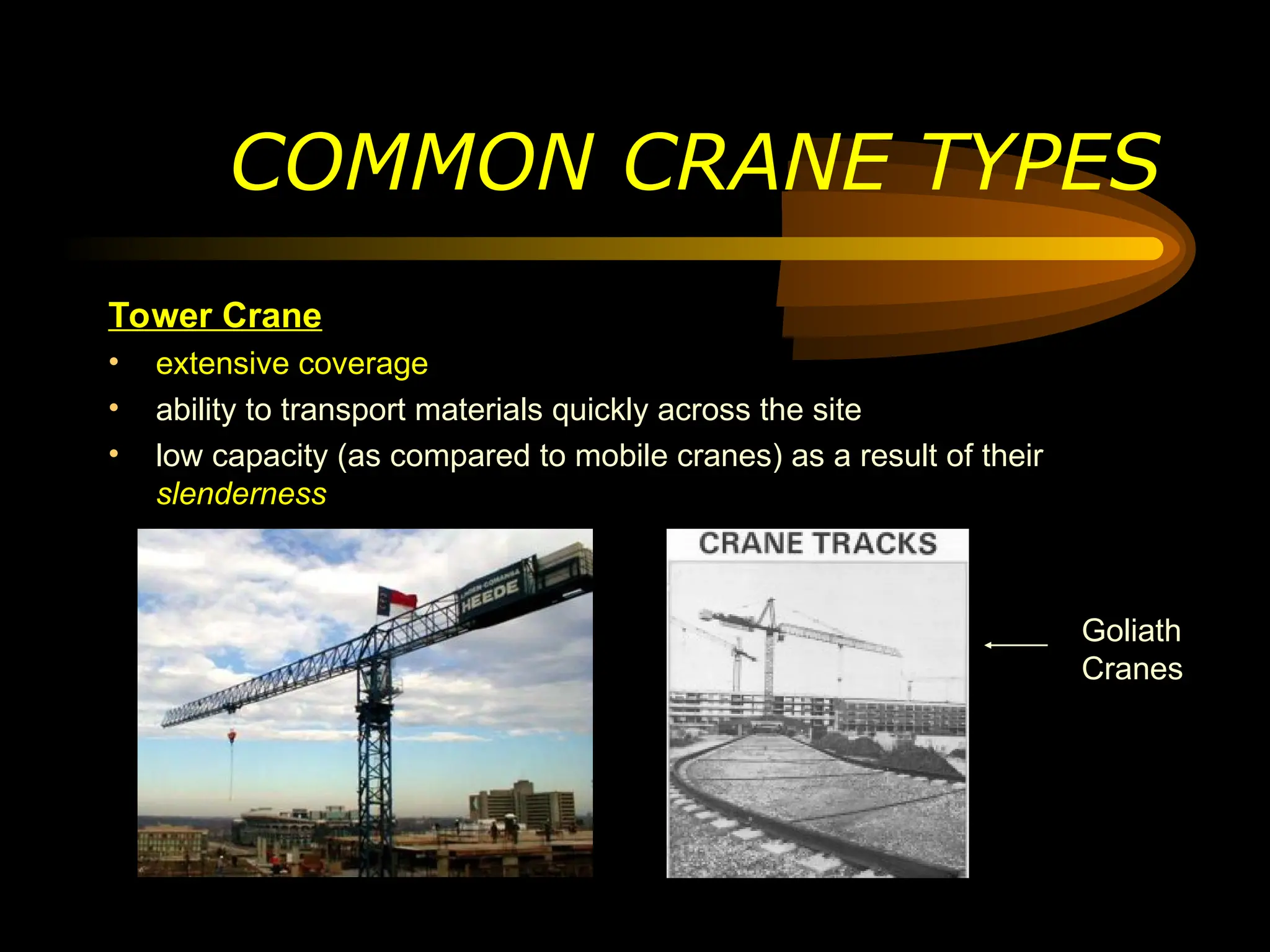

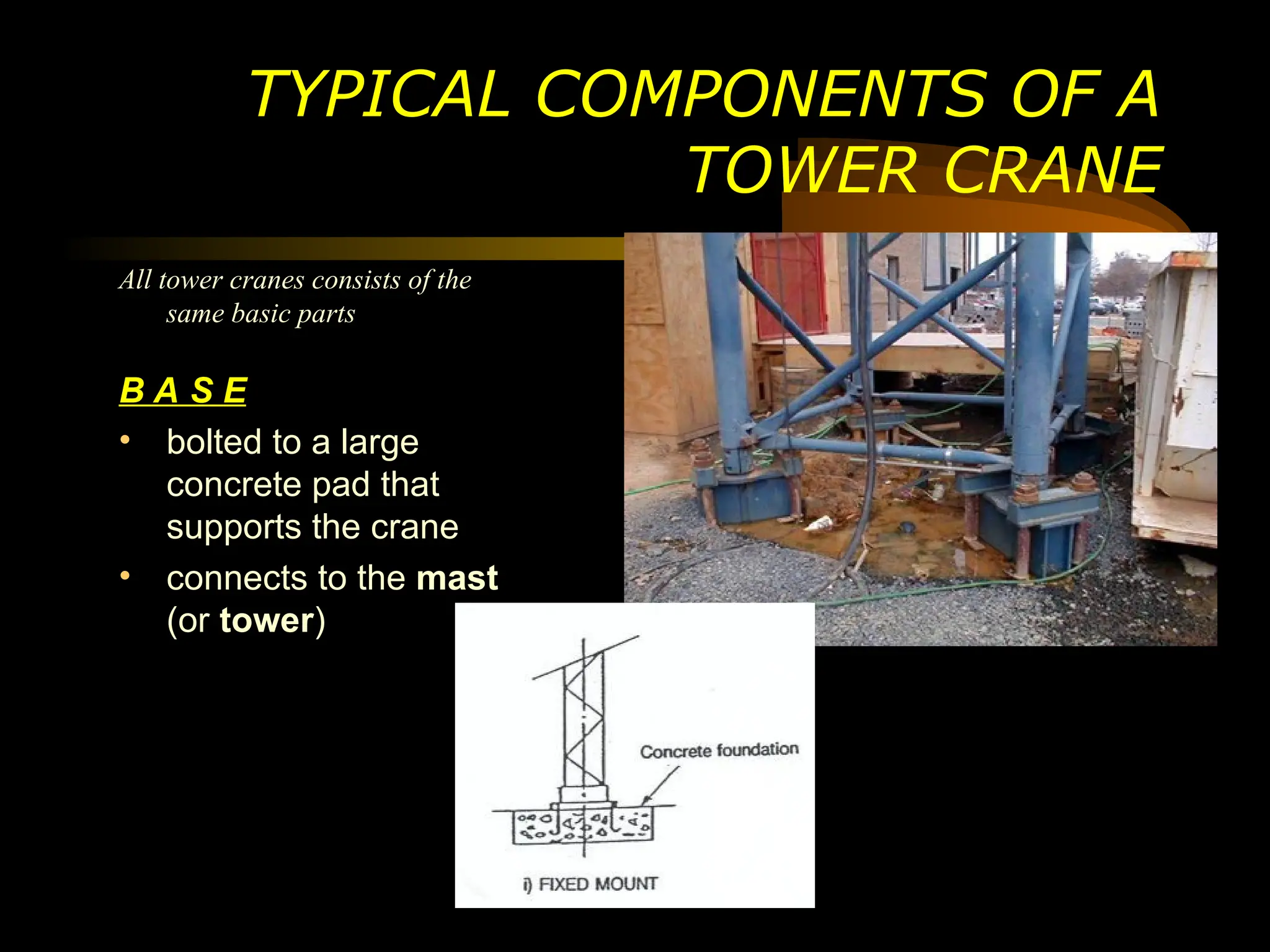

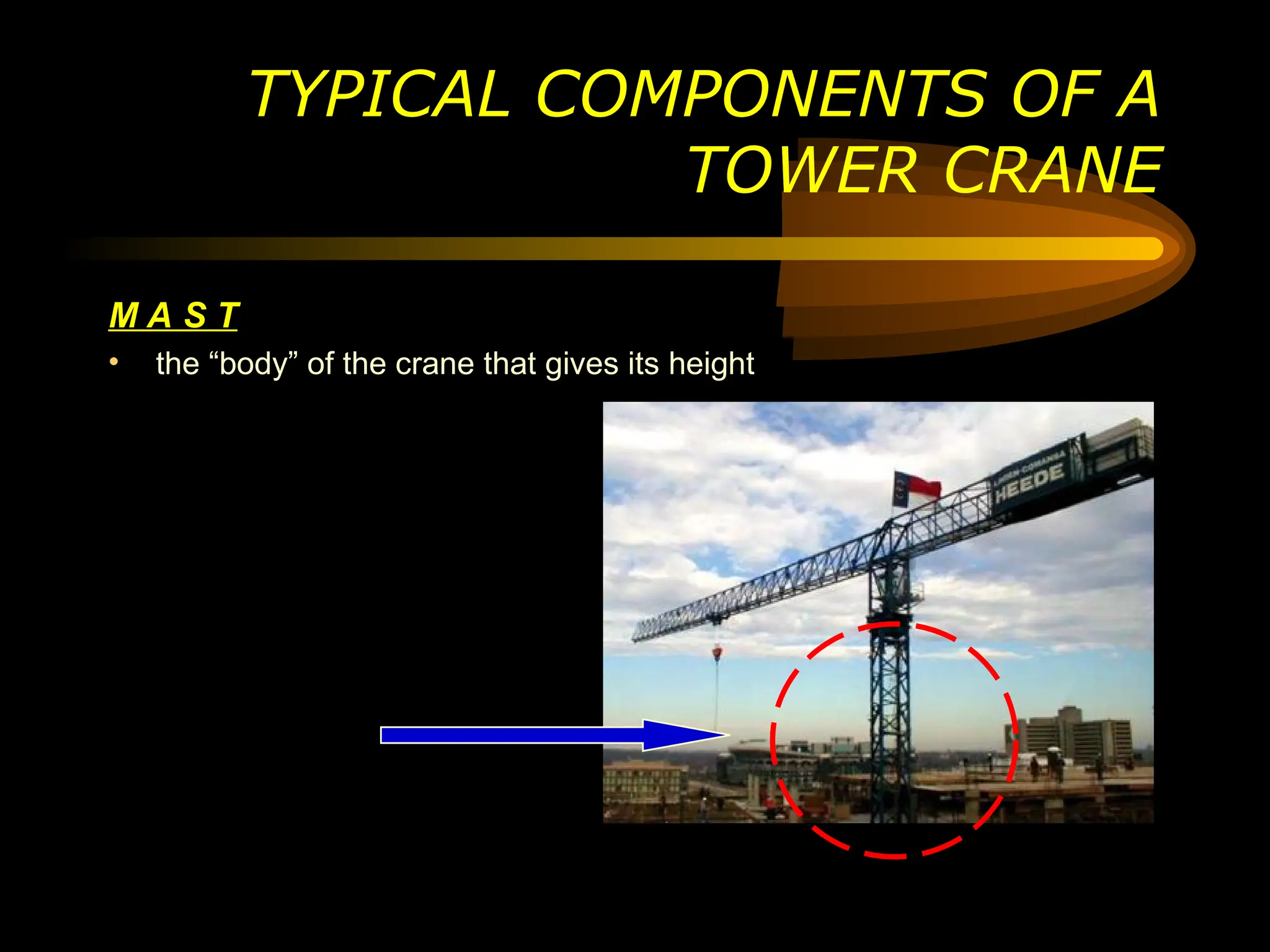

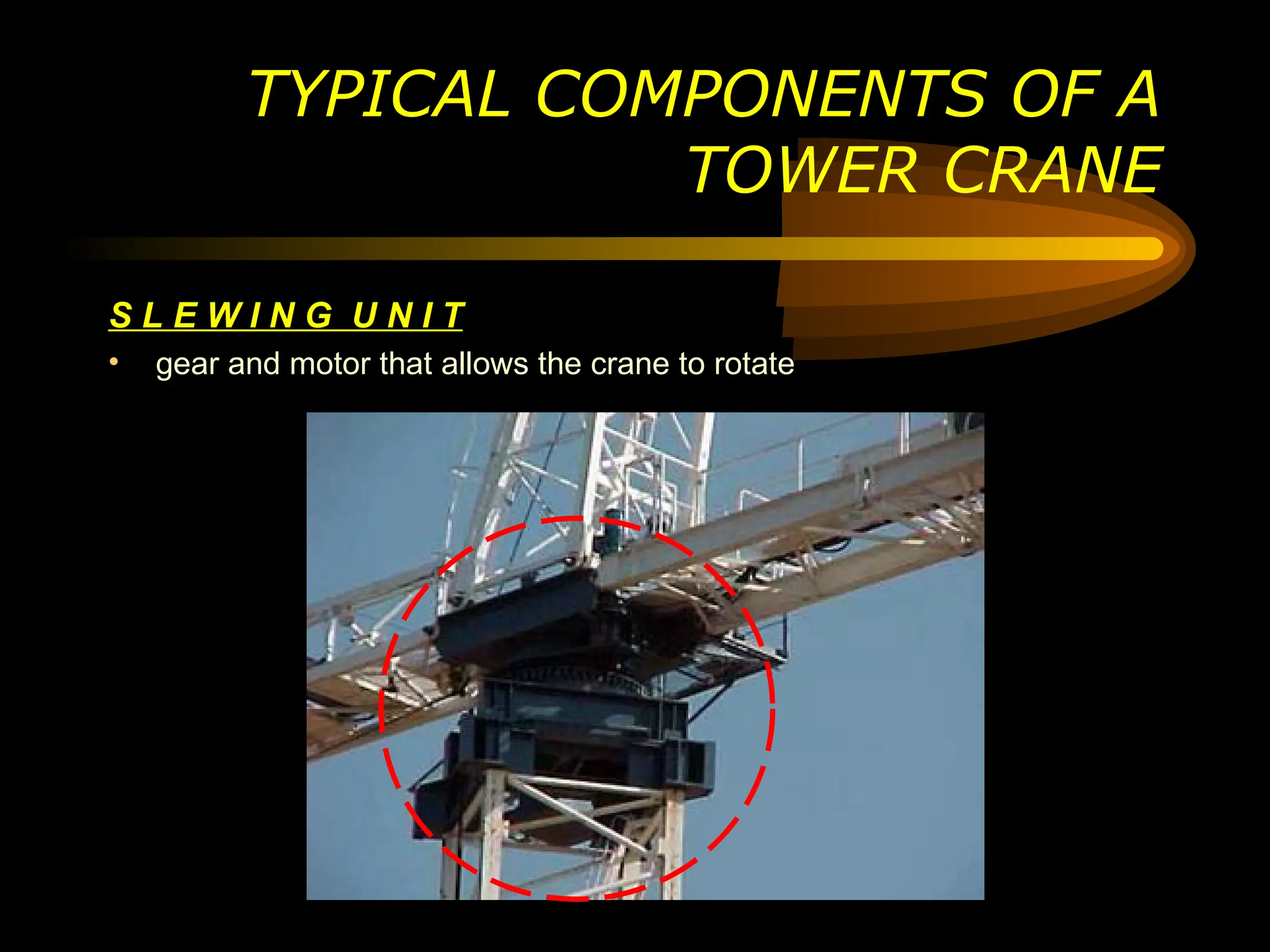

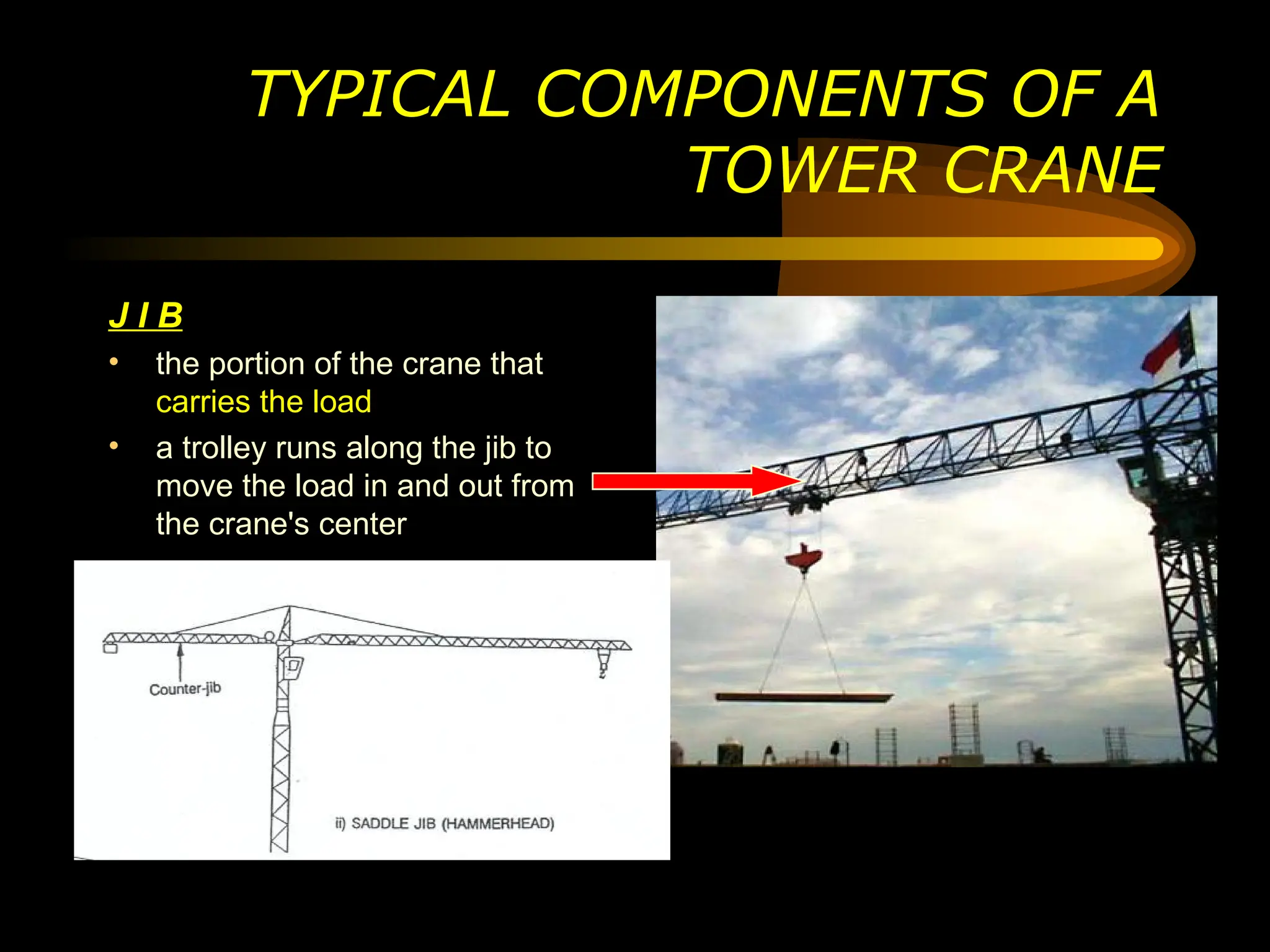

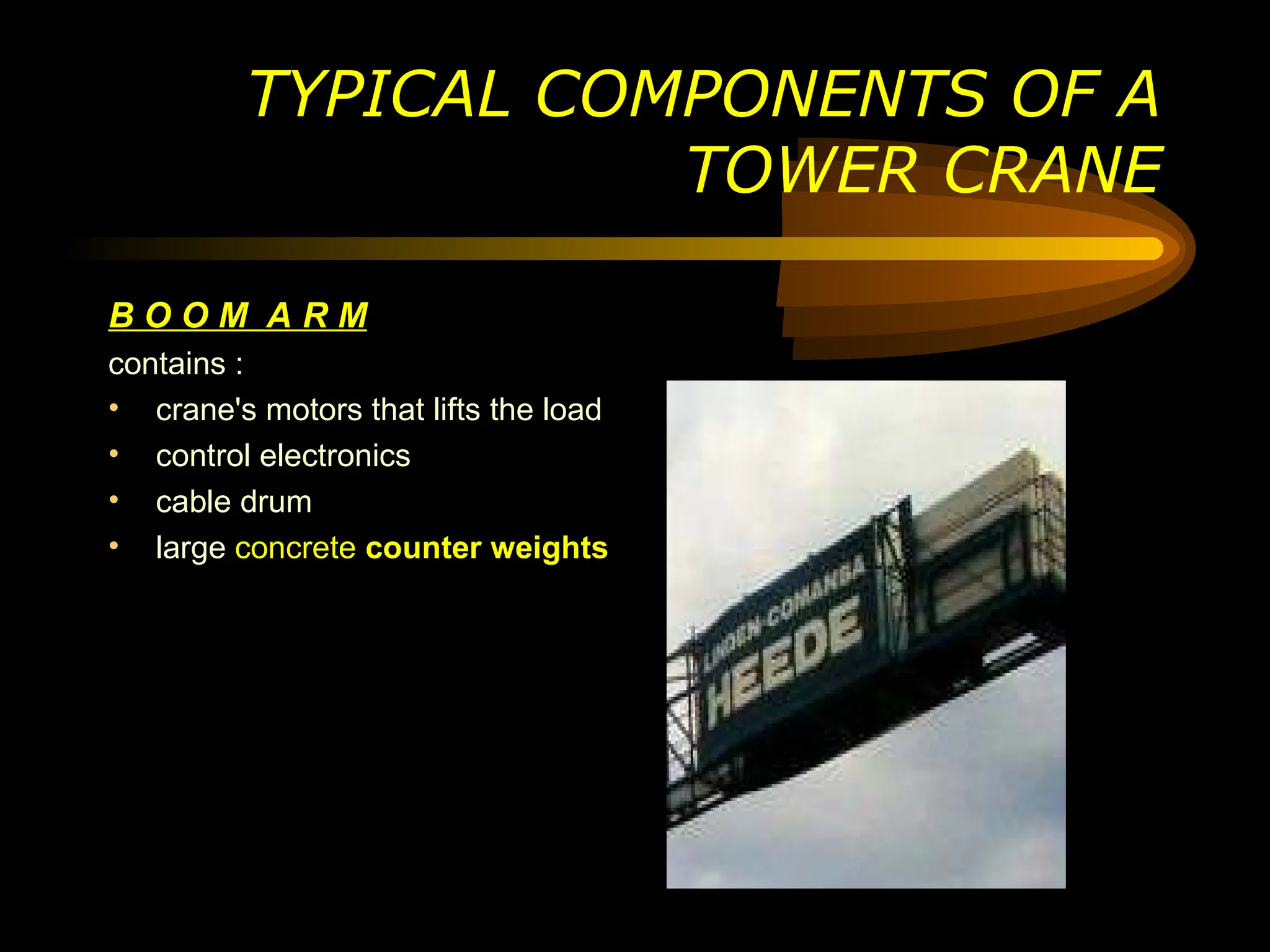

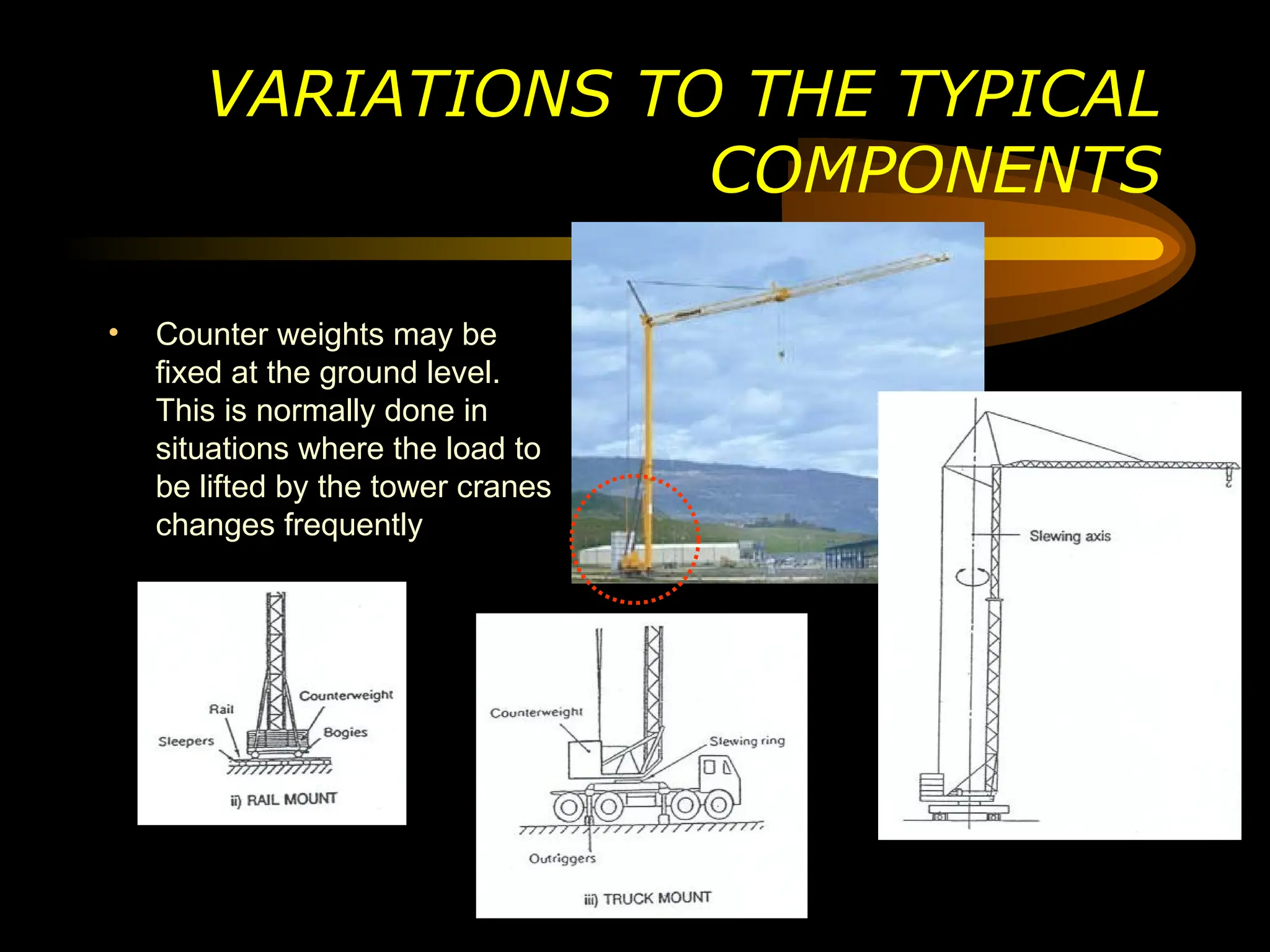

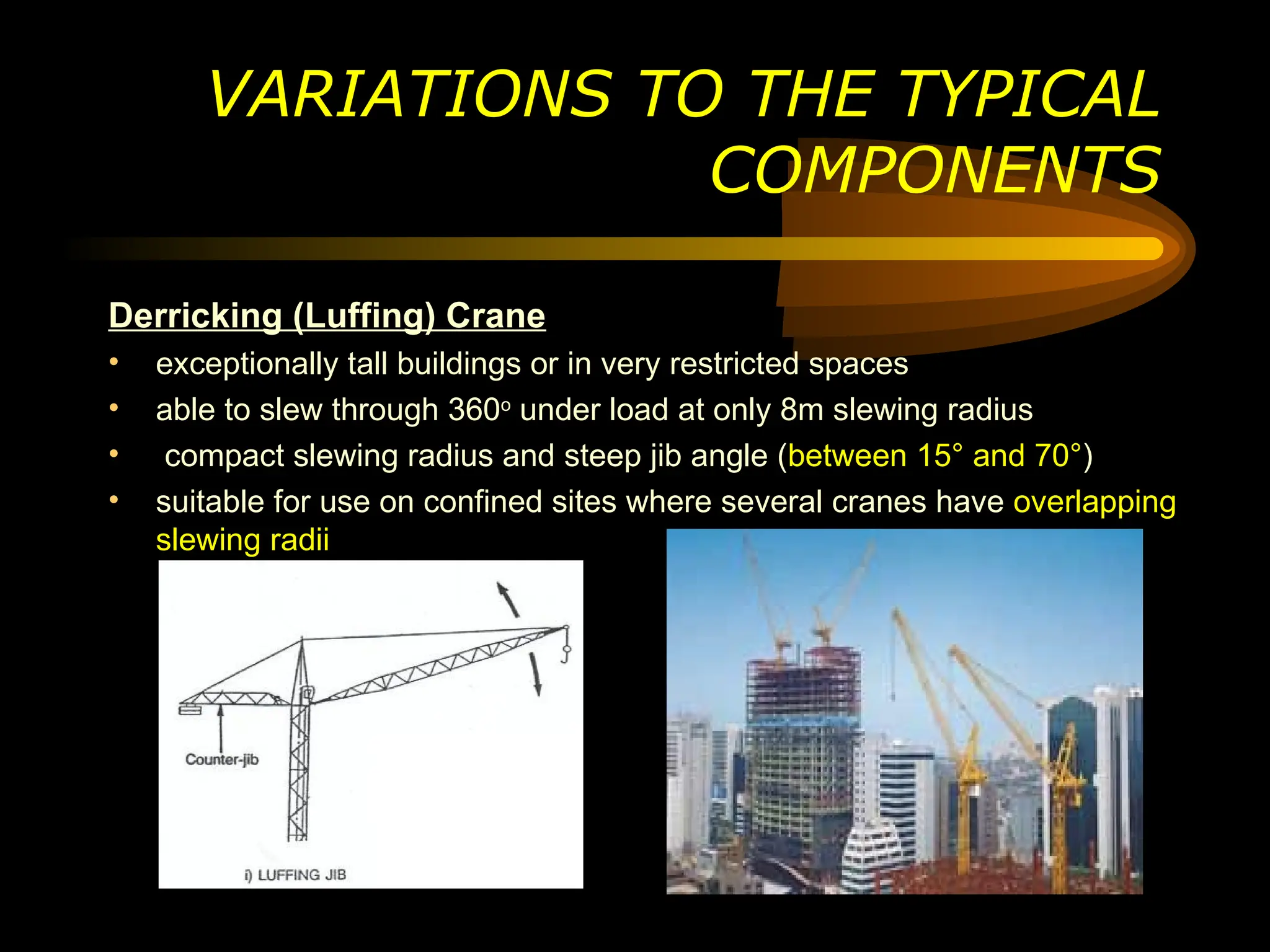

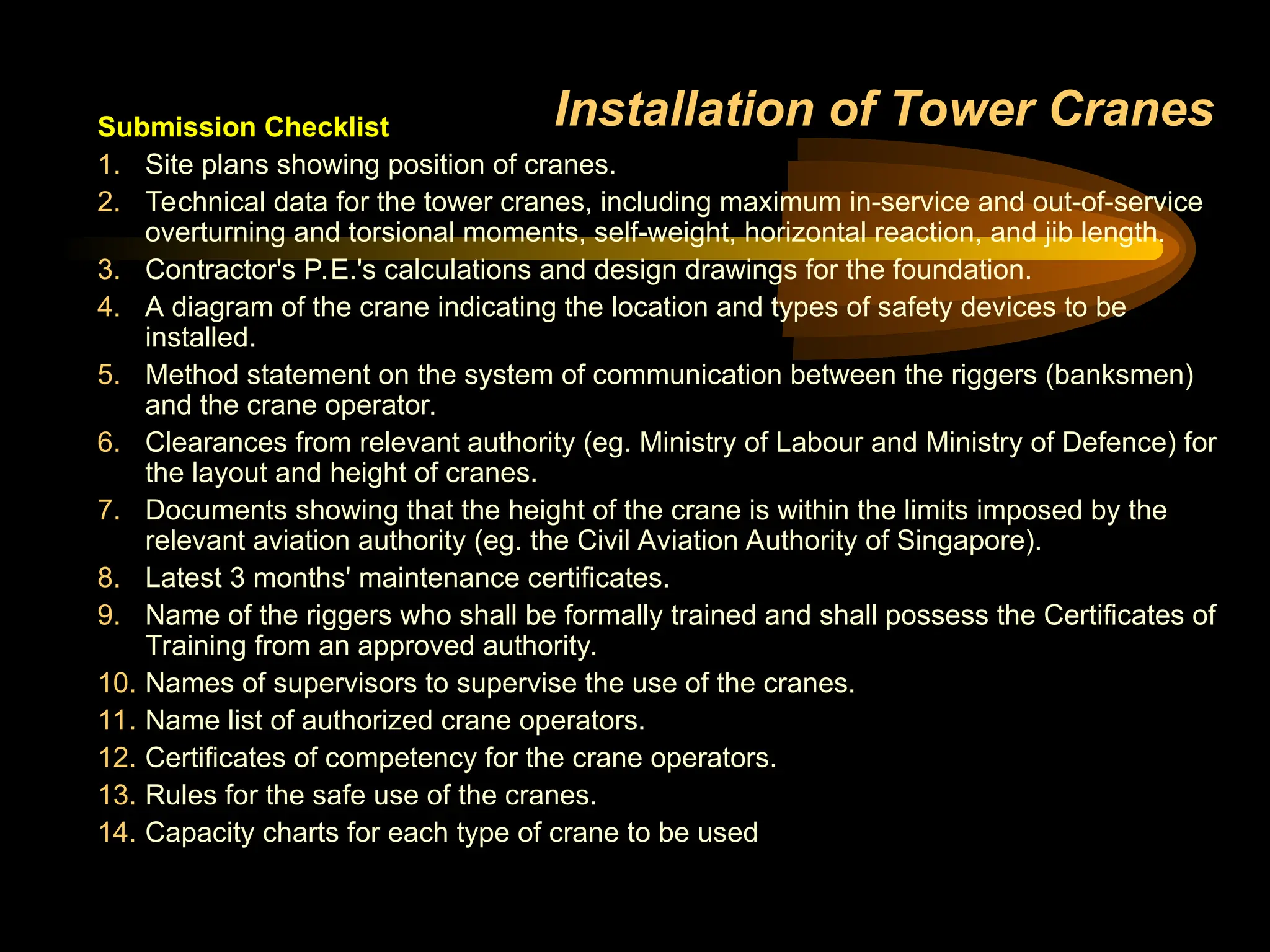

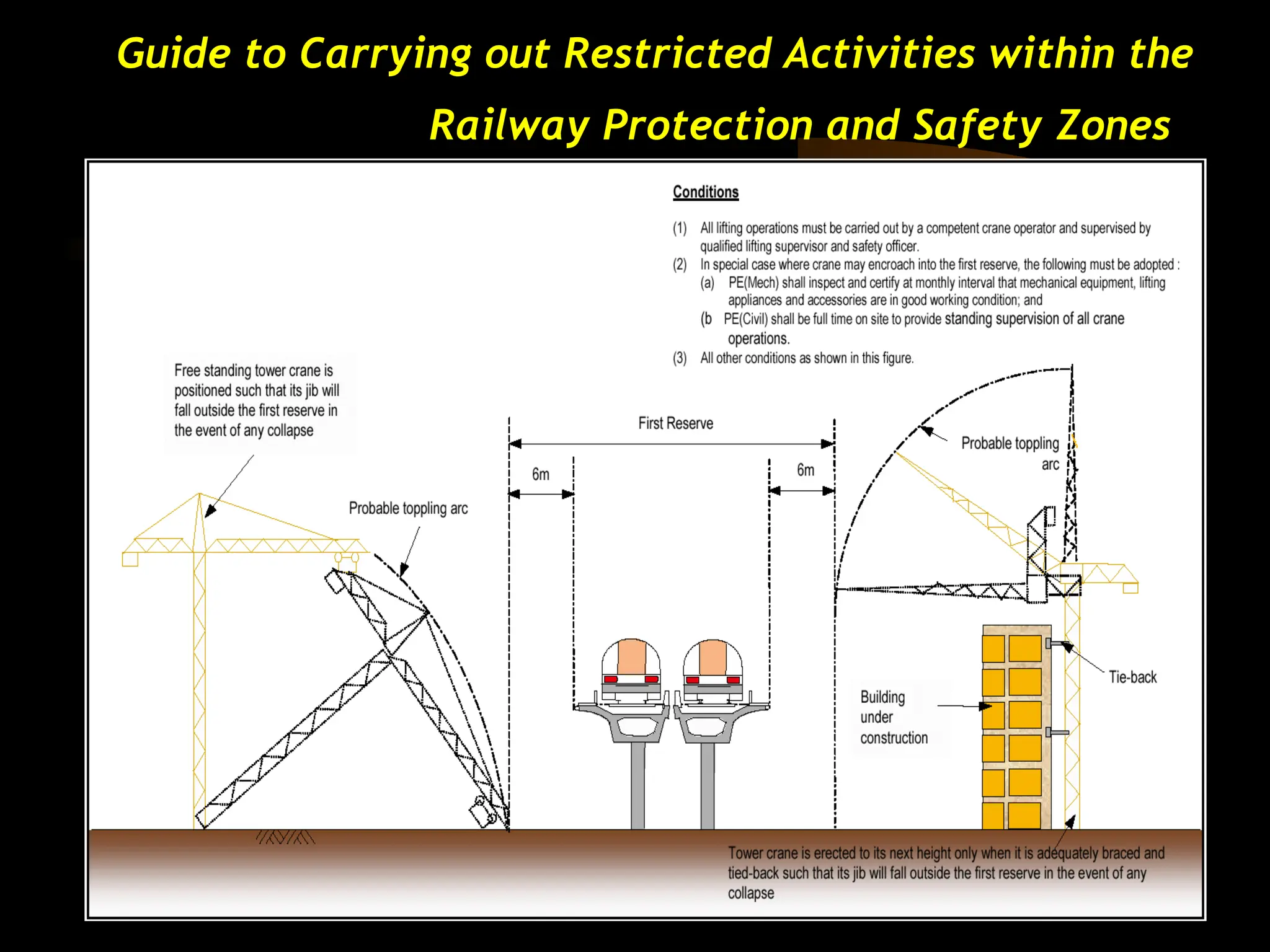

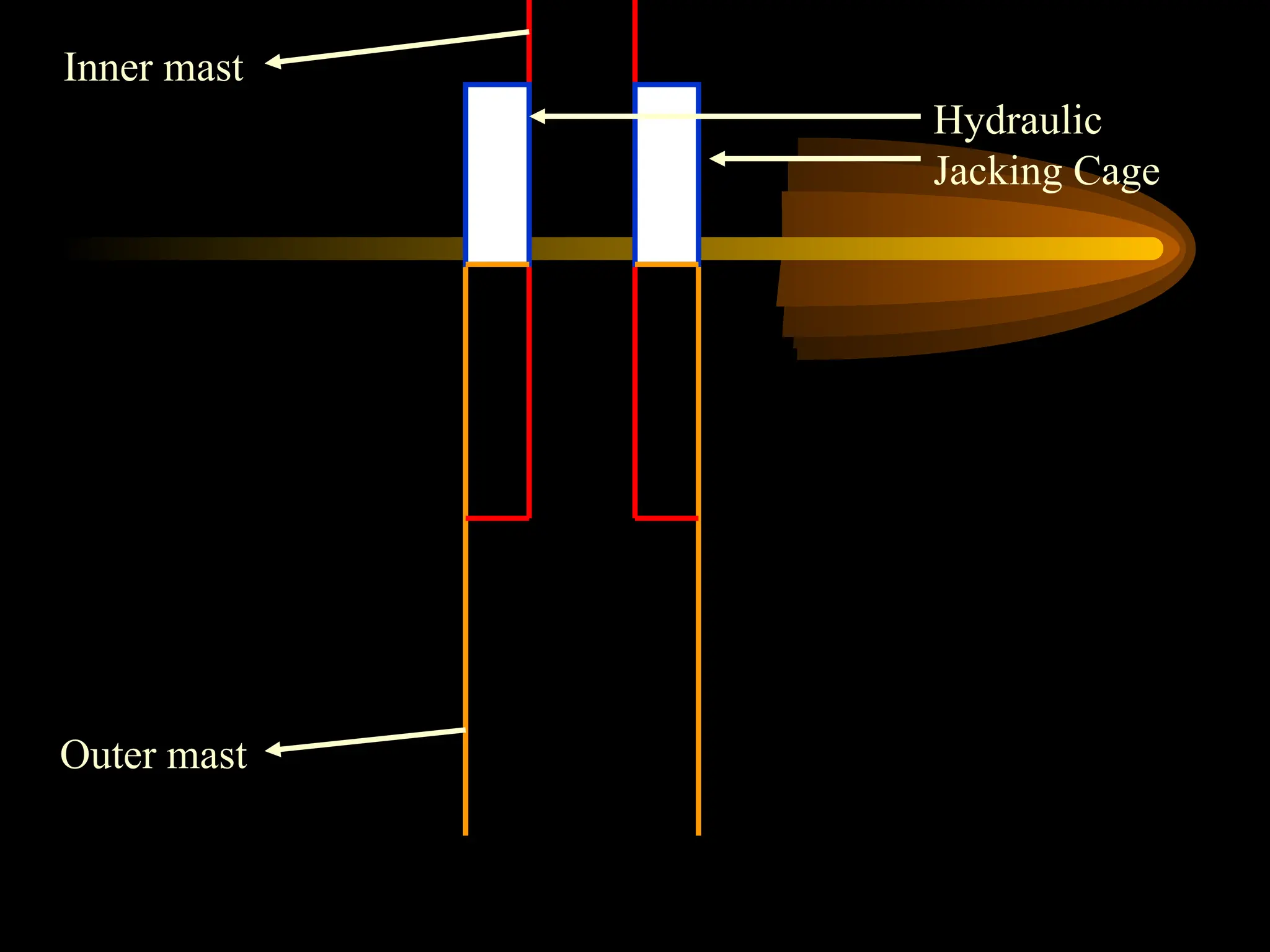

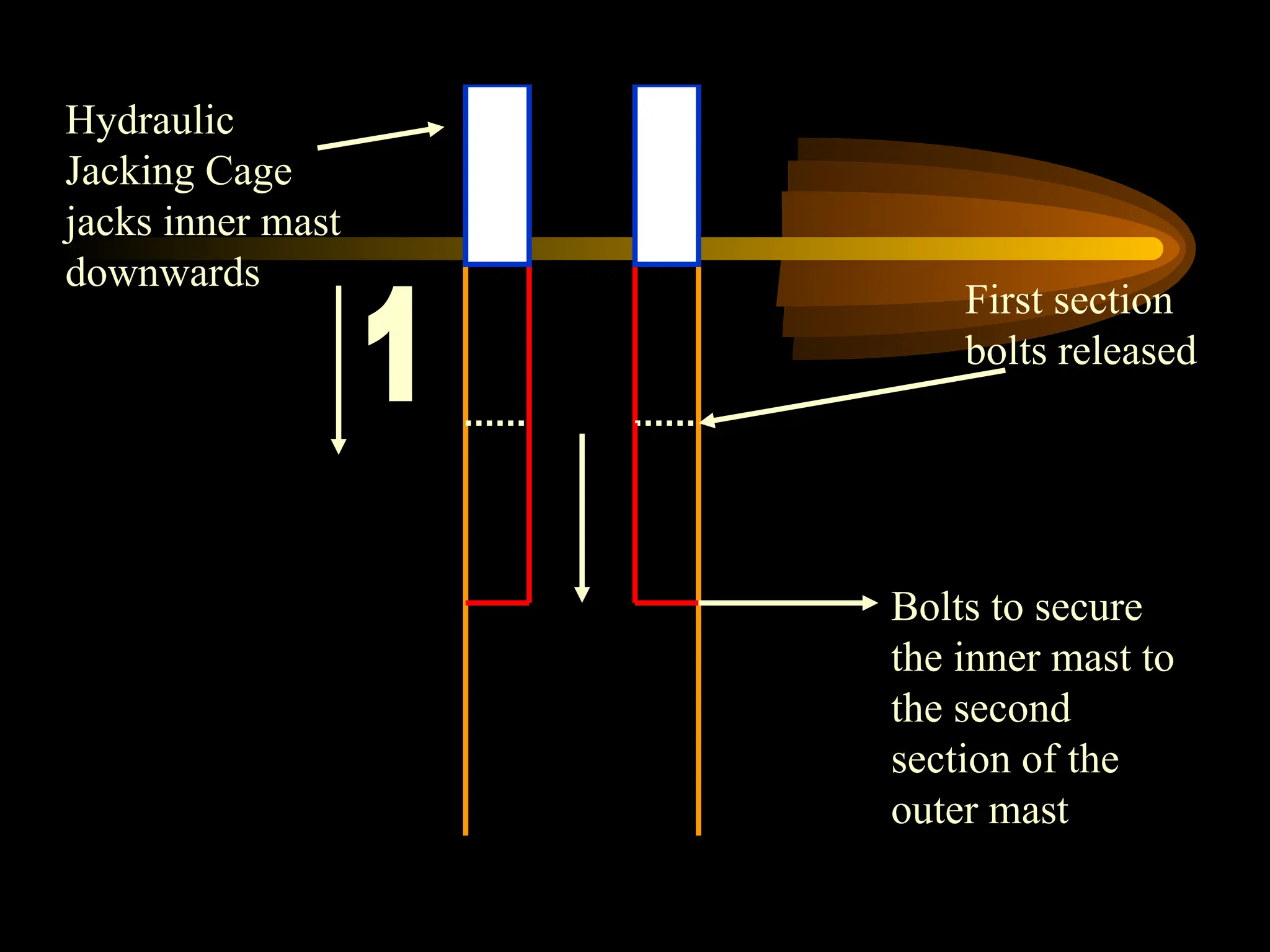

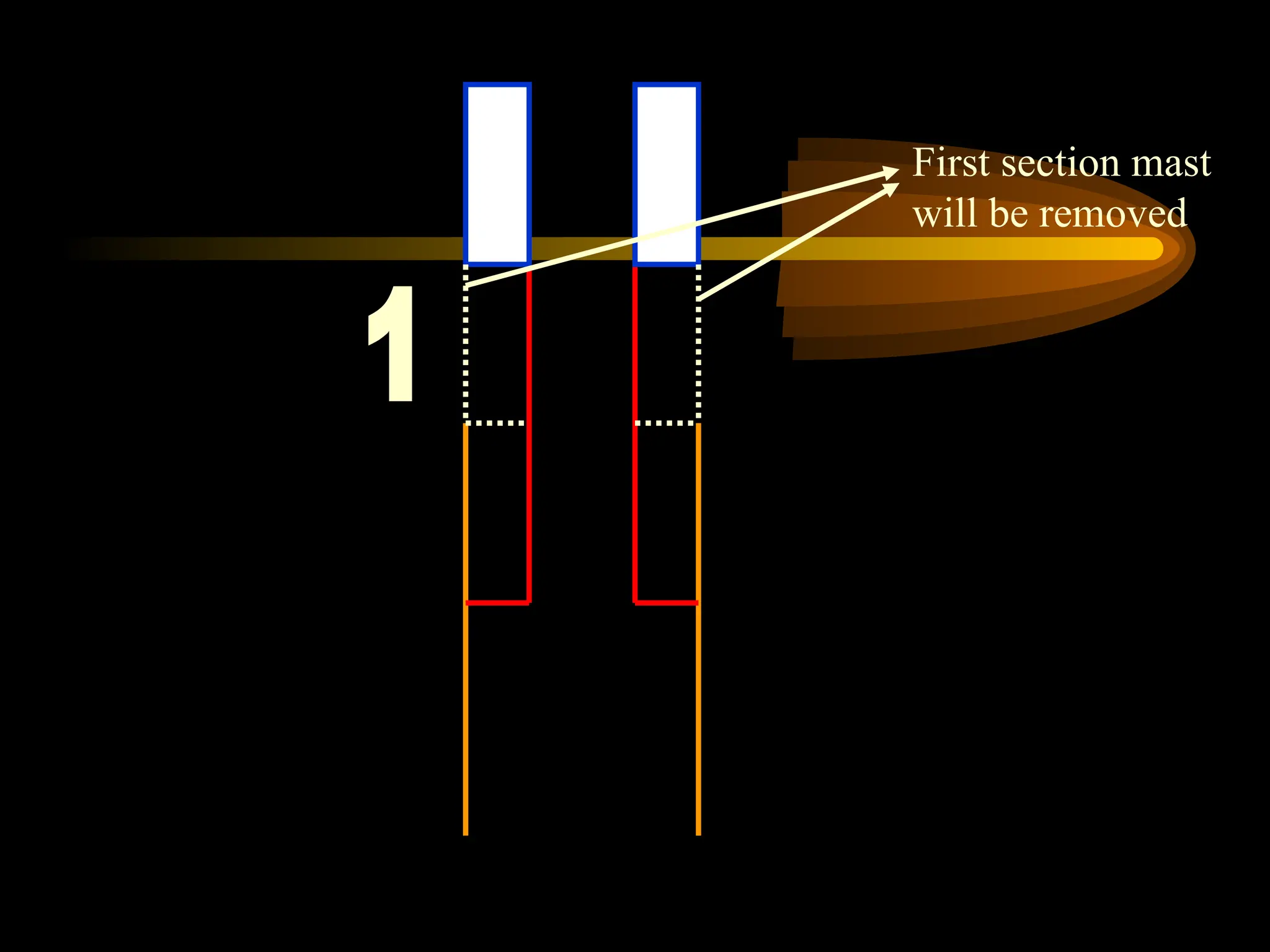

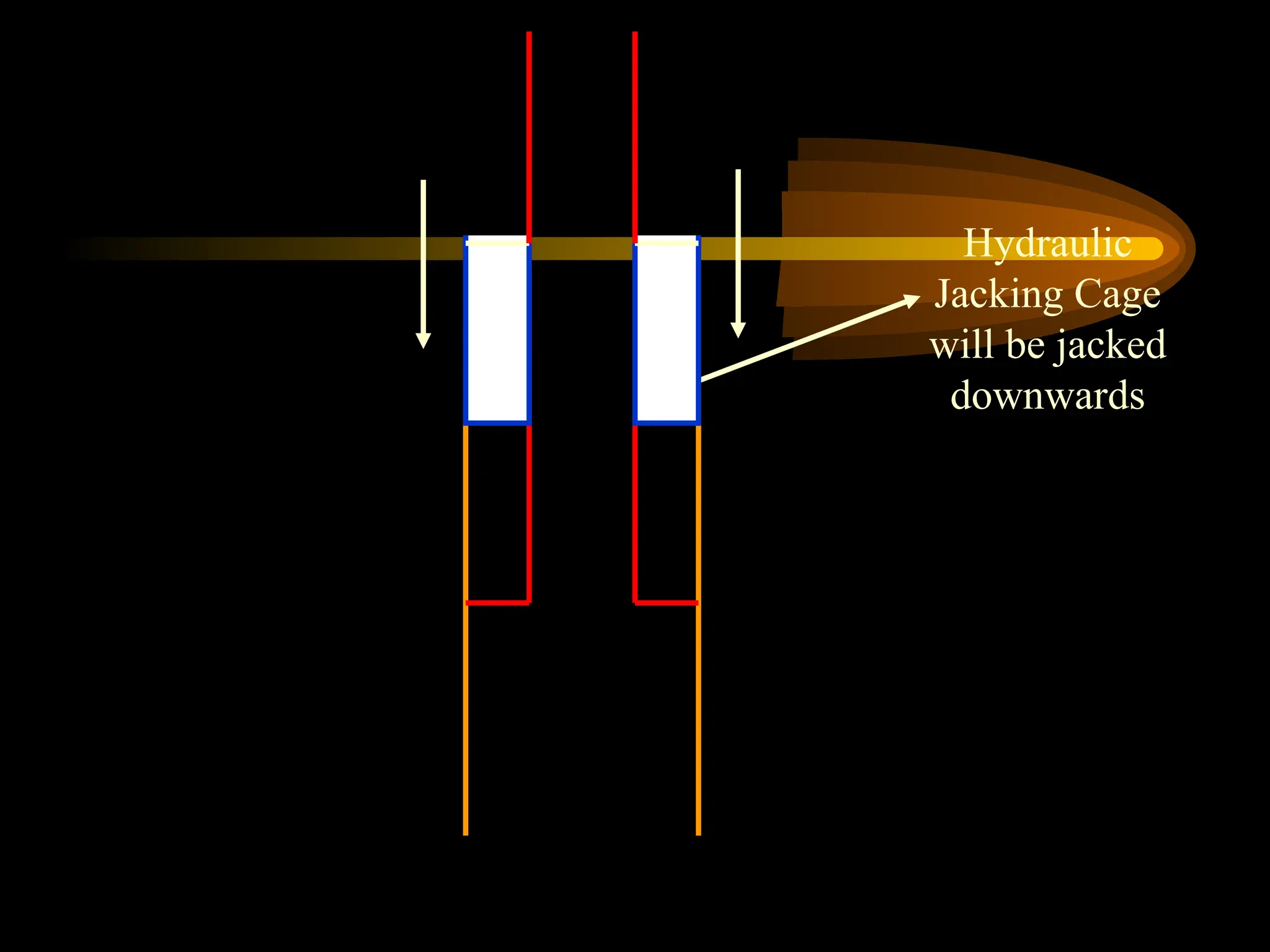

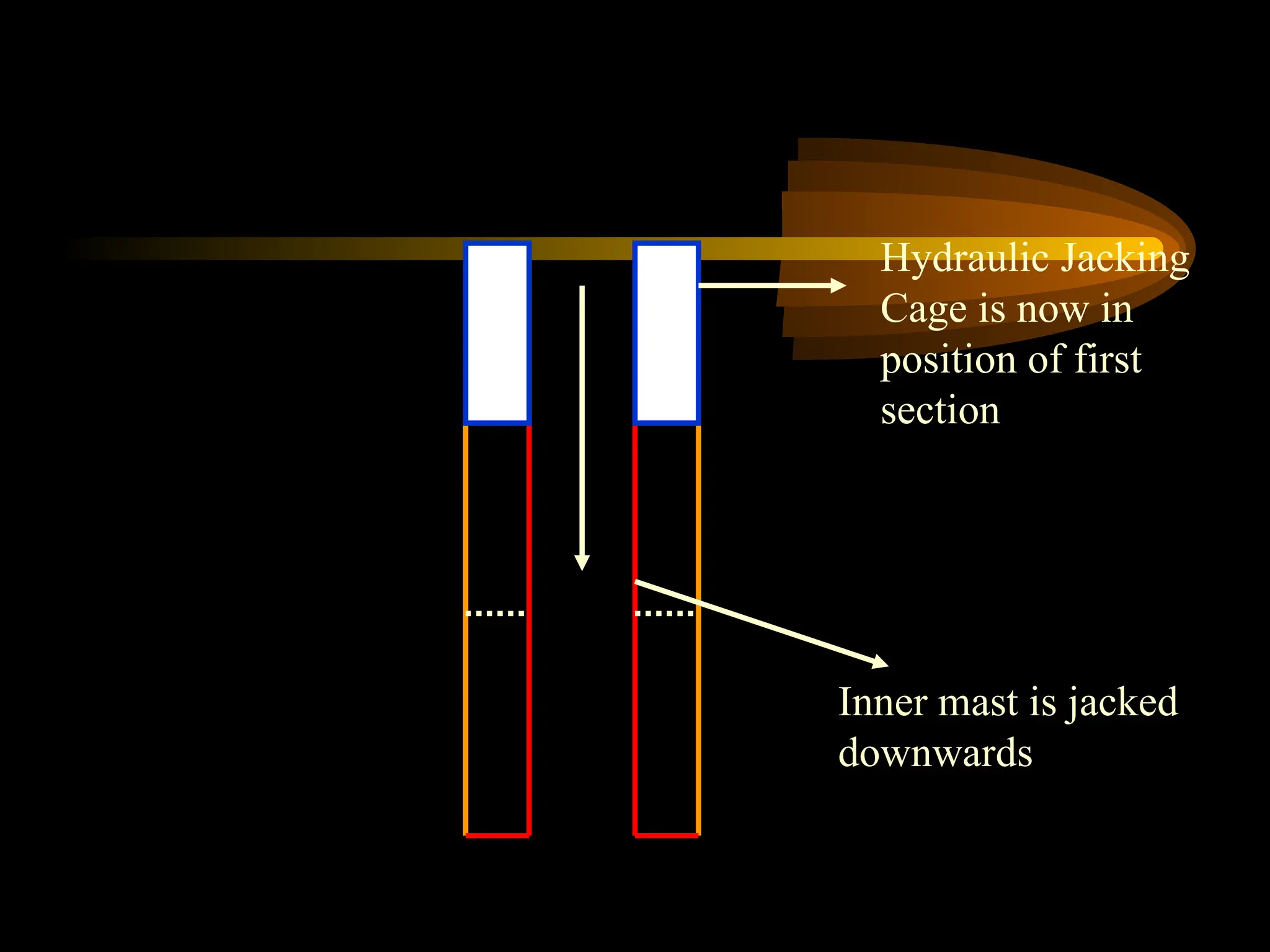

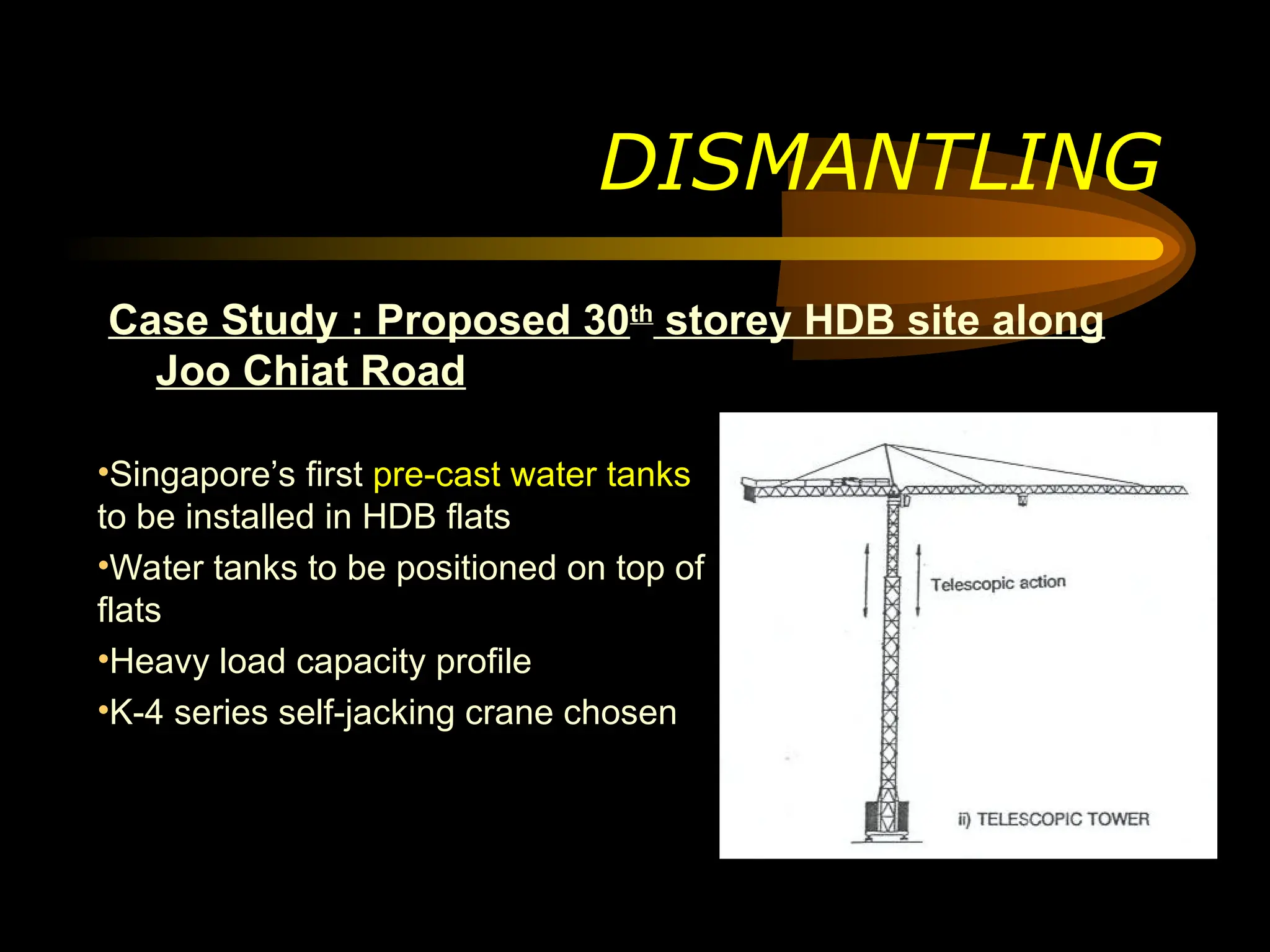

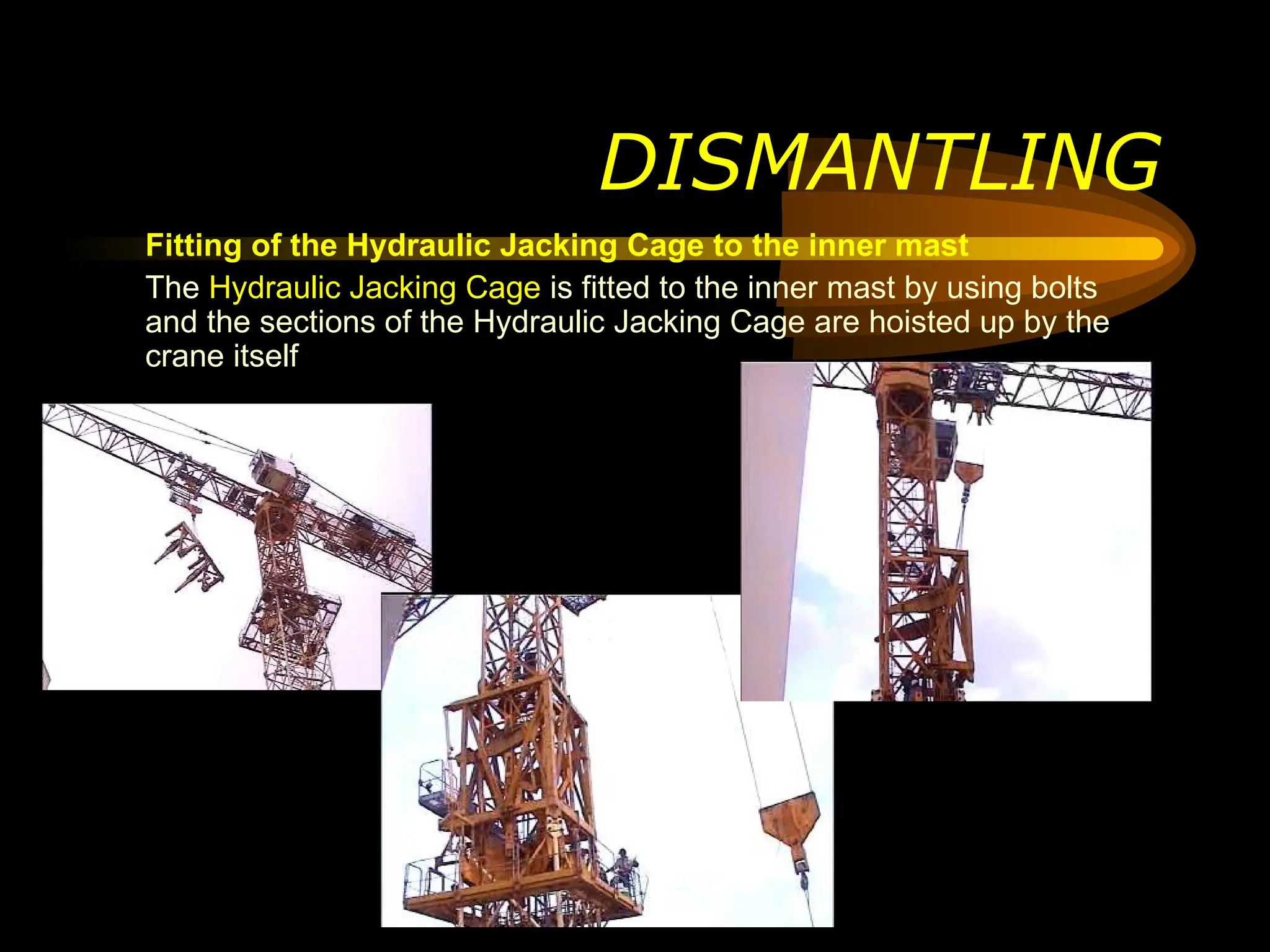

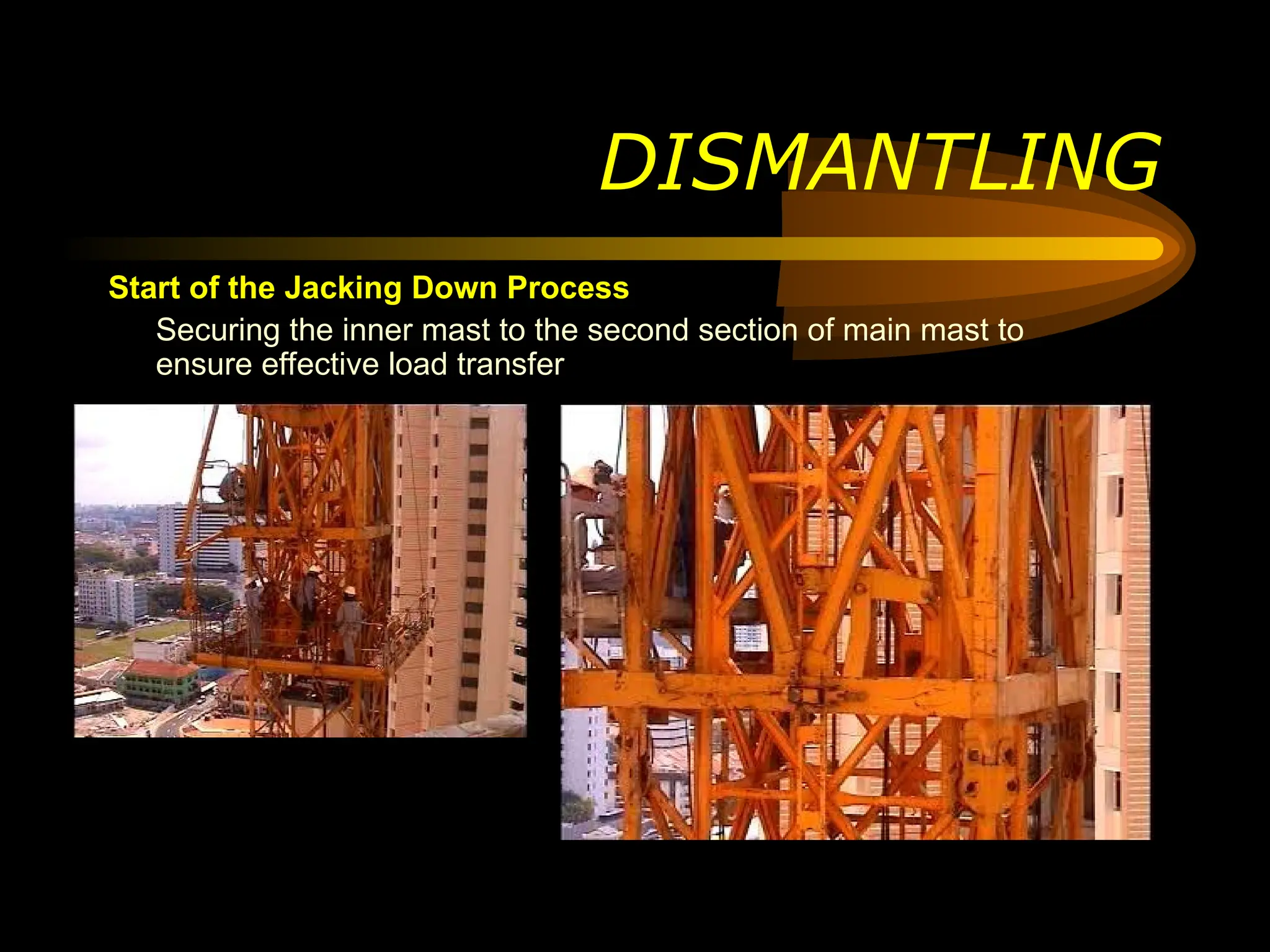

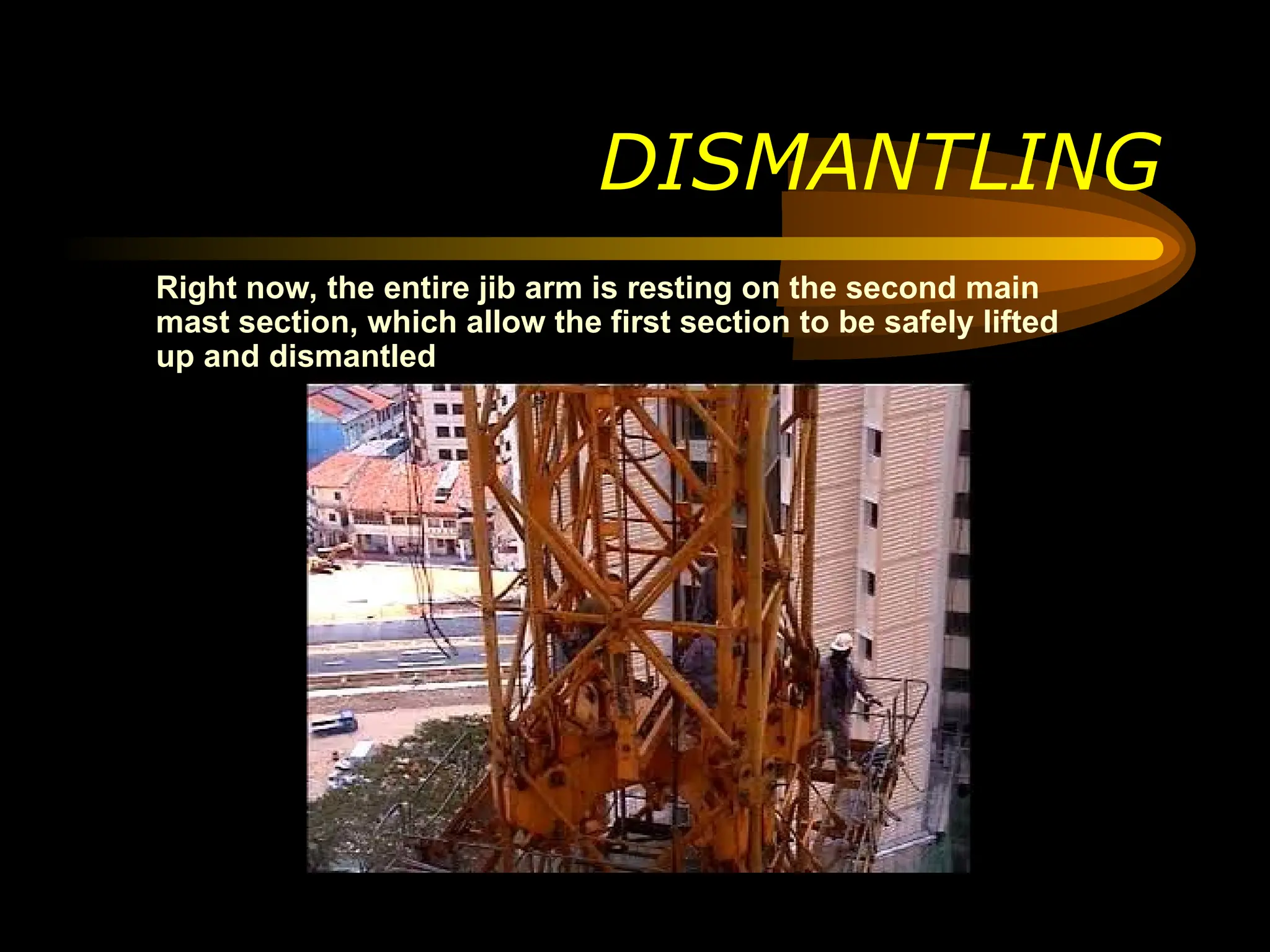

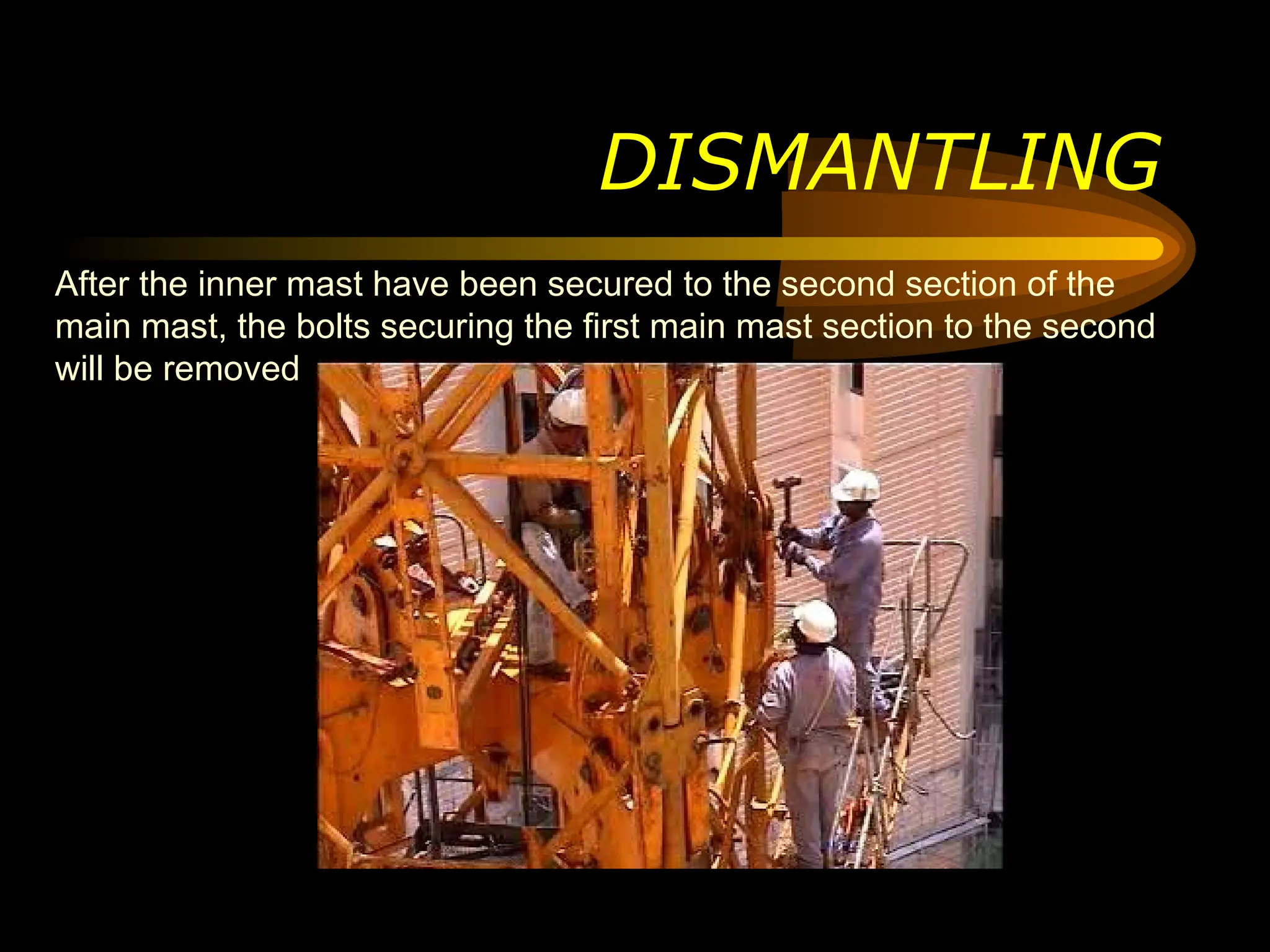

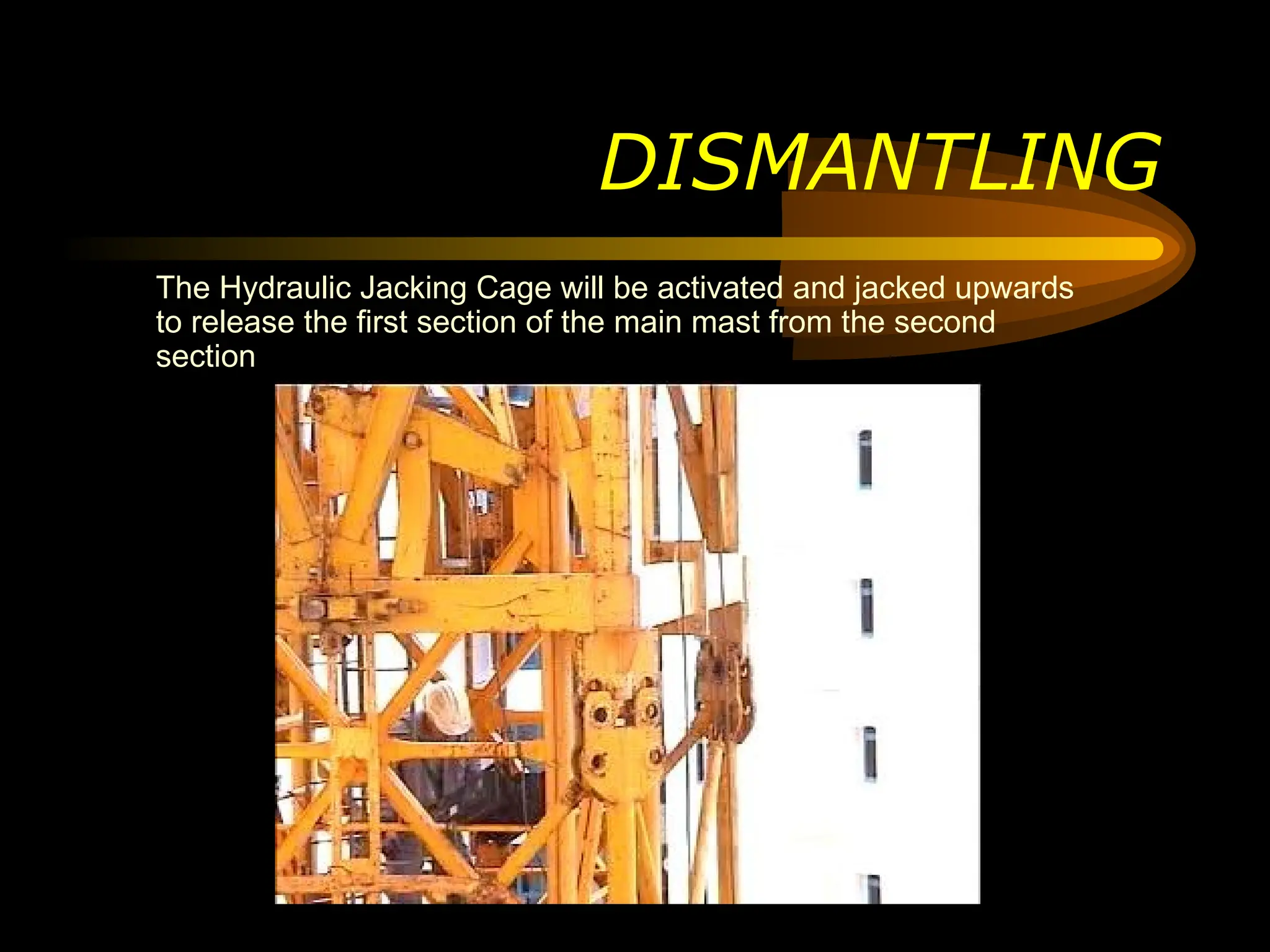

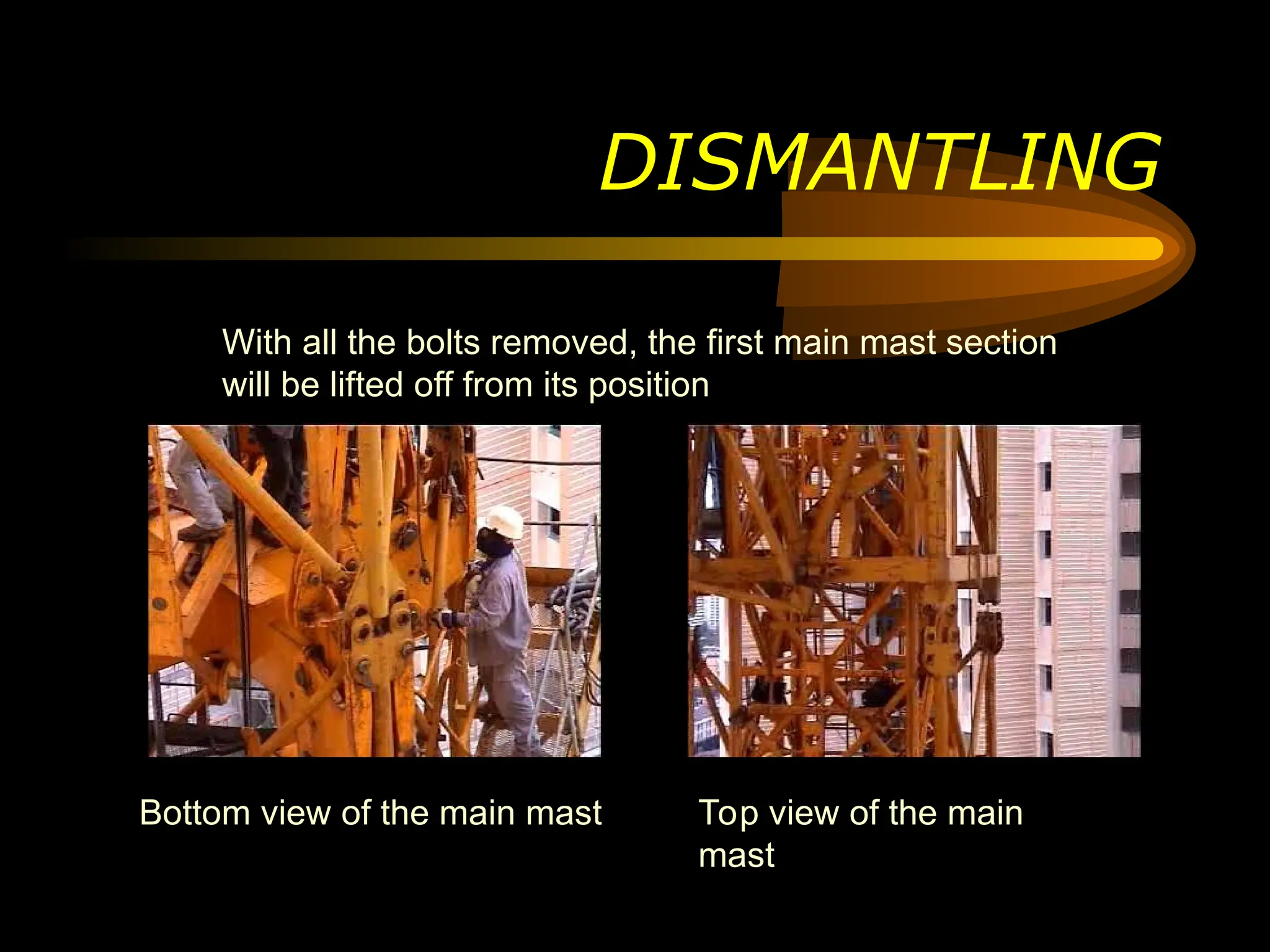

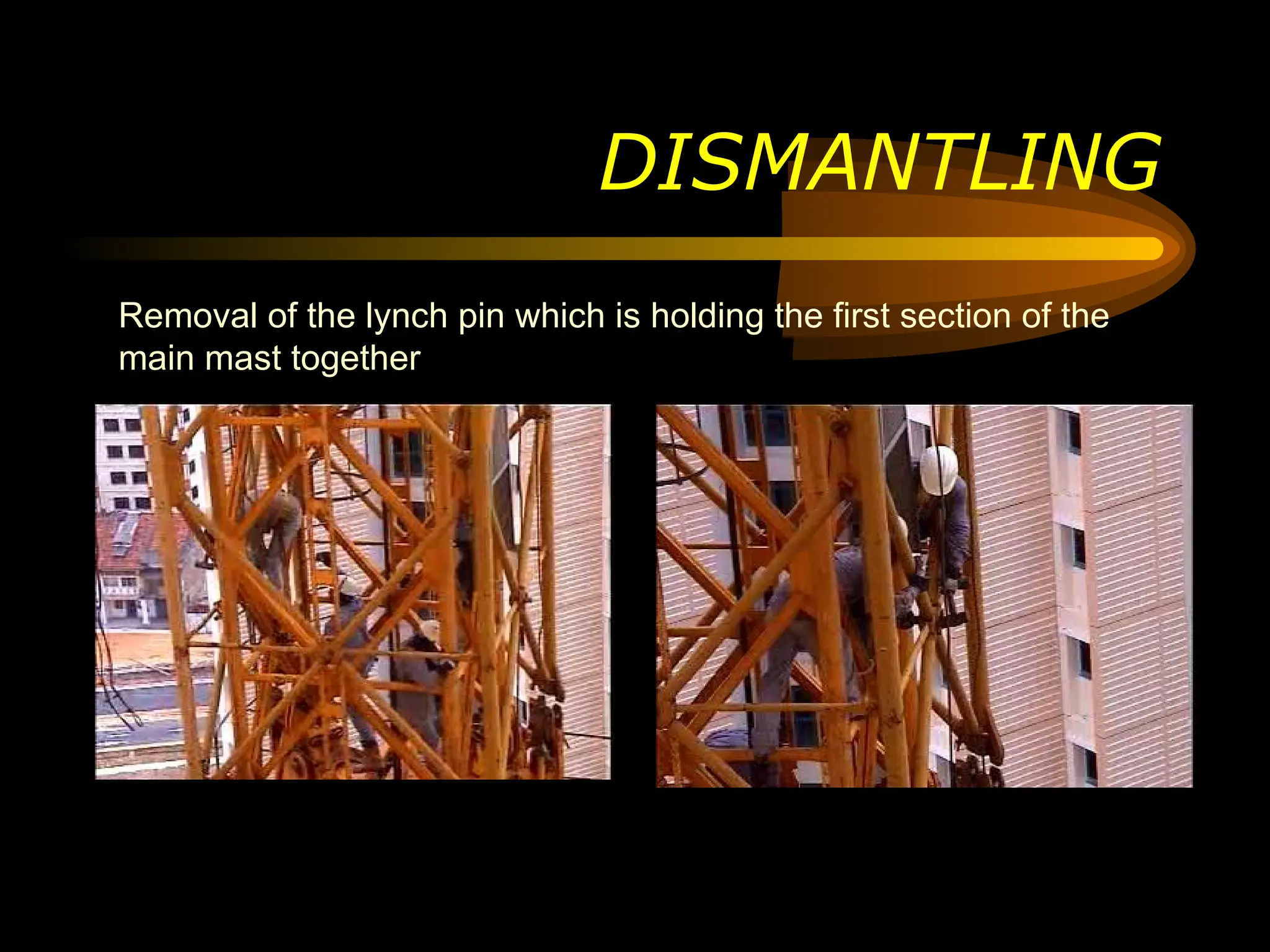

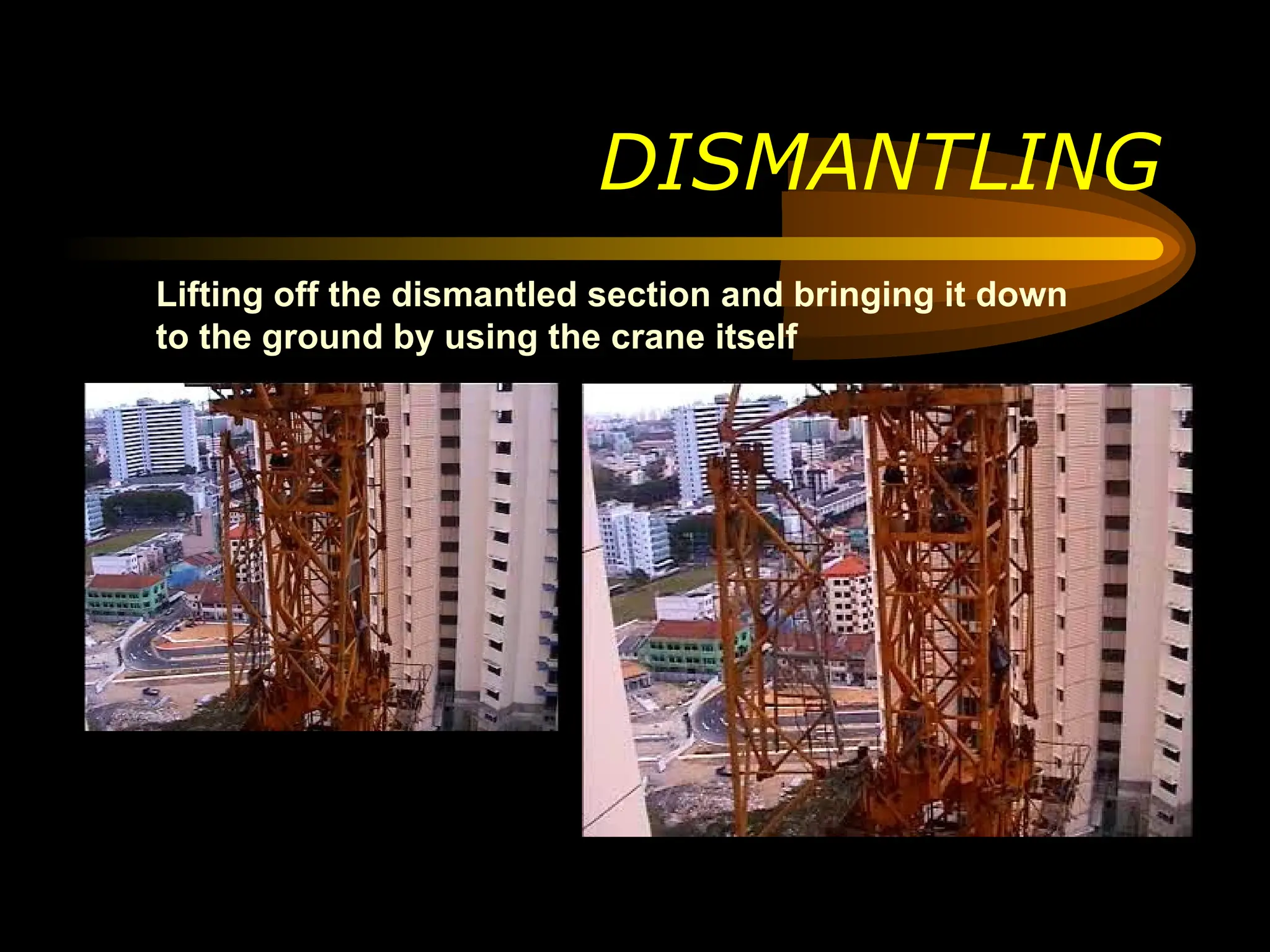

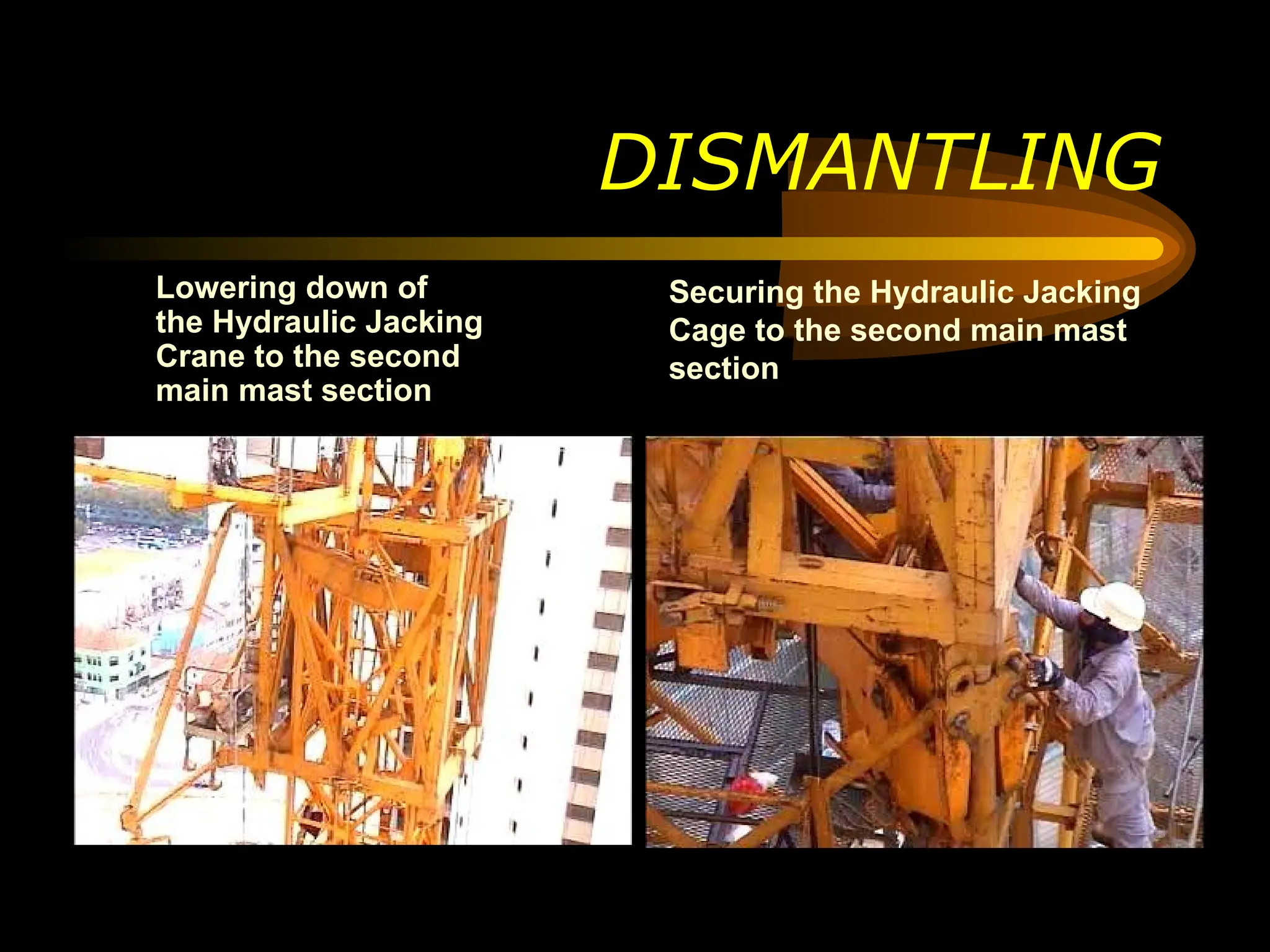

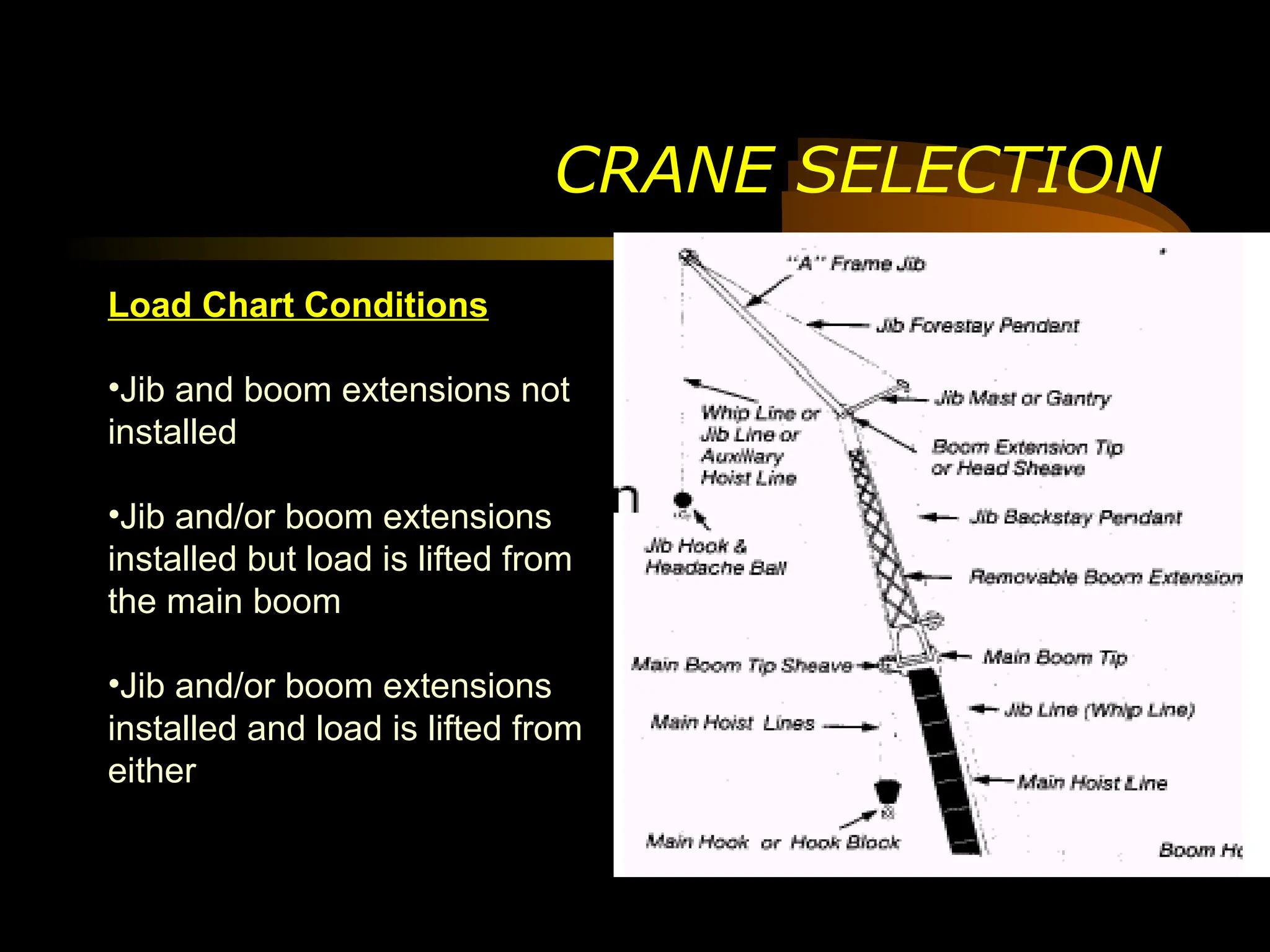

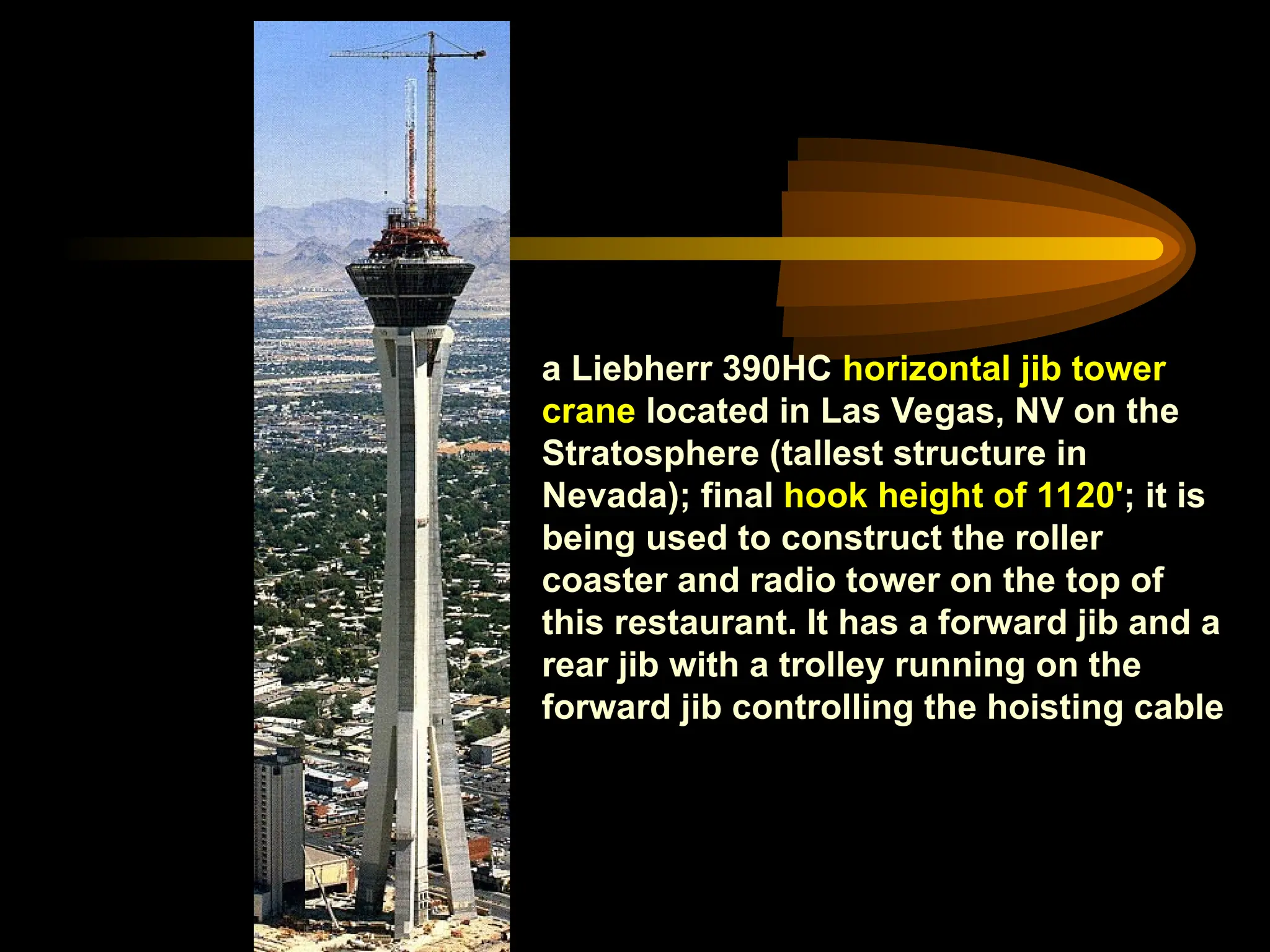

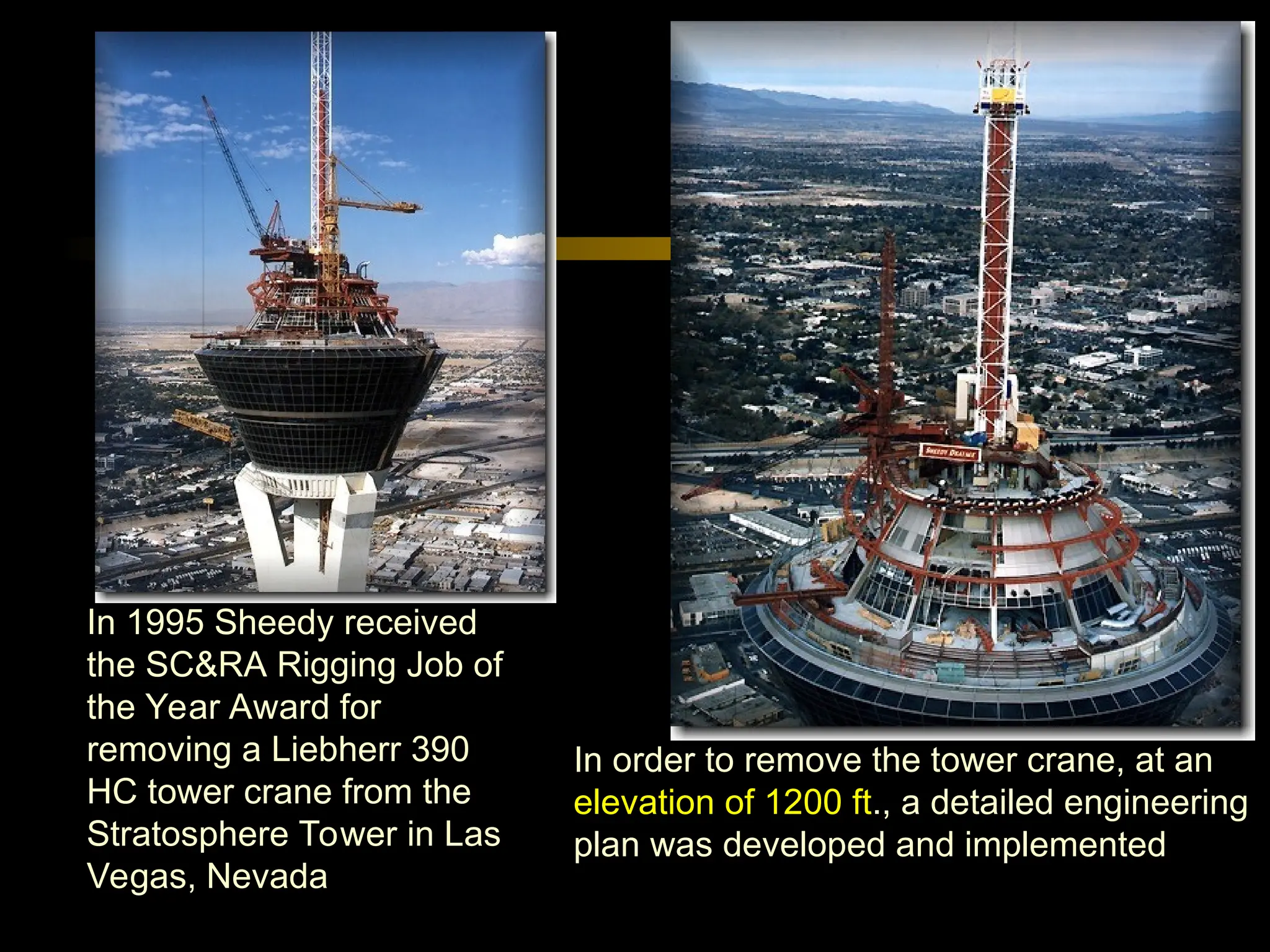

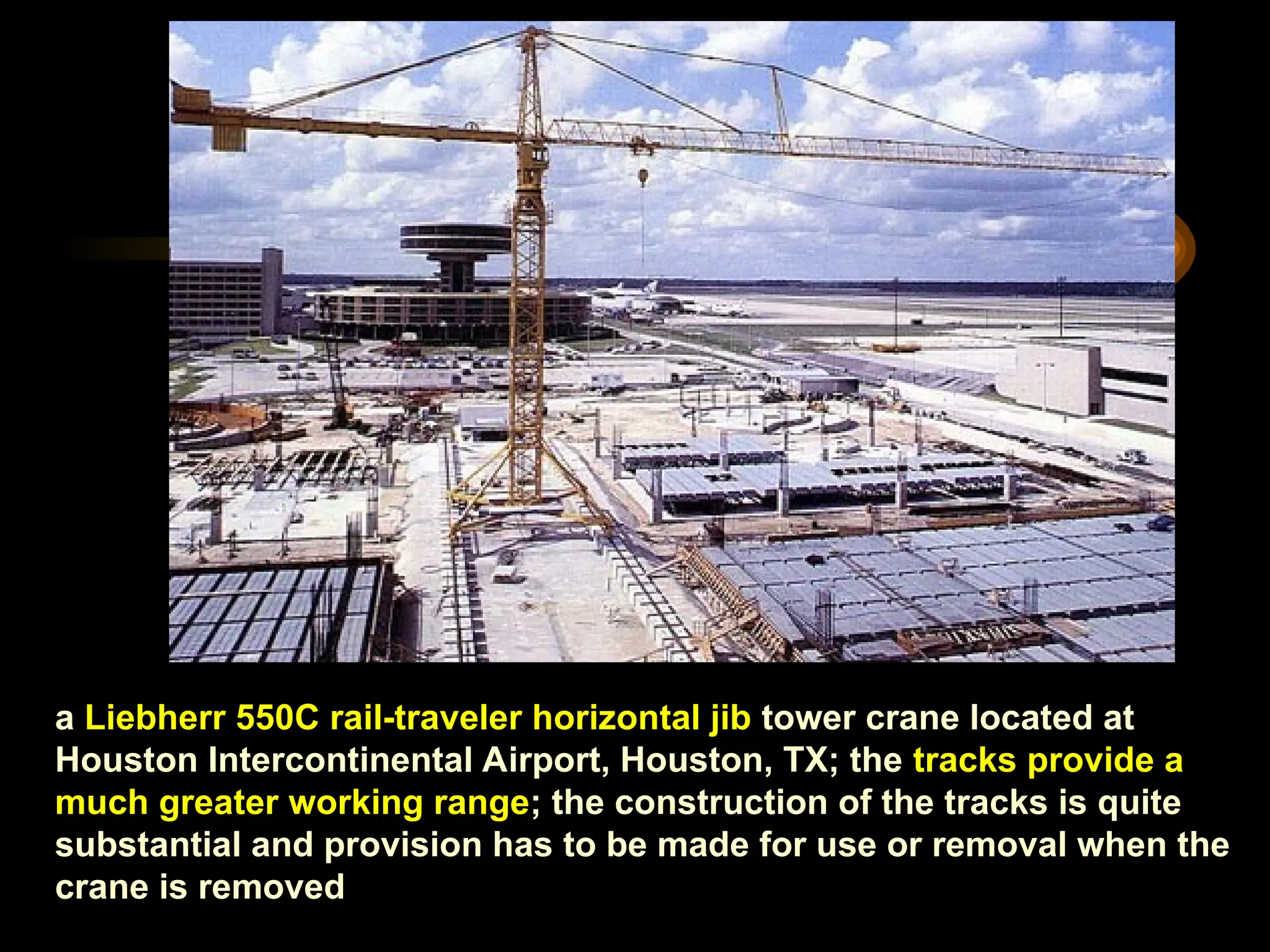

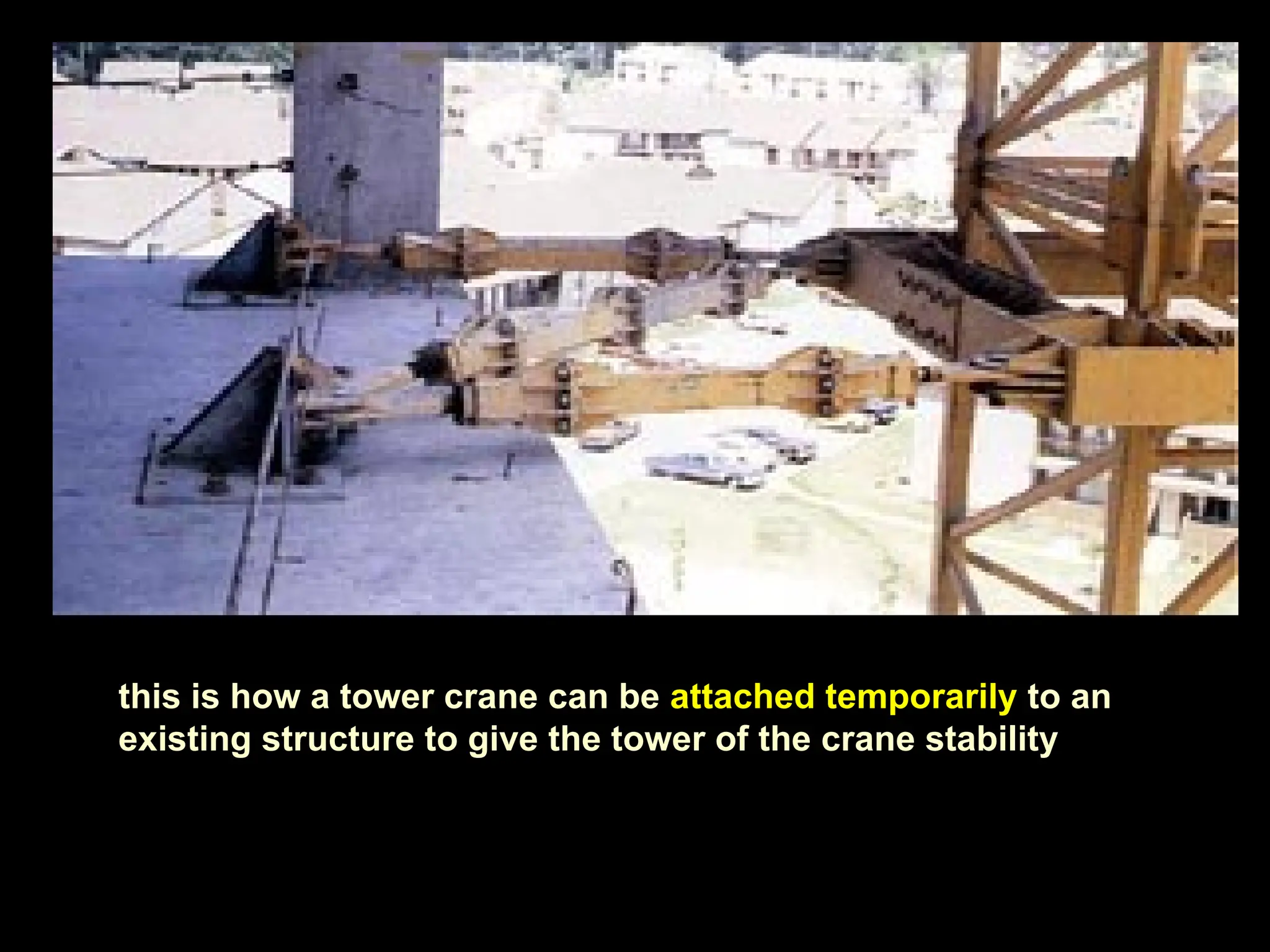

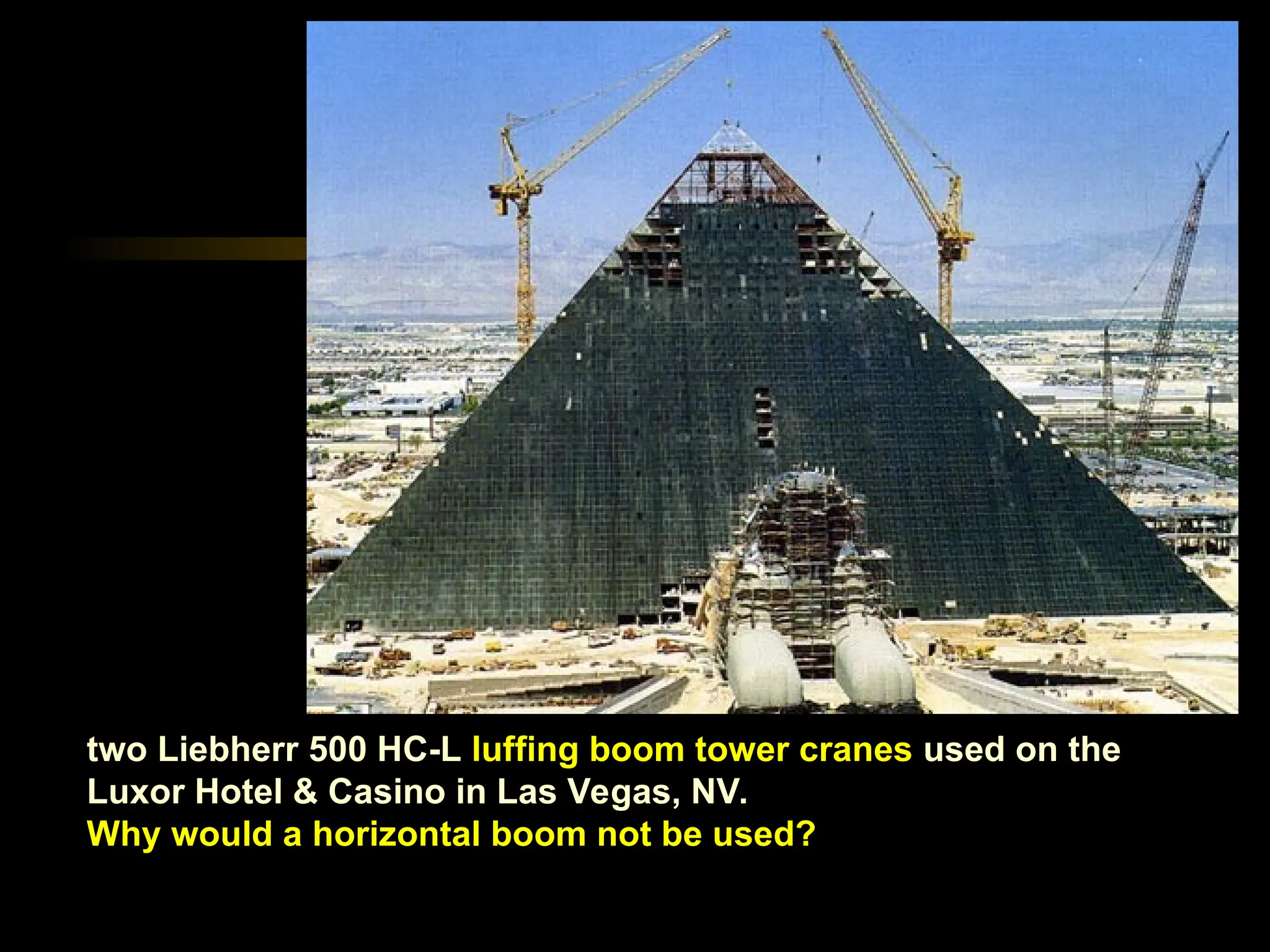

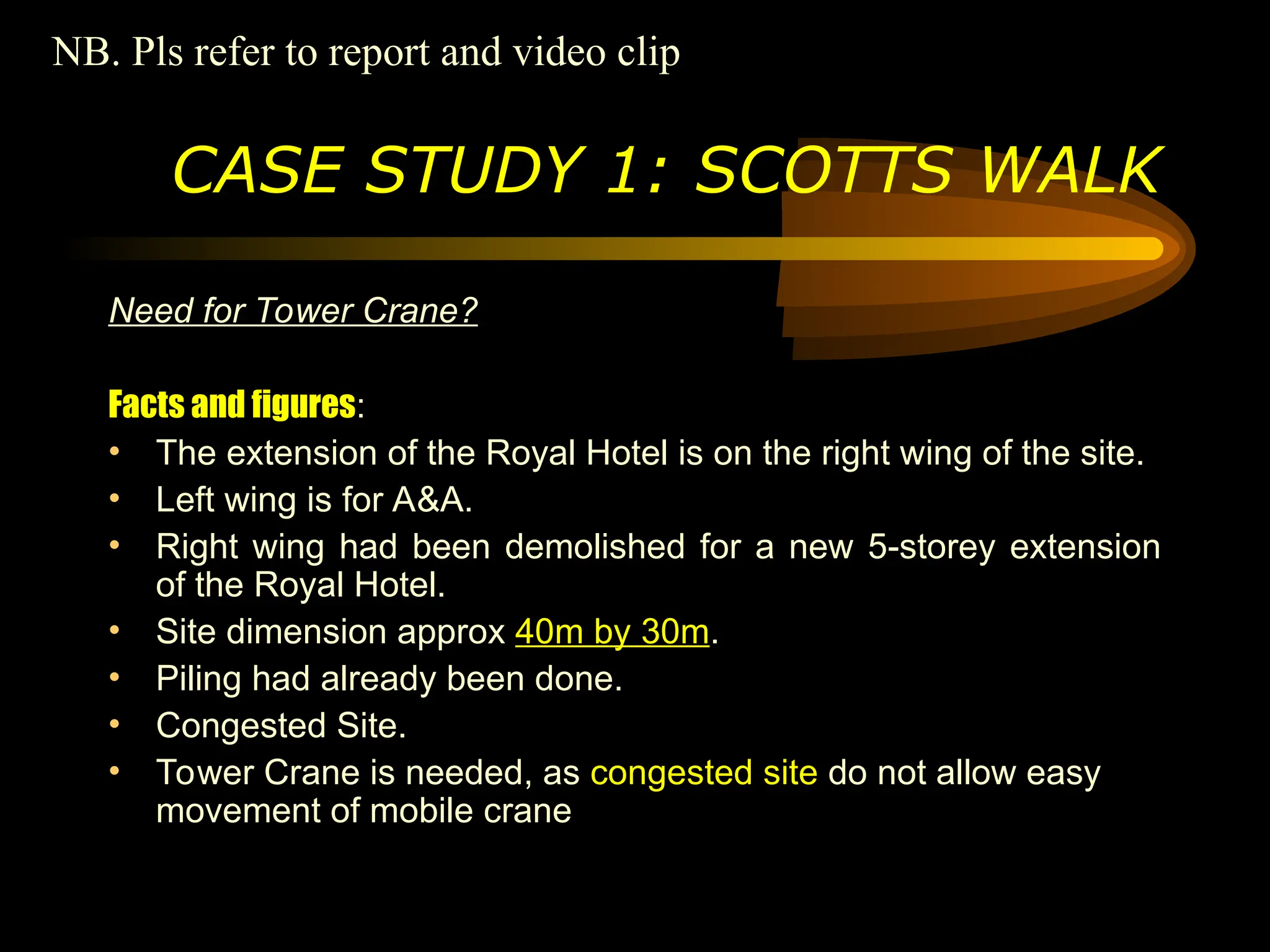

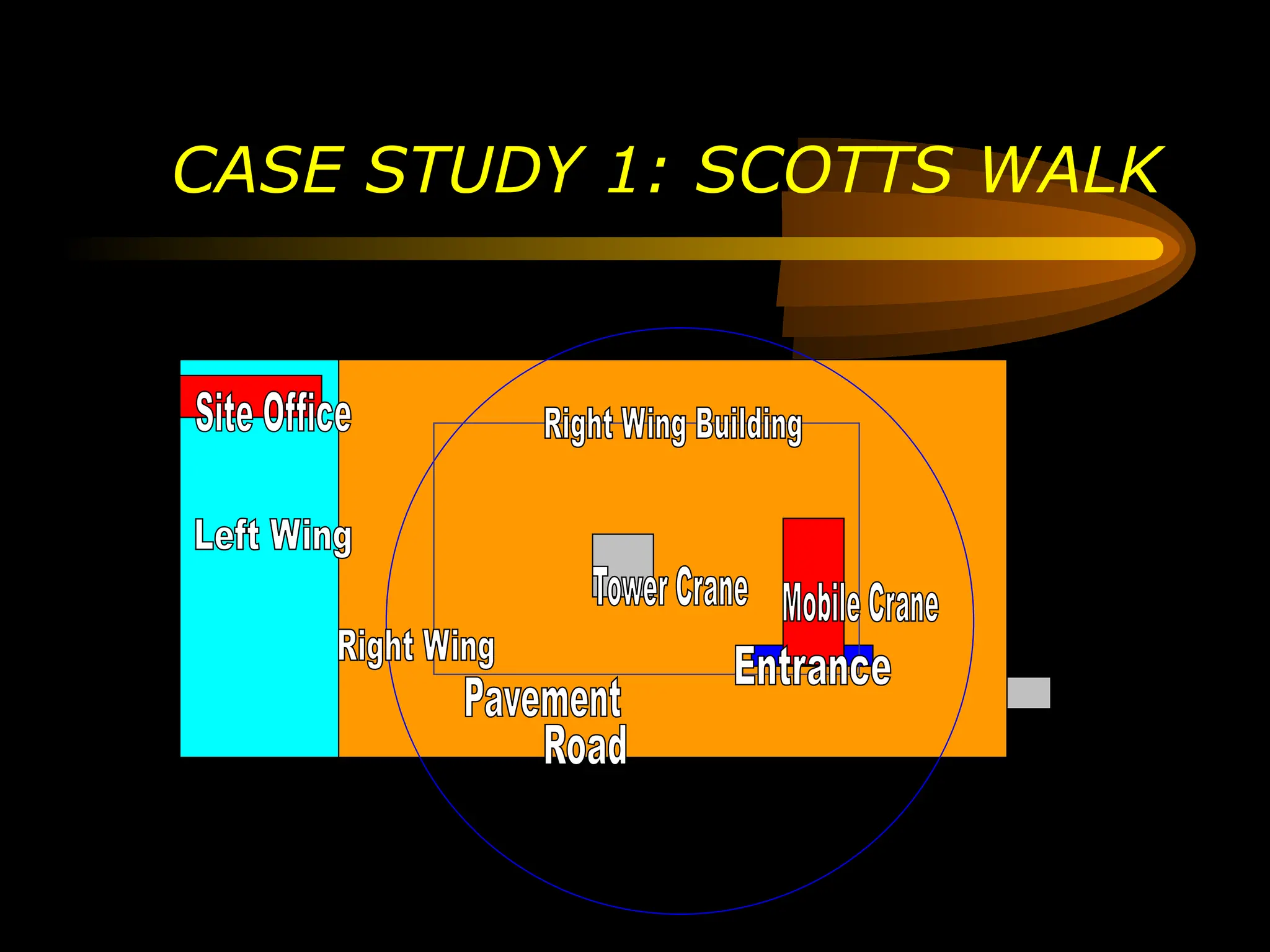

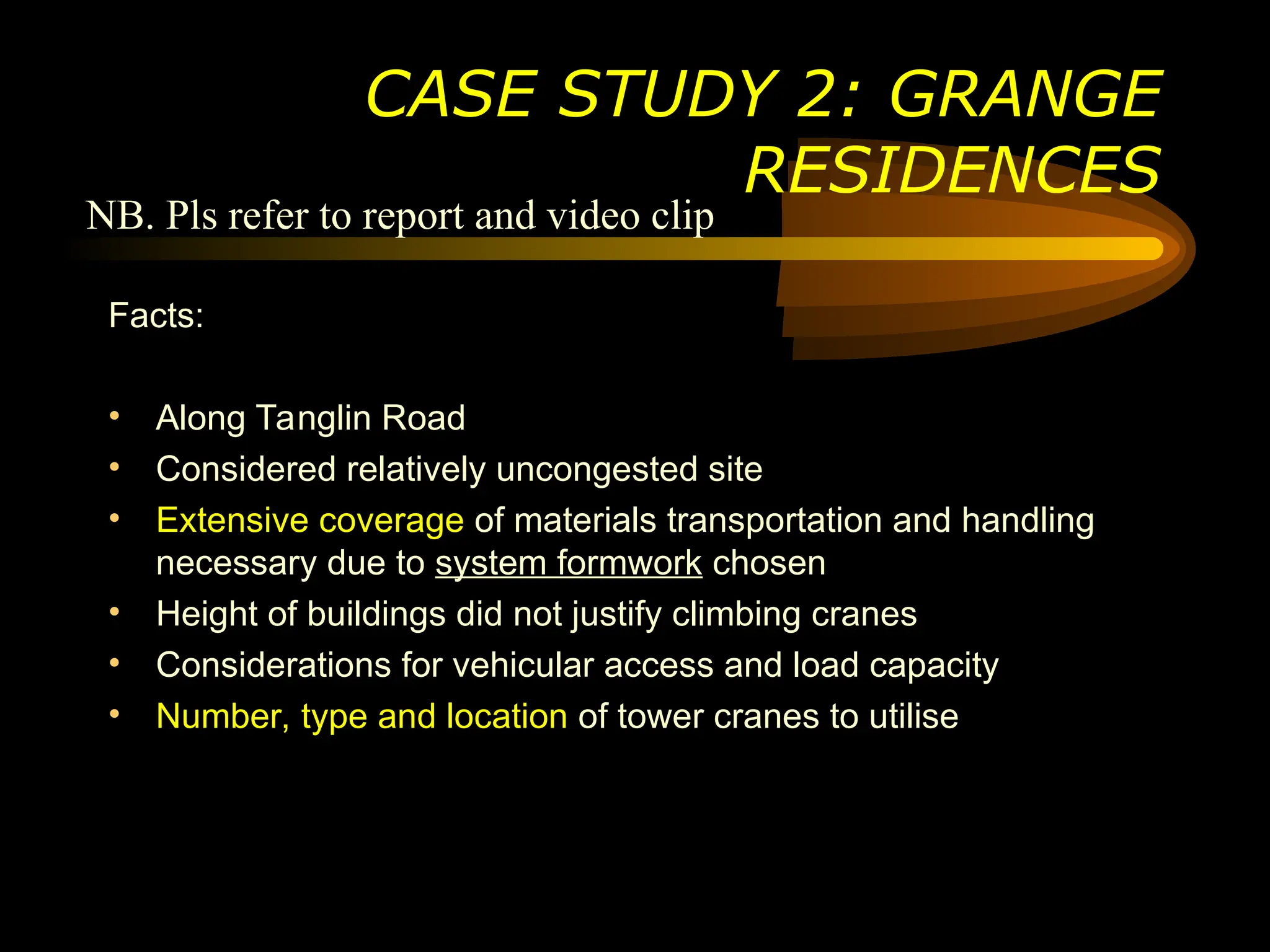

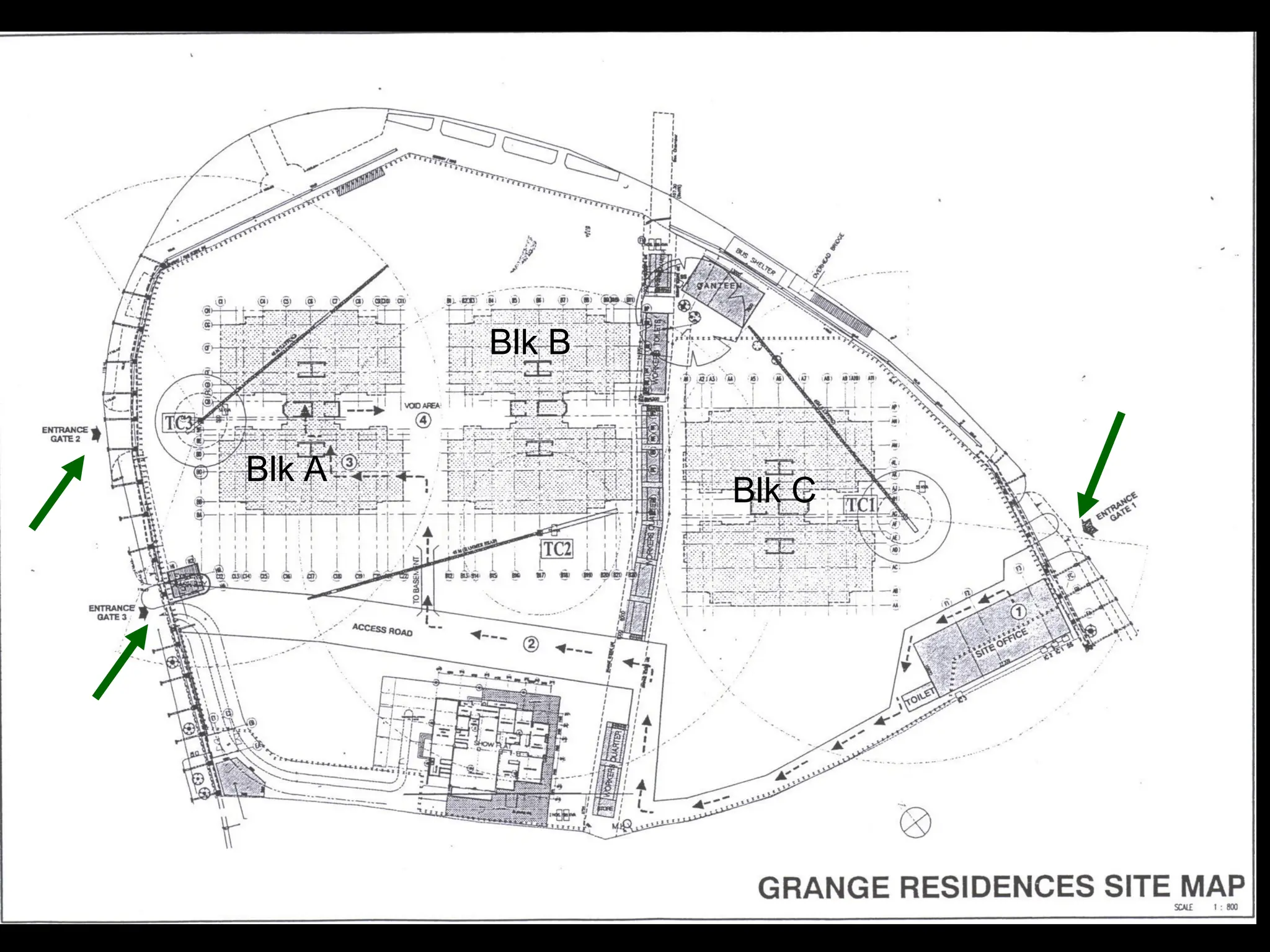

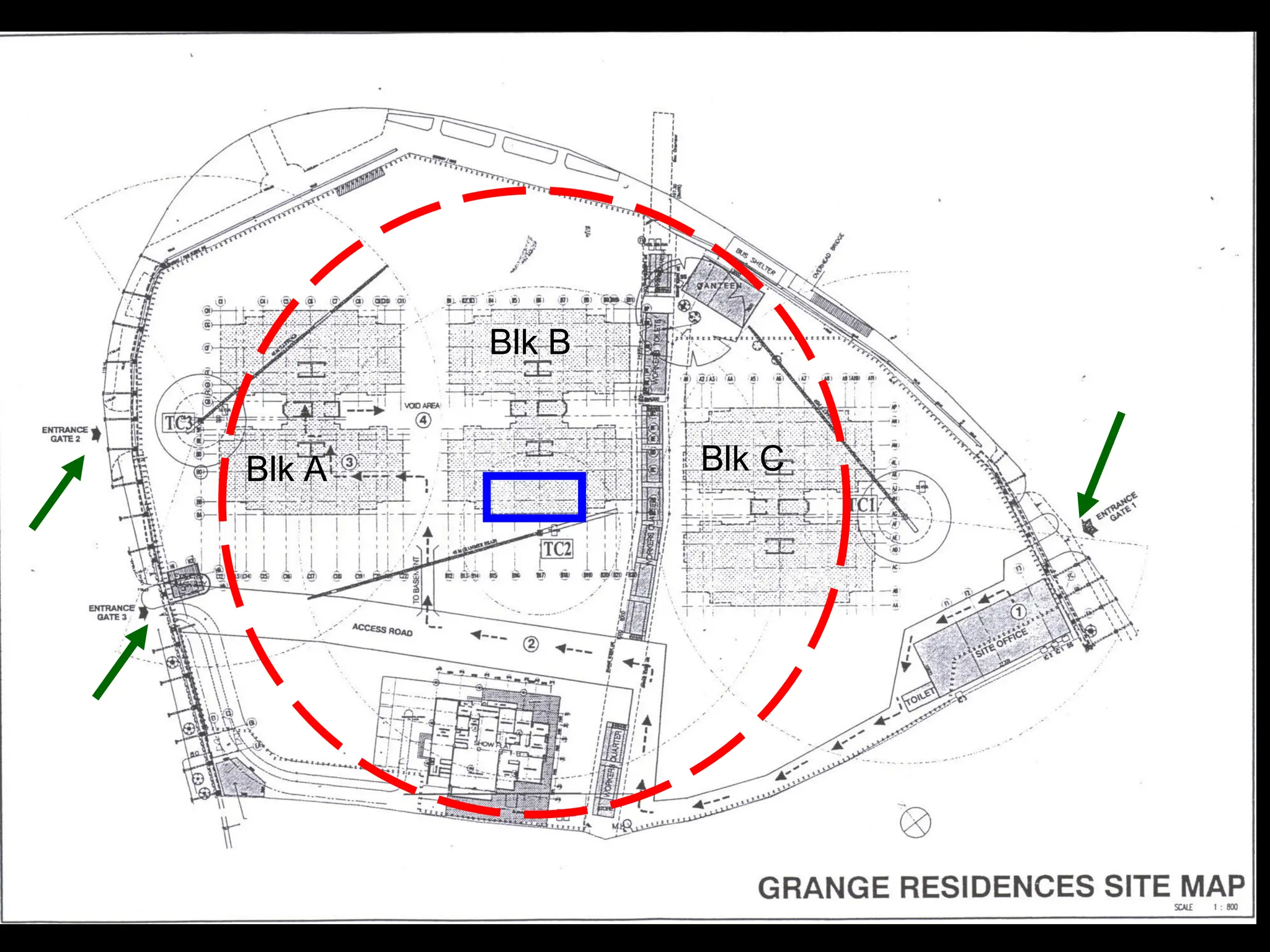

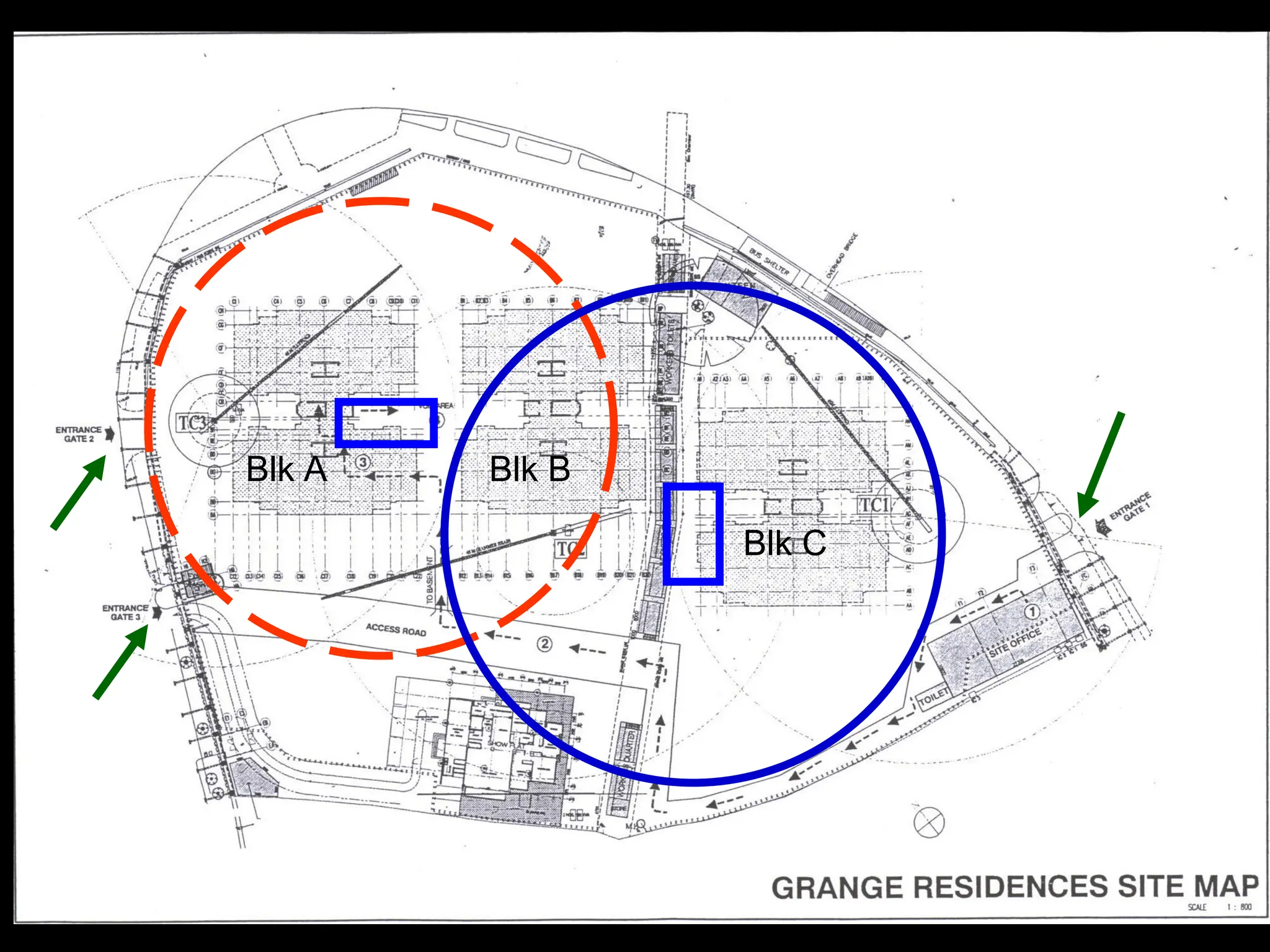

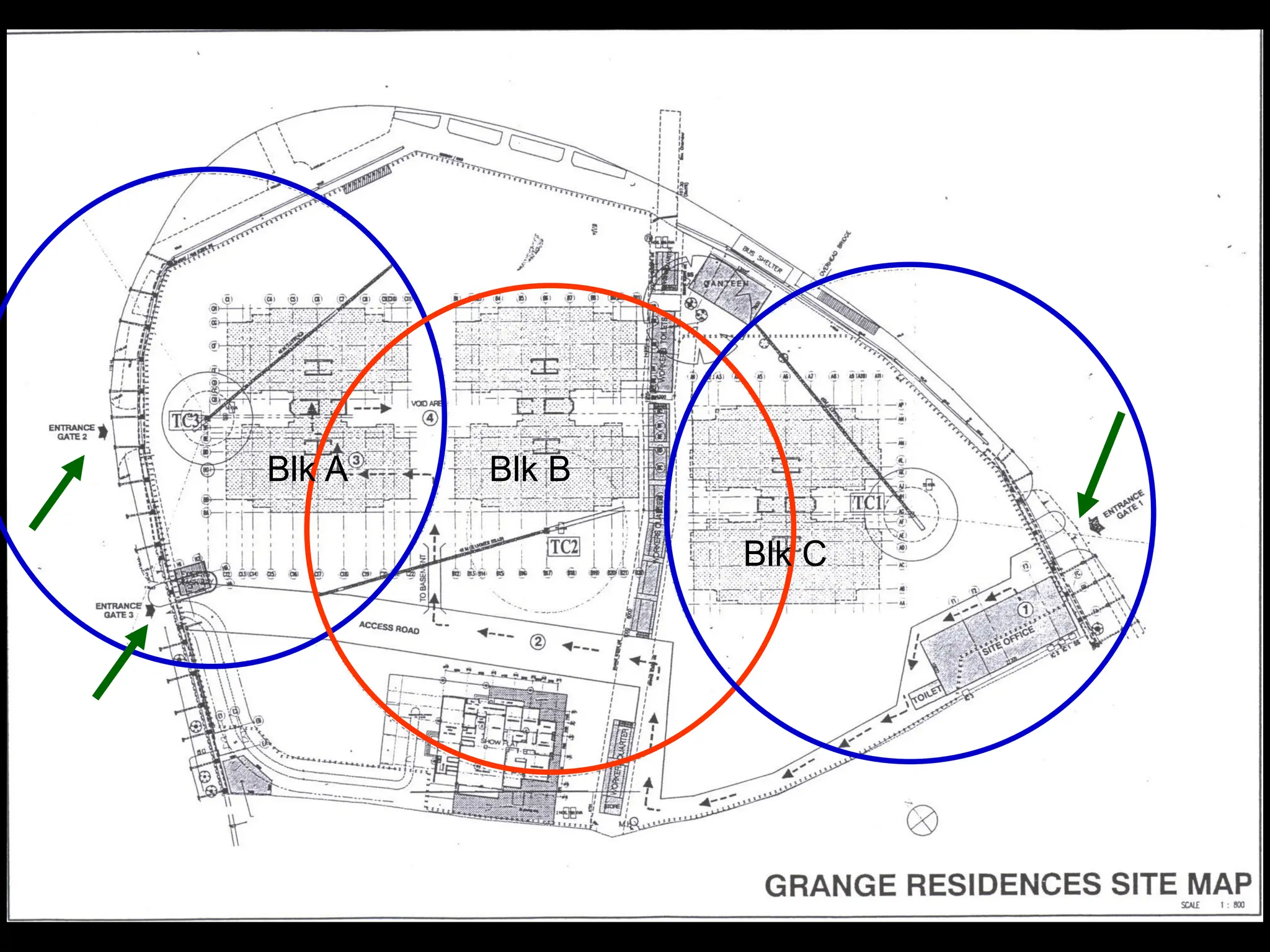

The document discusses various types of construction cranes, emphasizing tower cranes due to their extensive coverage and material transportation abilities, despite their lower capacity compared to mobile cranes. It outlines key components of tower cranes, operational conditions, maintenance requirements, and selection determinants based on factors such as location and lifting capacity. Additionally, it provides procedural guidelines for the erection and dismantling of cranes, along with case studies highlighting the practical applications of different crane types in construction projects.