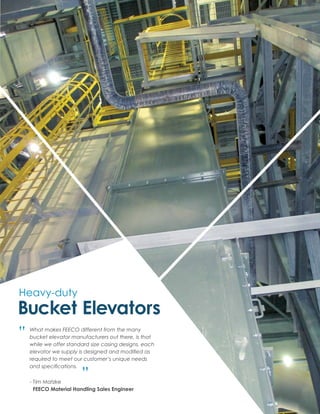

FEECO has been designing and supplying custom bulk material handling systems since 1951. They provide rugged yet refined bucket elevators and complete material handling systems tailored to customer needs. FEECO considers customer facility layouts, material characteristics, and process goals to design optimal, customized solutions. They work with companies in various industries including aggregates, animal feeds, coal, and more. FEECO bucket elevators are available in different configurations to accommodate any handling job.