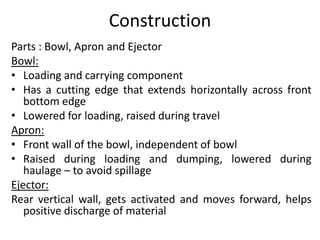

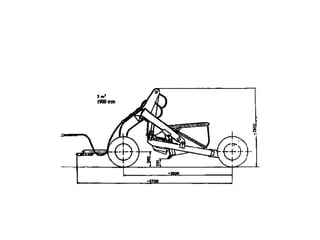

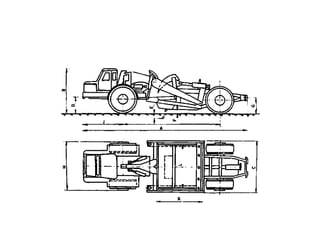

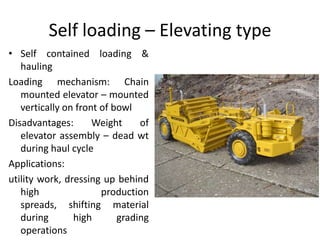

This document discusses tractor pulled scrapers, which are versatile machines used to load, haul, and dump loose materials like soil over a range of haul distances. Scrapers have three main parts - a bowl for loading and carrying material, an apron on the front of the bowl, and an ejector in the rear. They follow a production cycle of loading, hauling, dumping, turning, and returning to load again. Scrapers are classified based on their loading method as pusher loaded, self-loading push-pull, elevating, or auger types. Pusher loaded scrapers rely on other equipment to load them while self-loading types can load independently. Scrapers are rated based on their struck