1) Marcep Inc. is hosting a two-day training workshop on smart instrumentation for process plants in Chennai from February 5-6 and Ahmedabad from February 8-9.

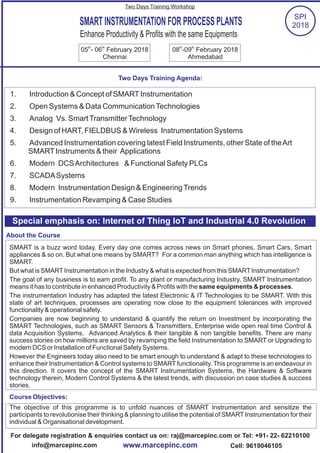

2) The training will cover topics such as smart sensor and transmitter technologies, modern control systems trends, case studies on improving productivity and profits through smart instrumentation.

3) Attendees will learn how to integrate smart technologies into their existing plants and understand the benefits of systems like distributed control systems (DCS) and functional safety systems.