1) The document discusses the ICT requirements for smart factories, which use cyber-physical systems and the internet of things to increase flexibility and efficiency in production.

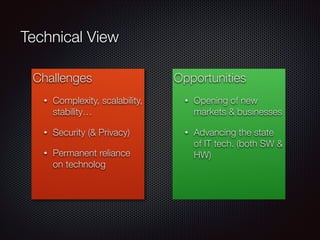

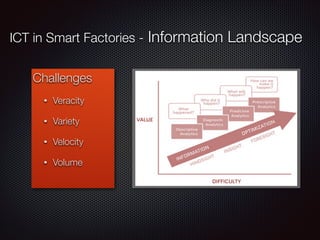

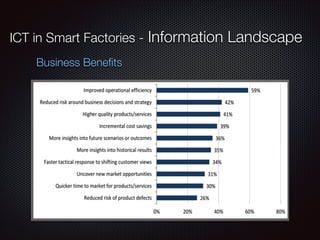

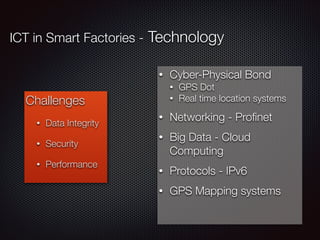

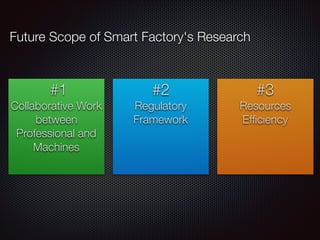

2) It outlines the opportunities of smart factories like shorter product development and increased competitiveness, but also challenges like ensuring security, scalability, and dealing with large amounts of diverse real-time data.

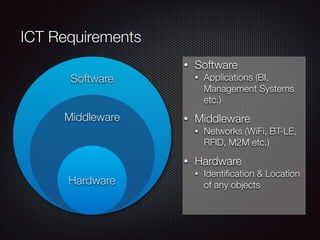

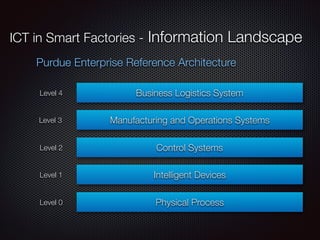

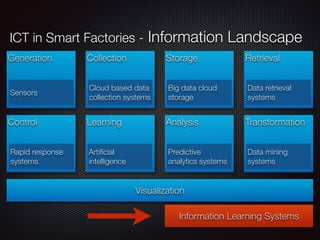

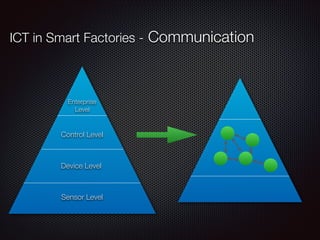

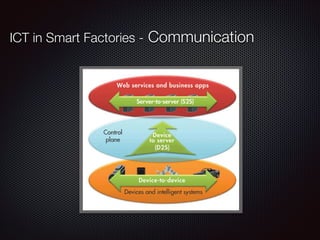

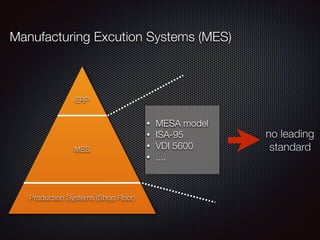

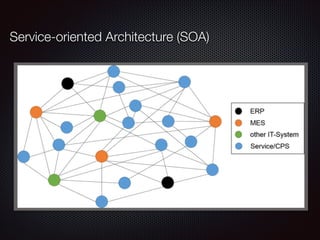

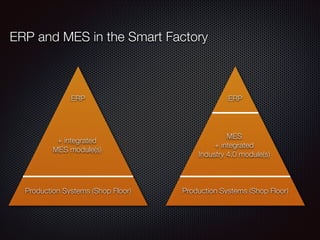

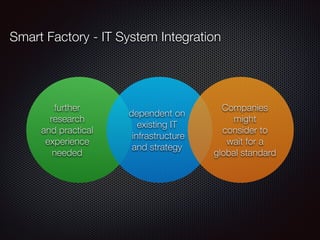

3) The document examines the different levels of an ICT infrastructure for smart factories including software, middleware, hardware, sensors, networks, and systems for data collection, storage, analysis and control that link enterprise, control and device levels.