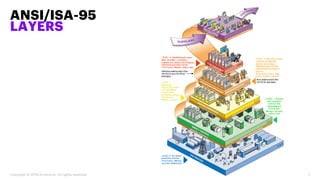

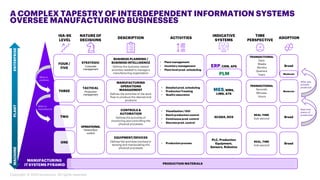

The document discusses Accenture's expertise in industrial digital transformation, focusing on smart manufacturing and the integration of enterprise and process control systems using ANSI/ISA-95 standards. It emphasizes the benefits of smart manufacturing from a management perspective, highlighting real-world implementations and the importance of use cases and user requirement specifications in project definition. The presentation concludes with a call for proactive innovation and problem-solving in manufacturing environments.