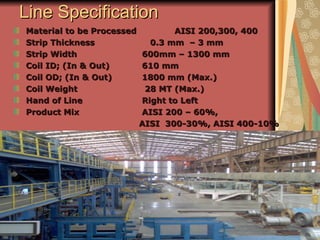

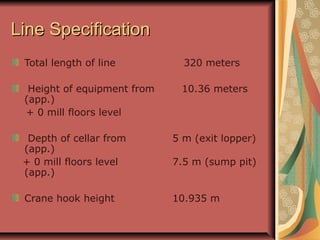

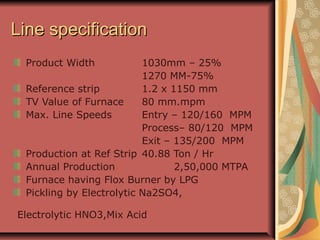

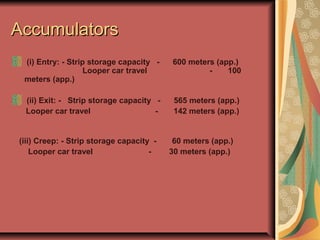

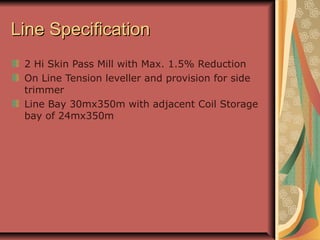

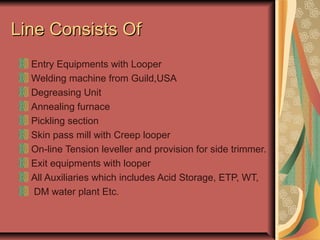

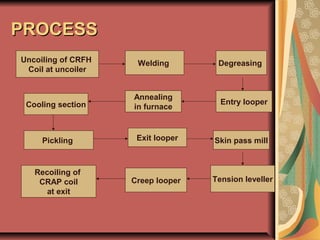

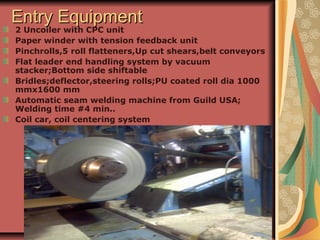

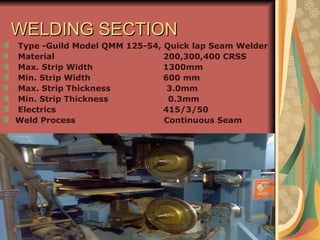

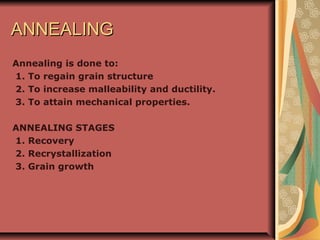

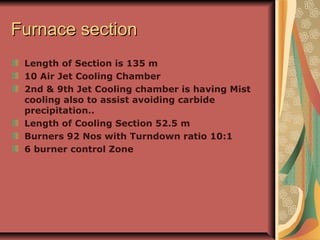

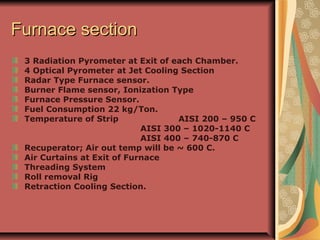

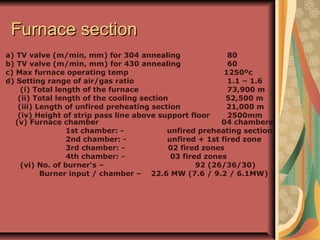

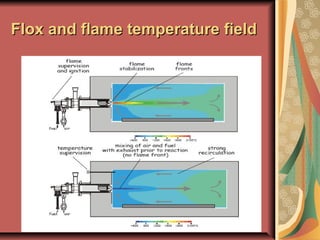

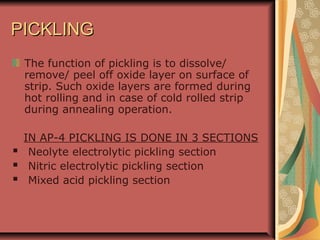

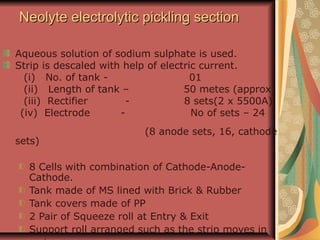

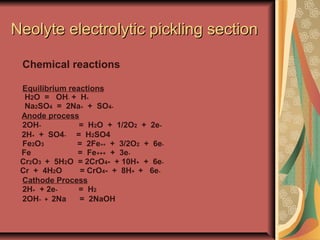

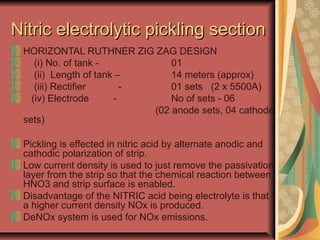

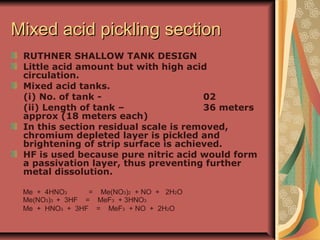

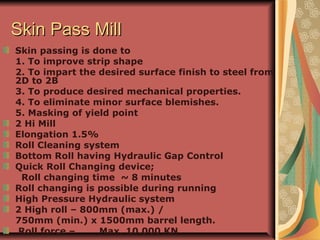

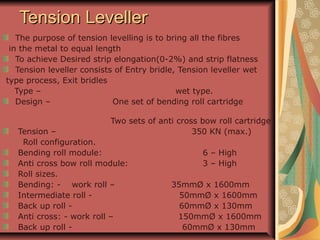

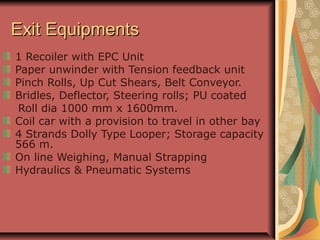

The document describes the specifications and processes involved in annealing and pickling a stainless steel coil. The line can process AISI 200, 300, and 400 grade stainless steel coils that are 0.3-3 mm thick and 600-1300 mm wide. The processes include welding, degreasing, annealing in a furnace, pickling using electrolytic sulfuric acid and mixed acid tanks, skin passing using a two-high mill, tension leveling, and recoiling. The goal is to improve machinability, refine grain size, and remove stresses and surface oxides.