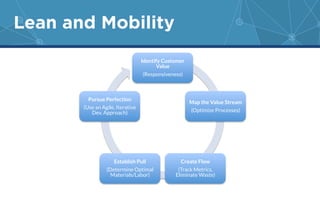

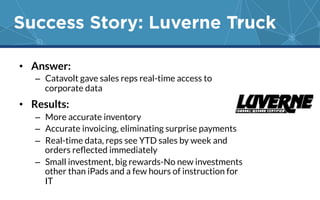

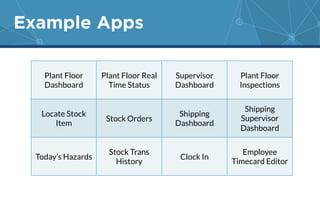

The document discusses the evolution of mobile applications in manufacturing, emphasizing the transition from mobile device management (MDM) to enterprise mobility management (EMM) and the importance of managing apps for operational excellence. It highlights opportunities for process improvements, such as optimizing workflows and enhancing decision-making through better data access. Success stories illustrate how companies like PCM and Luverne Truck effectively utilized mobile apps to increase efficiency and reduce operational costs.