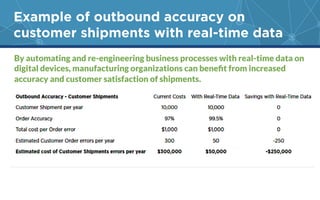

This document discusses how real-time data access on mobile devices can help manufacturing organizations improve operational excellence. It provides examples of how real-time data can streamline maintenance processes, quality assurance, safety inspections, and reporting. The document argues that replacing paper-based processes with digital tools allows manufacturing teams to address issues more quickly and make real-time decisions that improve productivity, customer satisfaction and ROI.