The document provides a comprehensive overview of Six Sigma, explaining its definition, methodology, and importance in improving process capability and reducing waste. It discusses the historical development of Six Sigma, its statistical foundations, and emphasizes the DMAIC framework for achieving high quality standards. The document also addresses the challenge of achieving Six Sigma levels in processes and the tools available for continuous improvement.

![What is Six Sigma?

Definitions - ASQ

• Six Sigma is a philosophy

– This perspective views all work as processes that can be defined,

measured, analyzed, improved and controlled. Processes require inputs (x)

and produce outputs (y). If you control the inputs, you will control the

outputs: This is generally expressed as y = f(x).

• Six Sigma is a set of tools

– The Six Sigma expert uses qualitative and quantitative techniques to drive

process improvement. A few such tools include statistical process control

(SPC), control charts, failure mode and effects analysis and flowcharting.

• Six Sigma is a methodology

– This view of Six Sigma recognizes the underlying and rigorous approach

known as DMAIC (define, measure, analyze, improve and control). DMAIC

defines the steps a Six Sigma practitioner is expected to follow, starting

with identifying the problem and ending with the implementation of long-

lasting solutions. While DMAIC is not the only Six Sigma methodology in

use, it is certainly the most widely adopted and recognized.

Source: ASQ [1]

May 16, 2012 © Strategic Modularity Inc. 2012 www.strategicmodularity.com Page 4 of 40](https://image.slidesharecdn.com/sixsigmarev1-02012-05-16-120516124222-phpapp02/85/Six-Sigma-Primer-Seeking-Meaningful-Improvments-4-320.jpg)

![What is Six Sigma?

Definitions – Lean Lexicon

• A quality standard of just 3.4 defects per one million

opportunities; 99.9996% perfect.

• Six sigma methodologies emphasize mathematical and

statistical tools to improve the quality of processes that are

already under control.

• Application follows a five-step process of define, measure,

analyze, improve, and control often referred to as DMAIC.

• The term refers to the number of standard deviations a point is

away from the mean point in a bell curve. It often is

represented as 6 sigma.

Source: Lean Lexicon [2]

May 16, 2012 © Strategic Modularity Inc. 2012 www.strategicmodularity.com Page 5 of 40](https://image.slidesharecdn.com/sixsigmarev1-02012-05-16-120516124222-phpapp02/85/Six-Sigma-Primer-Seeking-Meaningful-Improvments-5-320.jpg)

![Process Capability - Cp

A quantitative definition

SpecificationWidth

Cp =

Pr ocessCapab ility

± 4σ ± 6σ

Cp = Cp = 1 .33 Cp = Cp = 2.0

± 3σ ± 3σ

Source: Motorola [4]

May 16, 2012 © Strategic Modularity Inc. 2012 www.strategicmodularity.com Page 10 of 40](https://image.slidesharecdn.com/sixsigmarev1-02012-05-16-120516124222-phpapp02/85/Six-Sigma-Primer-Seeking-Meaningful-Improvments-10-320.jpg)

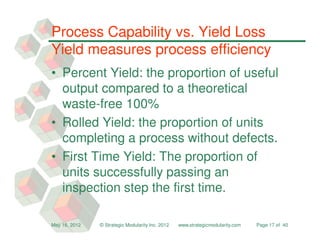

![Process Capability vs. Yield Loss

Why is Six-Sigma important?

Source: Motorola [4]

May 16, 2012 © Strategic Modularity Inc. 2012 www.strategicmodularity.com Page 14 of 40](https://image.slidesharecdn.com/sixsigmarev1-02012-05-16-120516124222-phpapp02/85/Six-Sigma-Primer-Seeking-Meaningful-Improvments-14-320.jpg)

![Process Capability vs. Yield Loss

How process shifts affect yield

Source: Motorola [4]

• At low process capability, a process shift

can produce significant yield losses.

• Six-sigma protects against yield losses

May 16, 2012 © Strategic Modularity Inc. 2012 www.strategicmodularity.com Page 15 of 40](https://image.slidesharecdn.com/sixsigmarev1-02012-05-16-120516124222-phpapp02/85/Six-Sigma-Primer-Seeking-Meaningful-Improvments-15-320.jpg)

![Process Capability vs. Yield Loss

How process shifts affect yield

• Graph shows one

process step

• Process control

– Difficult to keep most

processes centered

– Expect a shift

• Yield Loss = ƒ (Cp)

– For Cp = 1, defect rate

approaches 7%

– For Cp = 2, defect rate is

Source: Motorola [4]

negligible

May 16, 2012 © Strategic Modularity Inc. 2012 www.strategicmodularity.com Page 16 of 40](https://image.slidesharecdn.com/sixsigmarev1-02012-05-16-120516124222-phpapp02/85/Six-Sigma-Primer-Seeking-Meaningful-Improvments-16-320.jpg)

![Process Capability vs. Yield Loss

The Tyranny of Large Numbers

Source: Feiman [5]

• The Math: 0.9 x 0.9 x 0.9 x 0.9 = 0.656

• Imagine a process with hundreds of

steps: Ex. Semiconductor

Manufacturing

• Yield becomes critically important

May 16, 2012 © Strategic Modularity Inc. 2012 www.strategicmodularity.com Page 19 of 40](https://image.slidesharecdn.com/sixsigmarev1-02012-05-16-120516124222-phpapp02/85/Six-Sigma-Primer-Seeking-Meaningful-Improvments-19-320.jpg)

![Process Capability & Yield Loss

Managing Workflow Complexity

Source: Feiman [5]

• Picture shows a single process step

• Complex material flow paths

• For rejected parts, flow stops while

awaiting a disposition decision

May 16, 2012 © Strategic Modularity Inc. 2012 www.strategicmodularity.com Page 20 of 40](https://image.slidesharecdn.com/sixsigmarev1-02012-05-16-120516124222-phpapp02/85/Six-Sigma-Primer-Seeking-Meaningful-Improvments-20-320.jpg)

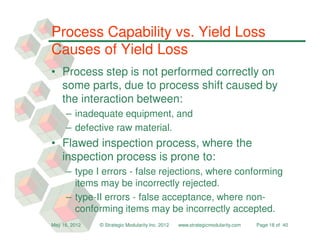

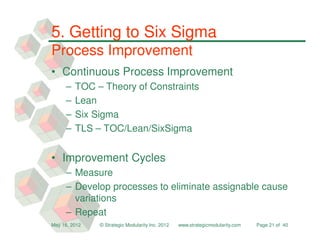

![Getting to Six Sigma

Tools to Find Assignable Cause

Source: Wordpress [6]

May 16, 2012 © Strategic Modularity Inc. 2012 www.strategicmodularity.com Page 22 of 40](https://image.slidesharecdn.com/sixsigmarev1-02012-05-16-120516124222-phpapp02/85/Six-Sigma-Primer-Seeking-Meaningful-Improvments-22-320.jpg)

![Getting to Six Sigma

Plan-Do-Check-Act Improvement Cyclss

Source: Shook [9]

May 16, 2012 © Strategic Modularity Inc. 2012 www.strategicmodularity.com Page 24 of 40](https://image.slidesharecdn.com/sixsigmarev1-02012-05-16-120516124222-phpapp02/85/Six-Sigma-Primer-Seeking-Meaningful-Improvments-24-320.jpg)

![Getting to Six Sigma

A3 Sheets PDCA Improvement Cycles

The way The better

things way to

happen work.

now.

Do

Plan Check

Act

Source: Sobek [7]

May 16, 2012 © Strategic Modularity Inc. 2012 www.strategicmodularity.com Page 25 of 40](https://image.slidesharecdn.com/sixsigmarev1-02012-05-16-120516124222-phpapp02/85/Six-Sigma-Primer-Seeking-Meaningful-Improvments-25-320.jpg)

![Improving Yield - Workflow

Managing Yield Loss Complexity

Parts Flow

Parts Flow

10% Bad

10% Bad

Source: Feiman [5]

• Picture shows a single process step

• Complex material flow paths

• For rejected parts, flow stops while

awaiting a disposition decision

May 16, 2012 © Strategic Modularity Inc. 2012 www.strategicmodularity.com Page 29 of 40](https://image.slidesharecdn.com/sixsigmarev1-02012-05-16-120516124222-phpapp02/85/Six-Sigma-Primer-Seeking-Meaningful-Improvments-29-320.jpg)

![The Tyranny of Large Numbers

Yield = ƒ (Capability, Number of Steps)

• Yield is the result,

dependent on:

– Process capability

– Number of steps

• To improve yield:

– Redesign product to

decrease part count

and improve process.

– Redesign process to

increase Cpk.

Source: Motorola [4]

May 16, 2012 © Strategic Modularity Inc. 2012 www.strategicmodularity.com Page 30 of 40](https://image.slidesharecdn.com/sixsigmarev1-02012-05-16-120516124222-phpapp02/85/Six-Sigma-Primer-Seeking-Meaningful-Improvments-30-320.jpg)

![Improving Yield – Best Process

The Robust Process

• Six Sigma Process Characteristics

– Process mean is 6σ away from USL and LSL

– Tolerates a ±1.5σ shift in process centeredness

– 3.4 Defective Parts per Million Opportunities (DPMO)

Source: Cmglee, Wikimedia Commons [8]

May 16, 2012 © Strategic Modularity Inc. 2012 www.strategicmodularity.com Page 36 of 40](https://image.slidesharecdn.com/sixsigmarev1-02012-05-16-120516124222-phpapp02/85/Six-Sigma-Primer-Seeking-Meaningful-Improvments-36-320.jpg)

![Six Sigma Primer

Bibliography

[1] ASQ, American Society for Quality, http://asq.org

[2] Lean Lexicon, 4th Edition, Lean Enterprise Institute, 2008.

[3] APICS Dictionary, 13th Edition, 2011

[4] ENG 123, “Design for Manufacturability Participant Guide,” Motorola University, 1992

[5] Feiman, Daniel, et.al “THE Book on . . . Business from A to Z: The 260 Most Important

Answers You Need to Know ,” Build It Backwards Publishing, Los Angeles CA, 2011.

[6] Tools for Root Cause Analysis, http://aacesubajou.wordpress.com

[7] Sobek, Durward K. II, and Smalley, Art “Understanding A3 Thinking: A Critical Component

of Toyota’s PDCA Management System,” Productivity Press, www.productivitypress.com ,

2008, ISBN 978-1-56327-360-5

[8] Cmglee, Six Sigma with 1.5 sigma Process shift, Wikimedia Commons

[9] Shook, John, “Managing to Learn,” Lean Enterprise Institute, 2008

May 16, 2012 © Strategic Modularity Inc. 2012 www.strategicmodularity.com Page 38 of 40](https://image.slidesharecdn.com/sixsigmarev1-02012-05-16-120516124222-phpapp02/85/Six-Sigma-Primer-Seeking-Meaningful-Improvments-38-320.jpg)