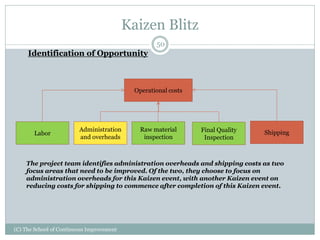

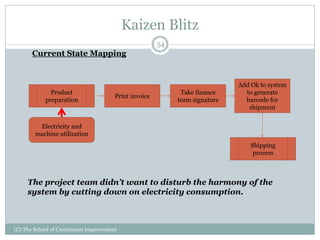

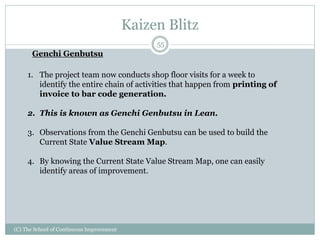

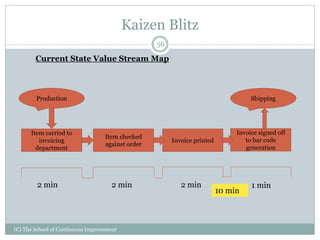

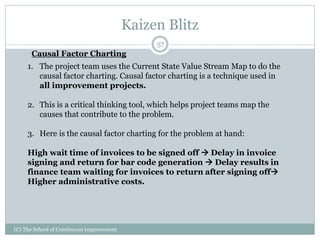

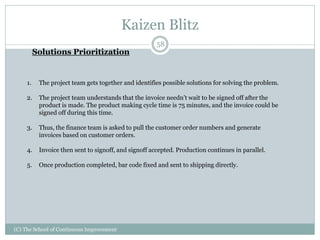

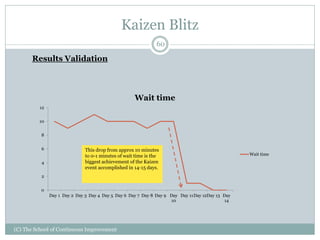

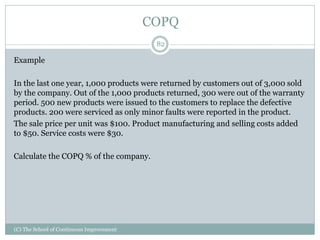

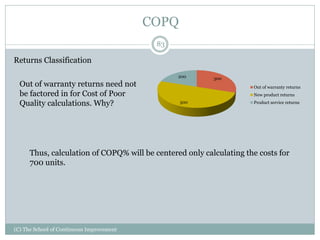

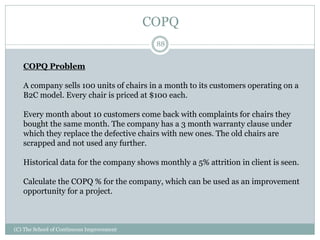

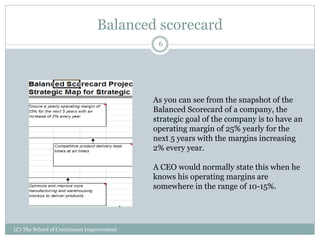

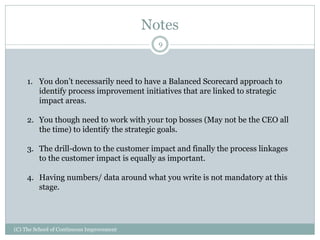

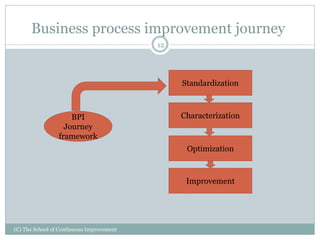

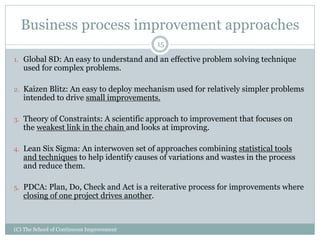

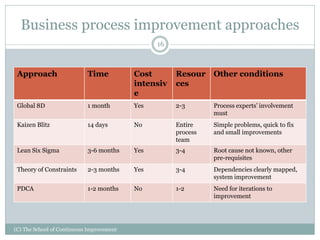

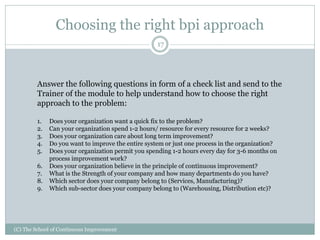

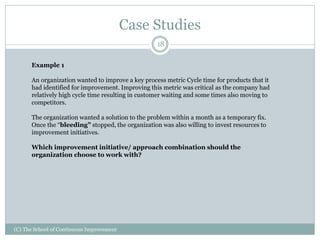

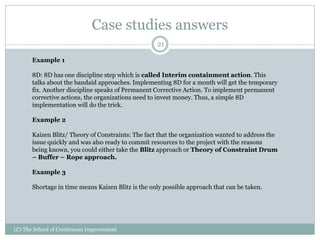

The document outlines a free training and certification program focused on process improvement, detailing key concepts such as linking strategic goals to improvement initiatives and various methodologies like Kaizen and Lean Six Sigma. It emphasizes the importance of management buy-in, data availability, and a structured approach to business process improvement through steps like standardization and optimization. Additionally, it includes case studies illustrating how to select appropriate improvement approaches based on organizational needs and constraints.

![8D

(C) The School of Continuous Improvement

28

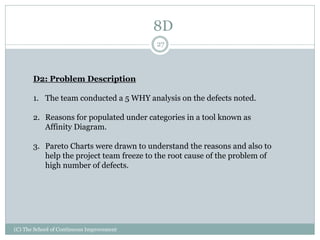

D2: Problem Description

Nailsrustwithin10days

Strengthofnailsisbad

Nailbreaks

Nailtipisnotsharp

Nailheadisnotround

Nailisnotcentred

0%

20%

40%

60%

80%

100%

0

10

20

30

40

50

60

Cumulative%

Defects

Causes

[Pareto Chart for Defects]

Vital Few Useful Many

75% of defects happen due to

Nails rusting quickly and nails

breaking earlier than expected.](https://image.slidesharecdn.com/yellowbeltprocessimprovementtrainingandcertificationmodule-150419040943-conversion-gate02/85/Yellow-belt-process-improvement-training-and-certification-module-28-320.jpg)