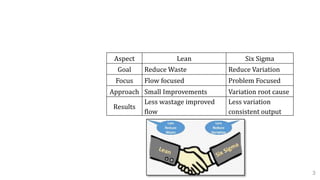

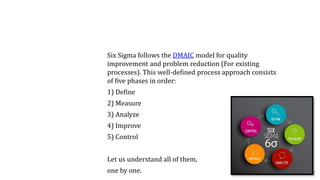

Six Sigma is a data-driven methodology for improving processes by eliminating defects. It aims for nearly flawless processes, with 99.99966% of all opportunities operating without defects. Six Sigma follows the DMAIC model, consisting of five phases - Define, Measure, Analyze, Improve, and Control. The goal is to reduce variation and maintain consistent, high-quality output through a problem-solving approach focused on addressing root causes of defects.

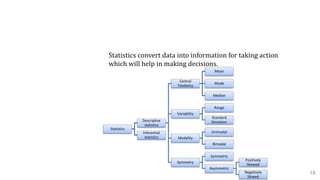

![Descriptive statistic:

It makes use of data to provide description of the

population, either through numerical calculation or

graphs,

A. Measures of Central Tendency

Mean: Represents the sum of all values in a dataset

divided by the total number of the values. A mean score is

an average score, often denoted by X.

X = (X1 + X2 + X3 + . . . + XN) / N = [Σ Xi ] / N

Mode: The middle value in a dataset that is arranged in

ascending order

Median: Defines the most frequently occurring value in a

dataset.

19](https://image.slidesharecdn.com/sixsigma-191115083616/85/Six-sigma-19-320.jpg)

![B. Variability

Standard Deviation:

The standard deviation tells you how tightly your data is

clustered around the mean (the average).

The standard deviation is a numerical value used to

indicate how widely individuals in a group vary.

σ = sqrt [Σ (Xi - X) 2 / N]

Where σ is the population standard deviation,

X is the population mean,

Xi is the I th element from the population

N is the number of elements in the population. 21](https://image.slidesharecdn.com/sixsigma-191115083616/85/Six-sigma-21-320.jpg)