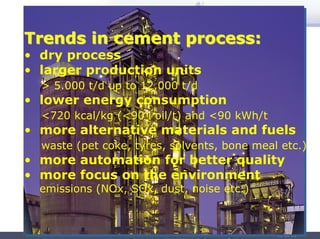

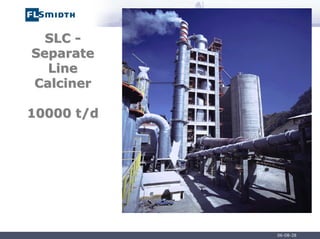

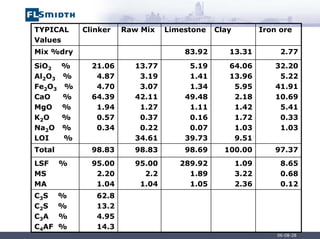

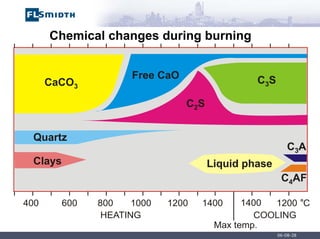

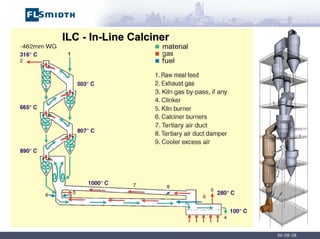

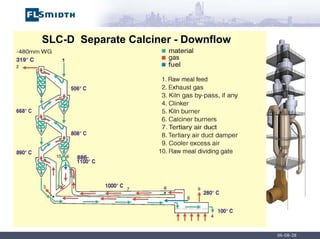

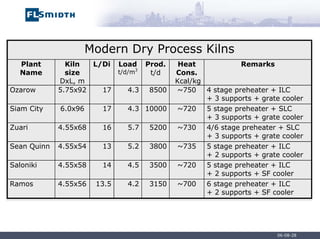

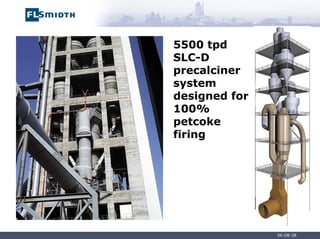

This document provides information on trends in the cement production process, including moving towards larger production units, lower energy consumption, and increased use of alternative fuels. It discusses the history of development of different kiln technologies over time, from wet kilns to modern preheater and precalciner kilns. Details are given on specific kiln systems like the Rotax, SLC, and ILC designs. Charts and diagrams show aspects like typical heat balances and consumption rates for different process stages.