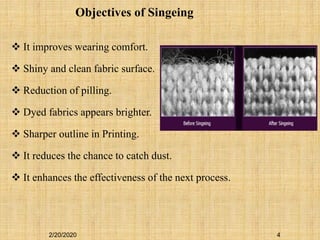

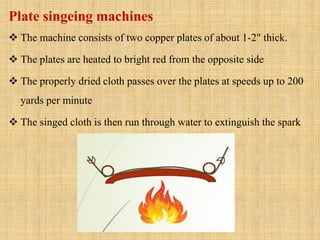

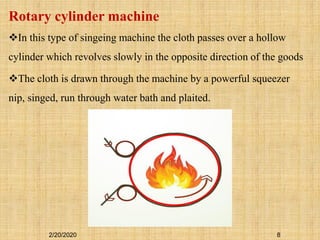

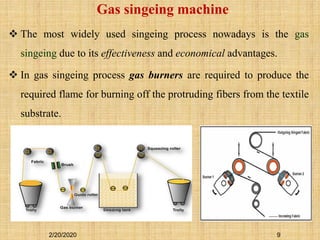

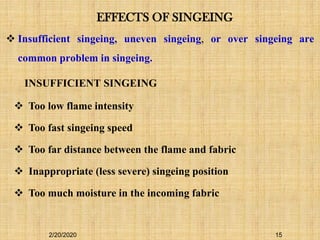

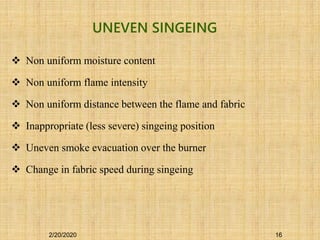

The document summarizes the singeing process of cotton fabric. Singeing involves passing fabric through a heat source to remove protruding fibers, then rapidly lowering the temperature. It improves fabric quality by making it smoother, brighter, and less prone to pilling. The key types of singeing are direct contact with a heated plate or cylinder, indirect using infrared radiation, and gas singeing using burner flames. Parameters like flame intensity, fabric speed, and distance affect the results, and uneven or excessive singeing can damage the fabric.

![ Too high flame intensity

Too slow fabric speed or too long contact between fabric and flame

Too close contact between fabric and flame [deep penetration of flame]

Inappropriate (too severe) singeing position

Over singeing results thermal damage of cotton

Horizontal singeing strips due sudden increase in tension

Vertical singeing strips due blocking of flame output

OVER SINGEING

2/20/2020 17](https://image.slidesharecdn.com/singeinglecture2-210208121154/85/Singeing-lecture-2-17-320.jpg)