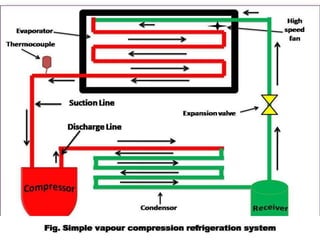

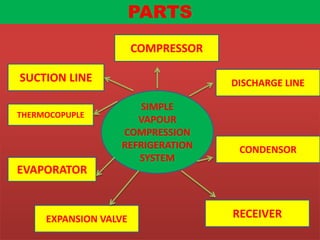

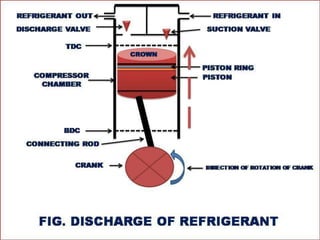

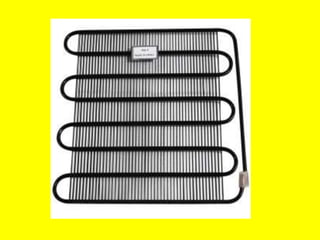

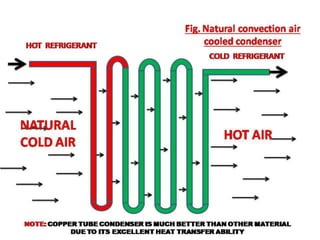

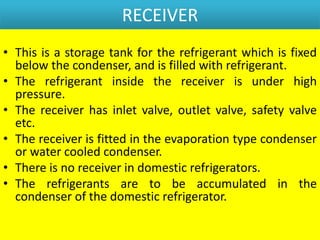

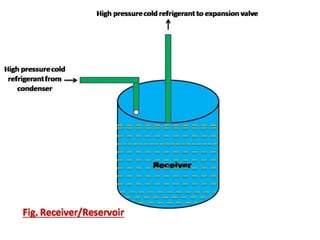

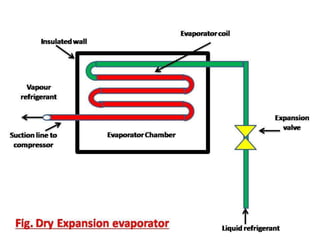

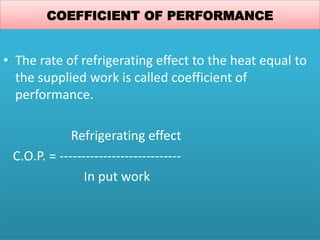

The document describes the components and functioning of a basic vapor compression refrigeration system, including the roles of the compressor, condenser, receiver, expansion valve, evaporator, and thermocouple. It highlights both advantages, such as smaller size and higher efficiency, and disadvantages, such as high initial costs and leakage prevention issues. Additionally, it touches upon concepts like refrigeration effect and coefficient of performance.