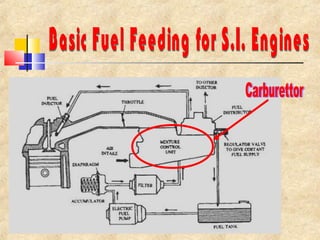

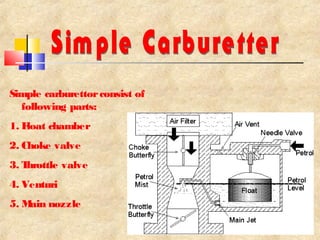

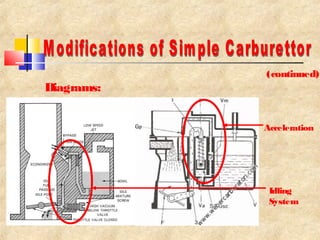

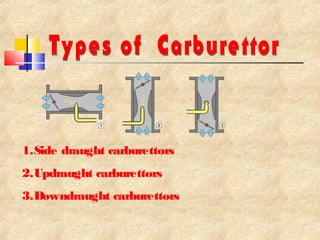

The document discusses carburetion and carburetors. It describes carburetion as the process of preparing an atomized mixture of fuel and air before admission to the cylinder. A carburetor is defined as a device that supplies a metered spray of fuel mixed with the correct amount of air for efficient combustion in the cylinder under all operating conditions. It then discusses air-fuel ratios and mixture requirements for SI engines as well as factors that affect carburetion like engine speed, intake air temperature, fuel volatility, and intake manifold design.