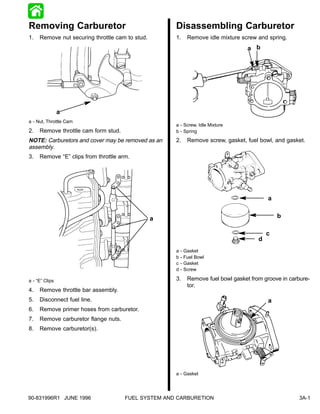

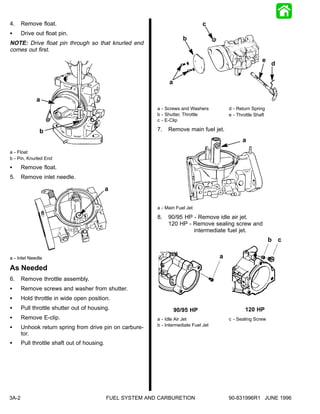

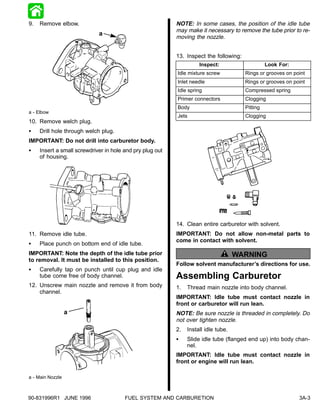

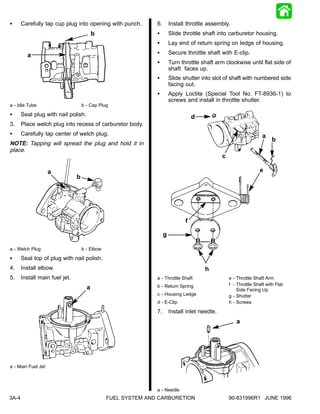

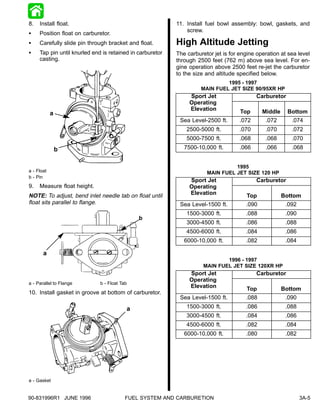

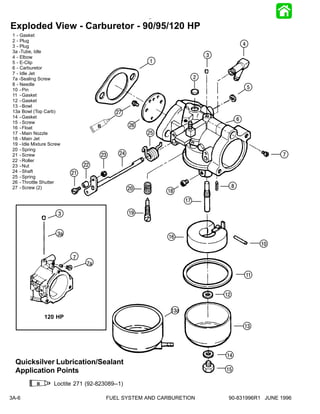

The document provides instructions for removing and disassembling a carburetor. Key steps include removing the fuel bowl, float, inlet needle, and throttle assembly. Upon disassembly, components like jets and springs should be inspected. The carburetor is then cleaned and components reassembled in reverse order. The document also provides jet sizing recommendations for high altitude carburetor adjustments. An exploded view diagram labels the main carburetor components.