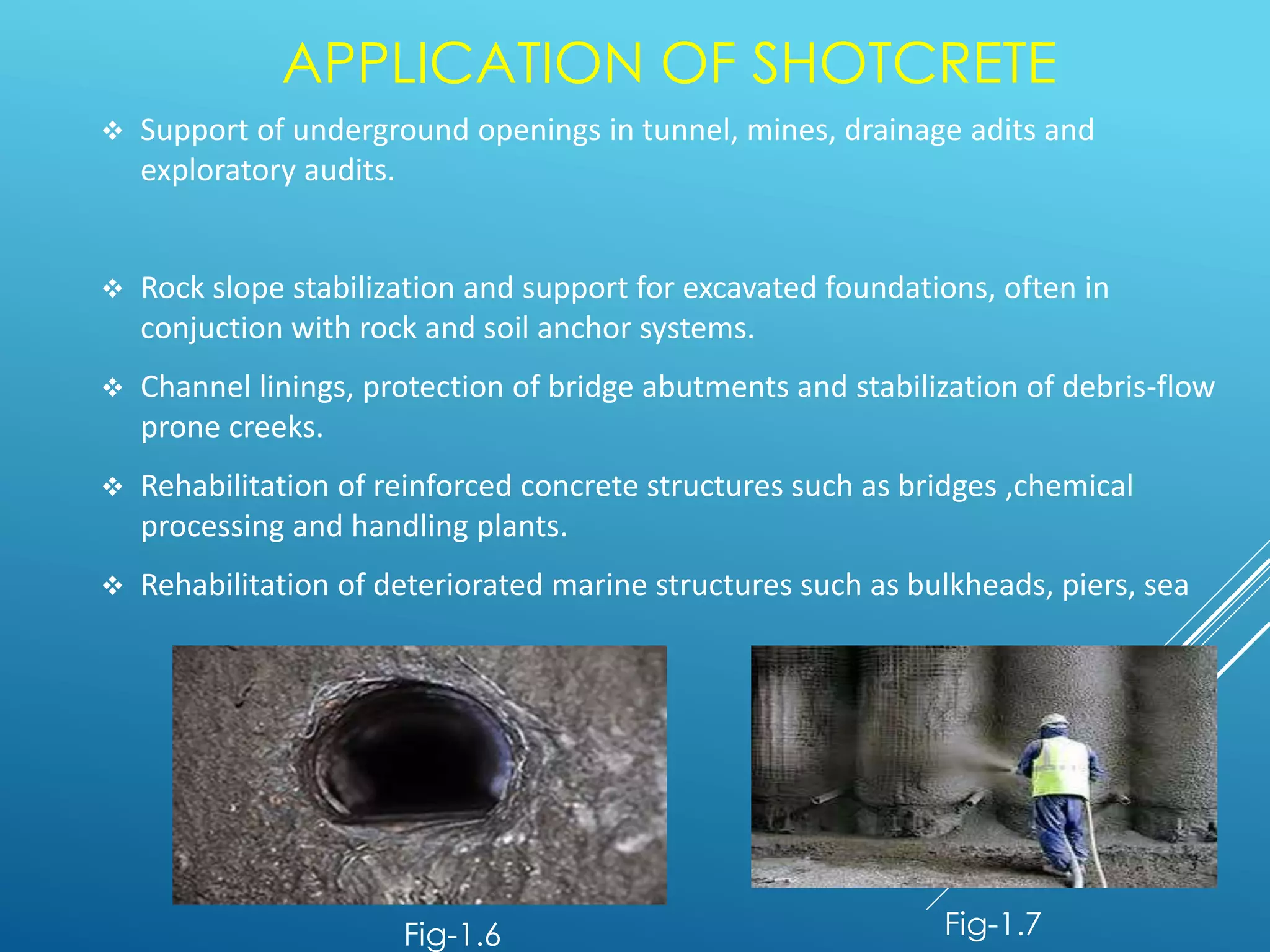

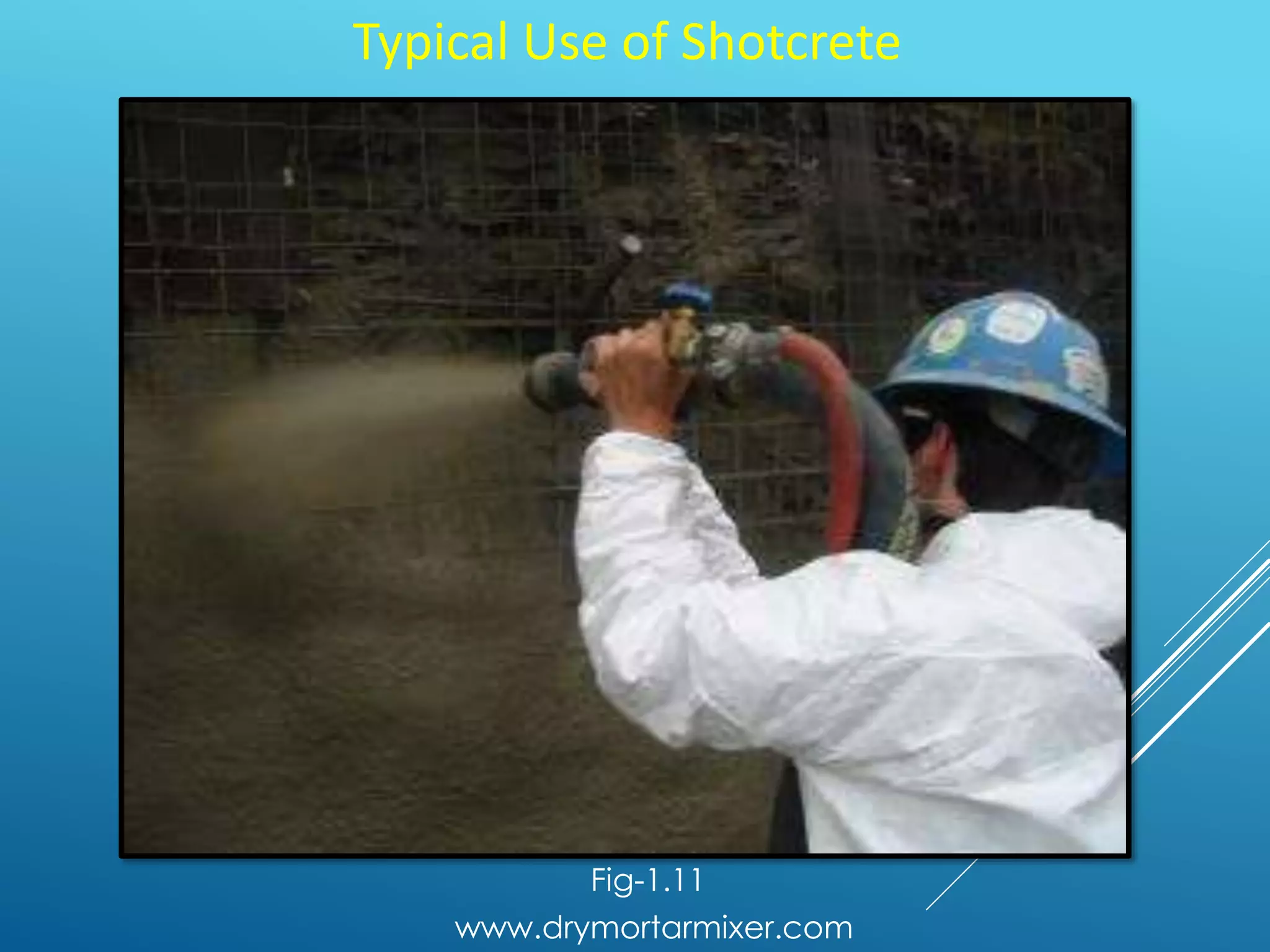

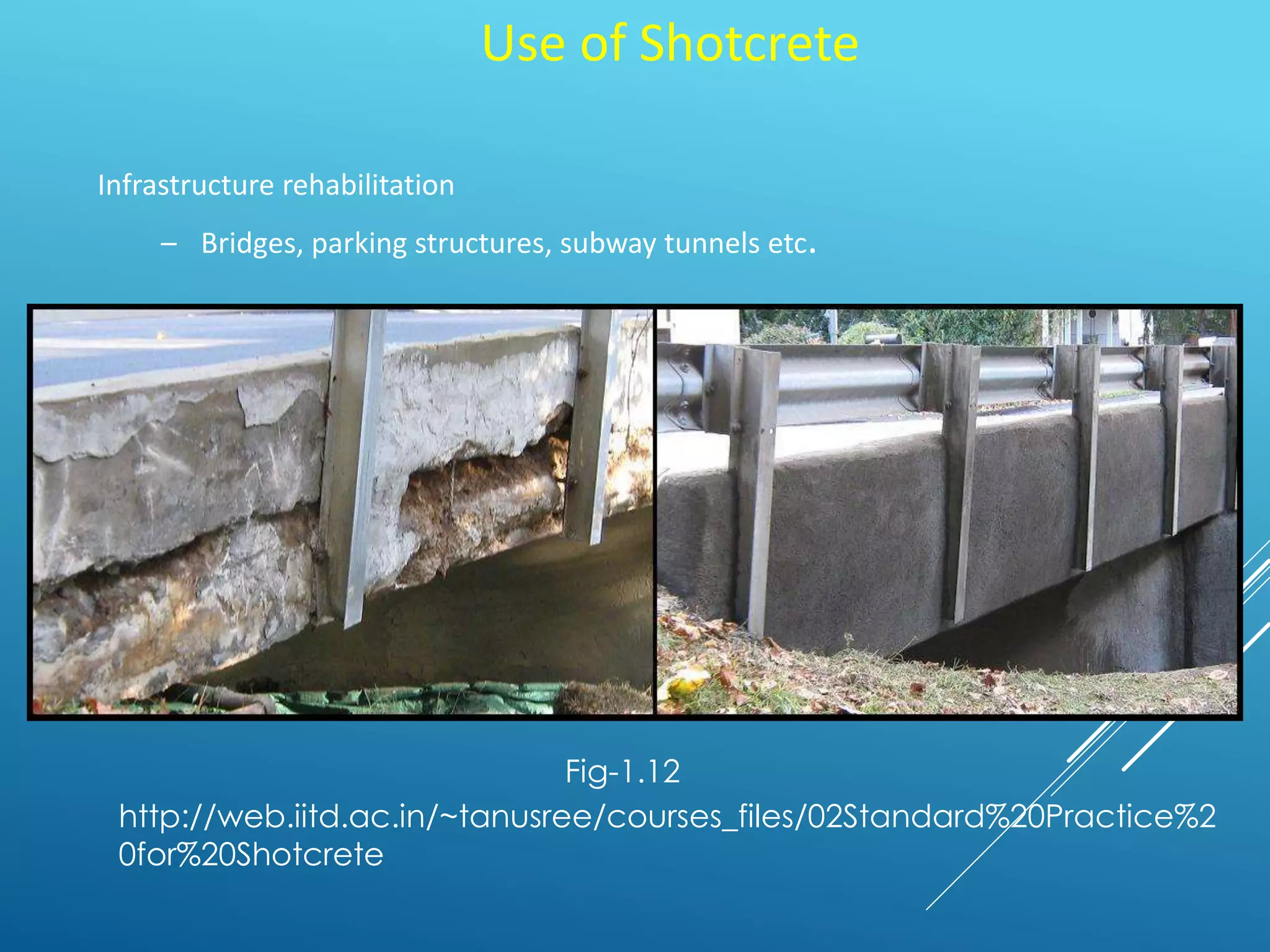

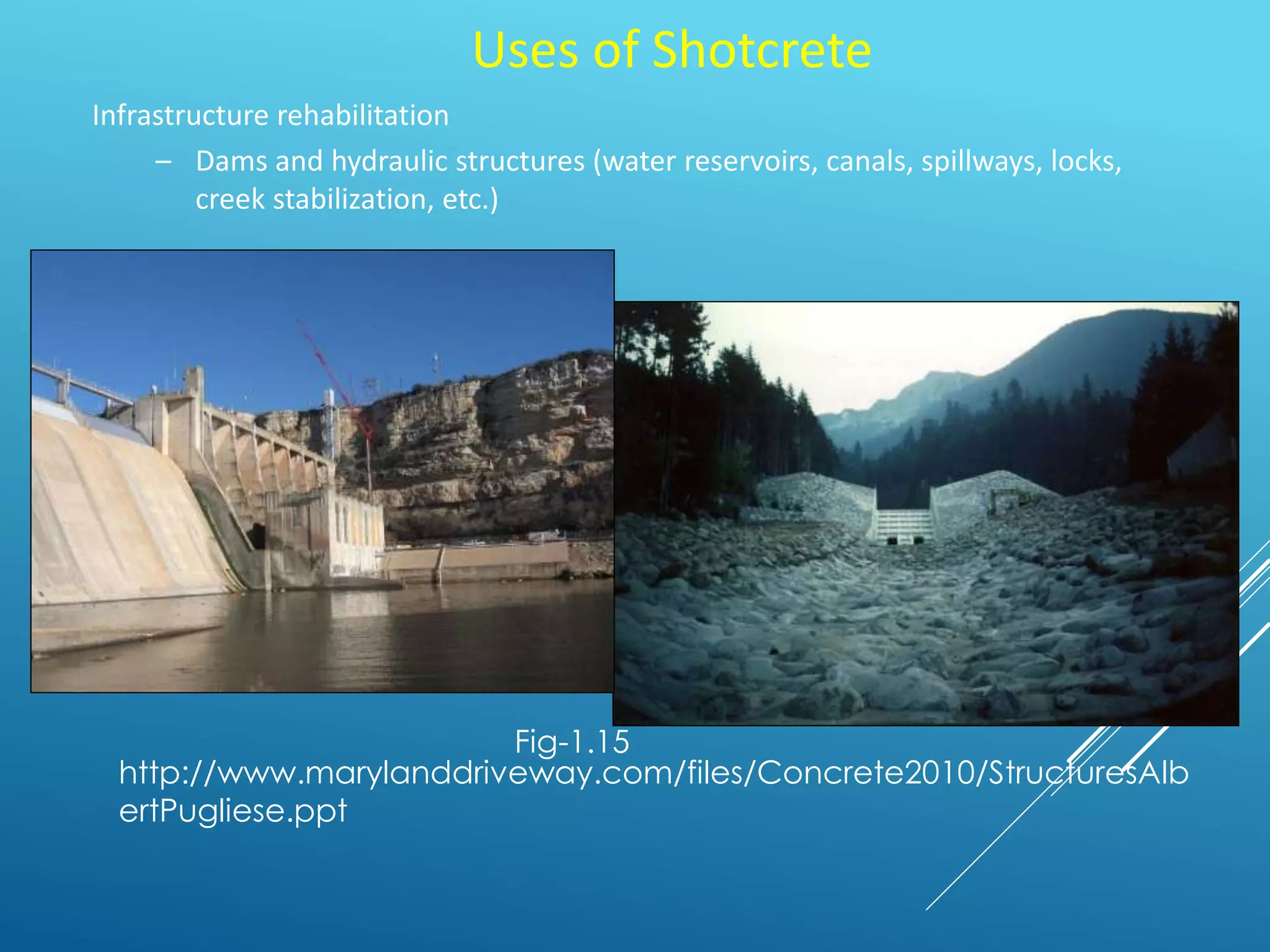

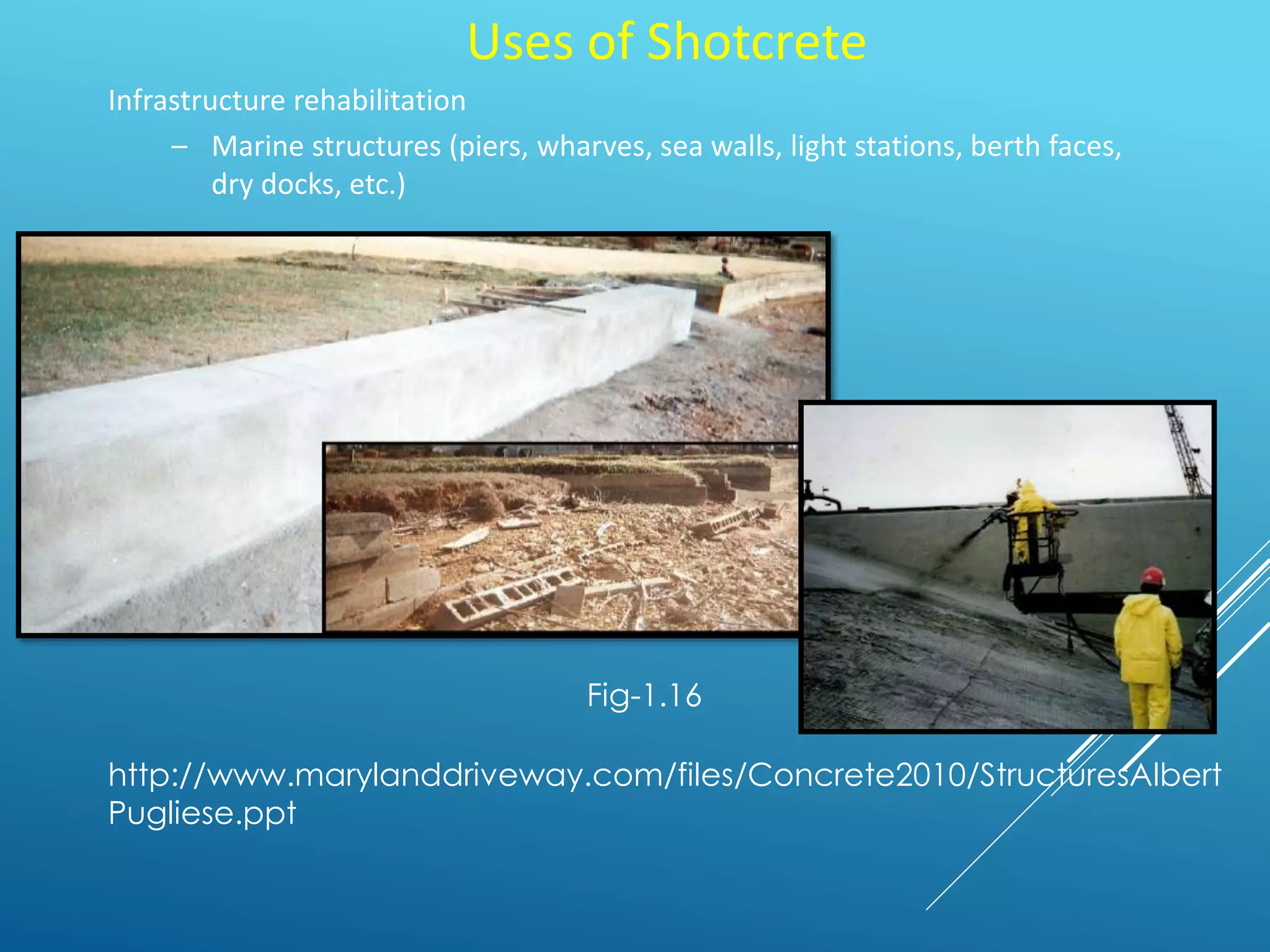

Shotcrete, also known as sprayed concrete, is a concrete conveyed through a hose and pneumatically projected at high velocity onto a surface. It undergoes compaction during placement due to the force of projection. Shotcrete can be used on irregular surfaces like domes and tunnels and has advantages over conventional concrete like requiring little framework. The document discusses shotcrete materials, equipment, processes, applications and advantages/disadvantages versus conventional concrete. Common applications include tunnel linings, slope stabilization, and infrastructure rehabilitation.