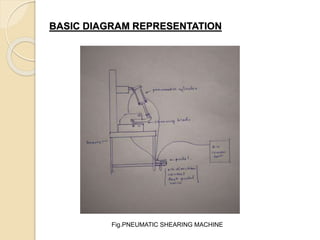

This document describes a project to design and manufacture a pneumatic shearing machine. A group of 4 mechanical engineering students will work on the project. The introduction discusses the need for new machines and techniques to increase production rates and manufacture quality products more cheaply. The working section explains how a pneumatic double acting piston and cylinder with a foot-operated directional control valve will move the shearing blade up and down. Diagrams show the basic design of the pneumatic shearing machine. The objectives are to potentially add a roller feeder, temperature sensors, a scrap collection system, and safety glass.