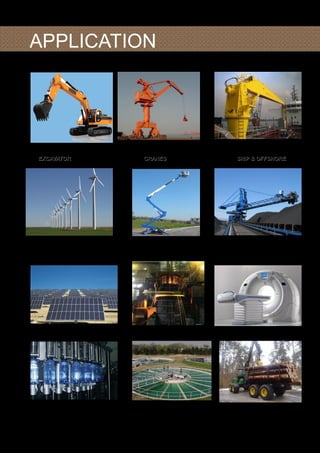

WCB Bearing Co., Ltd. specializes in slewing bearings and associated products, with a focus on quality control, technical services, and global customer relationships. Established in 2006, the company offers a wide product range and has obtained ISO9001 certification. Their products cater to various industries including metallurgy, mining, and military, emphasizing high quality and timely service.